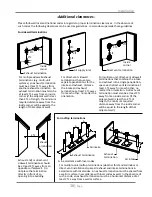

Installation

13

│

Page

‐

PVC

Venting

Illustrations

‐

<How

to

install

PVC

venting

with

the

T

‐

H2

‐

DV>

1.

Connect

the

TH

‐

PA01

PVC

adaptor*

directly

on

the

exhaust

vent

collar

of

the

T

‐

H2

‐

DV.

2.

Connect

a

4”

PVC

coupler

to

the

TH

‐

PA01

PVC

adaptor.

3.

From

the

coupler,

continue

on

the

rest

of

the

vent

run

with

4”

PVC

pipe.

<Horizontal

Installation

Diagram>

<Vertical

Installation

Diagram>

Roof

Flashing

Roof

Fire

stop

Connection

between

exhaust

vent

collar

and

PVC

piping

See

below

for

instructions.

Wall

Exhaust

vent

collar

of

the

T

‐

H2

‐

DV

(Female)

TH

‐

PA01

PVC

adaptor*

4”

PVC

coupler

4”

PVC

Straight

pipe

*TH

‐

PA01

PVC

adaptor

is

included

with

the

T

‐

H2

‐

DV.

Connection

between

exhaust

vent

collar

and

PVC

piping

See

below

for

instructions.