Installation

18

│

Page

Size

the

gas

pipe

appropriately

to

supply

the

necessary

volume

of

gas

required

for

the

T

‐

H2

‐

DV/T

‐

H2

‐

OS

(199,000

BTU/h

for

both

Natural

Gas

and

Liquid

Propane)

using

ANSI233.1/NFPA

54

in

the

USA

or

CAN/CSA

B149.1

in

Canada

or

local

codes.

Otherwise,

flow

capabilities

and

output

temperatures

will

be

limited.

4.

Re

‐

open

the

manual

gas

valve.

Check

to

see

that

there

are

no

gas

leaks.

Open

some

of

the

fixtures

that

use

the

highest

flow

rate

to

turn

on

the

T

‐

H2

‐

DV/T

‐

H2

‐

OS.

5.

Check

the

inlet

gas

pressure.

When

T

‐

H2

‐

DV/T

‐

H2

‐

OS

is

on

maximum

burn,

the

manometer

should

read

from

5.0”

to

10.5”

WC

for

Natural

gas,

from

8.0”

to

14.0”

WC

for

Liquid

Propane.

1.

Install

a

manual

gas

shut

‐

off

valve

between

the

T

‐

H2

‐

DV/T

‐

H2

‐

OS

and

the

gas

supply

line.

2.

When

the

gas

connections

are

completed,

it

is

necessary

to

perform

a

gas

leak

test

either

by

applying

soapy

water

to

all

gas

fittings

and

observing

for

bubbles

or

by

using

a

gas

leak

detection

device.

3.

Always

purge

the

gas

line

of

any

debris

and/or

water

before

connecting

to

the

gas

inlet.

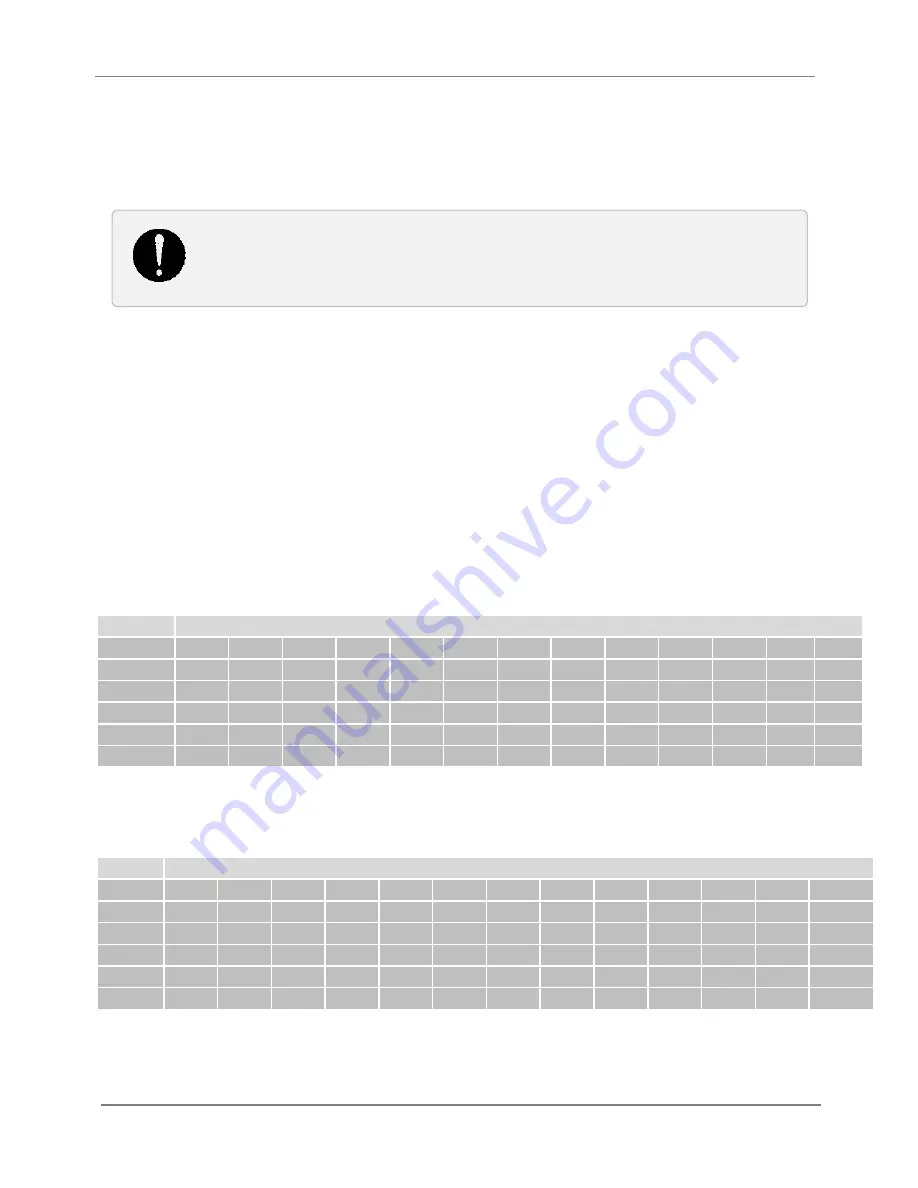

‐

Natural

Gas

Supply

Piping

‐

Maximum

Delivery

Capacity

of

Cubic

Feet

of

Gas

per

Hour

of

IPS

Pipe

Carrying

Natural

Gas

of

0.60

Specific

Gravity

Based

on

Pressure

Drop

of

0.5”

WC

Based

on

Energy

Content

of

1000

BTU/Cubic

Ft.:

T

‐

H2

‐

DV/T

‐

H2

‐

OS

requires

199

Cubic

Ft./hr.

Unit:

Cubic

Feet

per

Hour

Pipe

Size

Length

in

Feet

Inches

10’

20’

30’

40’

50’

60’

70’

80’

90’

100’

125’

150’

200’

¾”

363

249

200

171

152

138

127

118

111

104

93

84

72

1”

684

470

377

323

286

259

239

222

208

197

174

158

135

1

¼”

1,404

965

775

663

588

532

490

456

428

404

358

324

278

1

½”

2,103

1,445

1,161

993

880

798

734

683

641

605

536

486

416

2”

4,050

2,784

2,235

1,913 1,696 1,536 1,413 1,315 1,234

1,165

1,033

936

801

‐

Propane

(LP)

Gas

Supply

Piping

‐

Maximum

Capacity

of

Propane

(LP)

Gas

Based

on

11”

WC

supply

pressure

at

a

0.5”

WC

pressure

drop

Unit:

kBTU

per

Hour

Pipe

Size

Length

in

Feet

Inches

10’

20’

30’

40’

50’

60’

70’

80’

90’

100’

125’

150’

200’

¾”

567

393

315

267

237

217

196

185

173

162

146

132

112

1”

1,071

732

590

504

448

409

378

346

322

307

275

252

213

1

¼”

2,205

1,496

1,212

1,039

913

834

771

724

677

630

567

511

440

1

½”

3,307

2,299

1,858

1,559 1,417 1,275 1,181 1,086 1,023

976

866

787

675

2”

6,221

4,331

3,465

2,992 2,646 2,394 2,205 2,047 1,921 1,811

1,606 1,496

1,260

For

more

information,

please

see

the

next

page.