46

Page

Remote

Green

LED

Malfunction

description

Diagnosis

031

One Time

Incorrect DIPswitch

setting

•

Check the DIPswitch settings on the PCB (Part #701)

101

Five Times Warning for the

“991” error code

•

Check if the gas type of the water heater

matches

the gas supplied to it

•

Check if there is any blockage in the intake air and/

or exhaust

•

If the water heater is installed as a direct-vent

system, check whether there is enough distance

between the intake air terminal and the exhaust

terminal

•

Check the altitude/elevation of area of where the

water heater is installed and match the appropriate

DIPswitches

•

Check if there is grease and/or dirt in the burner (Part

#101) and the fan motor (Part #103), especially if the

water heater has been installed in a contaminated area

•

Check if the DIPswitches match gas type of the water

heater

•

Check the manifold pressure at Max and Min

•

Check combustion chamber tube (Part #117) to make

sure it is clear and securely installed

111

Three Times Ignition failure

•

Check if the Hi-limit switch (Part #411) is properly

functioning

•

Check for connection/breakage of wires (Part #412, 707,

708, 709 710), burn marks on the computer board (Part

#701), and/or soot on the flame rod (Part #108)

•

Check if there is a buzzing spark ignition sound

coming from the burner (Part #101) when water

heater prepares for combustion

•

Listen for the double “clunk” sound coming from gas

valve assembly (Part #102) when the water heater

goes into combustion

•

Check if there is leaking from heat exchanger (Part #401)

•

Check that the gas is turned on

•

Check gas supply

121

Three Times Loss of flame

•

Check if the Hi-limit switch (Part #411) is properly

functioning

•

Check for connection/breakage of wires (Part #412,

707, 708, 710), burn marks on the computer board

(Part #701), and/or soot on the flame rod (Part

#108)

•

Check if there is leaking from heat exchanger (Part #401)

•

Check gas supply

311

Two Times Outlet thermistor

failure

•

Check for connection/breakage of wires and/or

debris on thermistor (Part #407, 408, 715)

•

Check the resistance

321

Two Times Inlet thermistor

failure

341

Two Times Exhaust thermistor

failure (Indoor

models only)

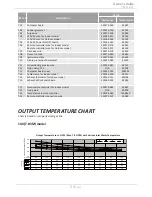

Troubleshooting

Owner's Guide

-Fault Analysis of Error Codes-

If the error code is displayed on the computer board of the water heater or remote controller and/or

temperature controller, please check the following After checking,

consult with the manufacturer