- 27 -

INITIAL OPERATION

•

Check the GAS and WATER CONNECTIONS

for leaks before firing it for the first time.

•

Open the main gas supply valve to the unit using only your hand to avoid any spark.

Never use tools. If the knob will not turn by hand, do not try to force it; call a qualified

service technician. Forced repair may result in a fire or explosion due to gas leaks.

•

Be sure to check next to the bottom of the unit because some gases are heavier than air

and may settle towards the floor.

•

Check the GAS PRESSURE.

Refer to p. 17.

•

Do not try to light the burner manually. It is equipped with an electronic ignition device

which automatically lights the burner.

•

Check for PROPER VENTING and COMBUSTIBLE AIR

to the heater.

•

Purge the GAS and WATER LINES

to remove any air pocket.

•

Do not use this water heater if any part has been submersed under water. Immediately call

a qualified service technician to inspect the water heater and to replace any damaged

parts.

CAUTION: IF YOU SMELL GAS:

•

Do not try to start the water heater.

•

Do not touch any electric switch; do not use any phone in your building.

•

Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

•

If you cannot reach your gas supplier, call the fire department.

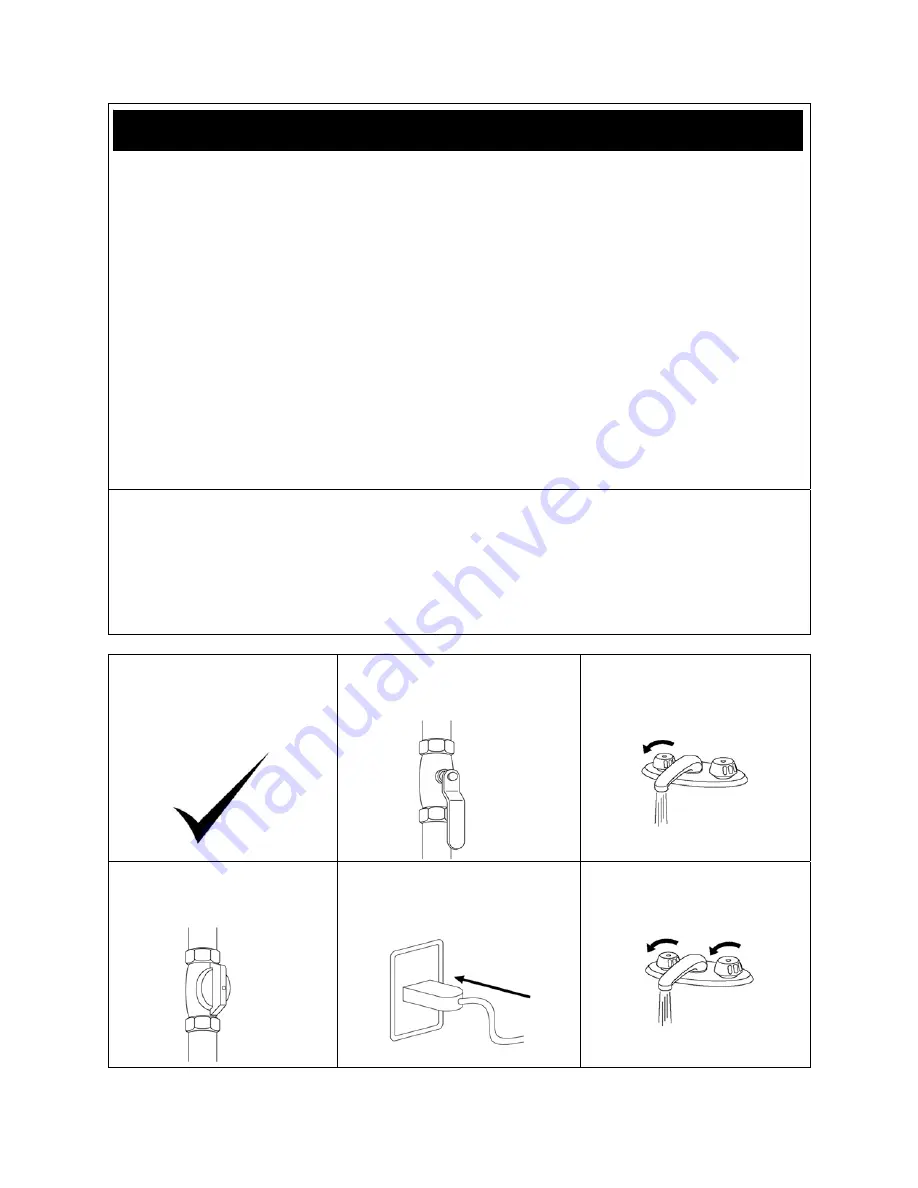

1.

Once the above checks

have been completed,

please clean filter of any

debris. Refer to p. 31 for

instructions.

2.

Fully open the manual

water control valve on the

water supply line.

3.

Open a hot water tap to

verify that water is flowing

to that tap.

Then close the hot water tap.

4.

Fully open the manual

gas control valve

installed.

5.

Turn on the 120 volt 60 Hz

power supply to the T-K3/T-

K3-Pro water heater.

6.

Now you are ready to

enjoy hours of endless

hot water.

FOR YOUR SAFETY, READ BEFORE OPERATING: