- 47 -

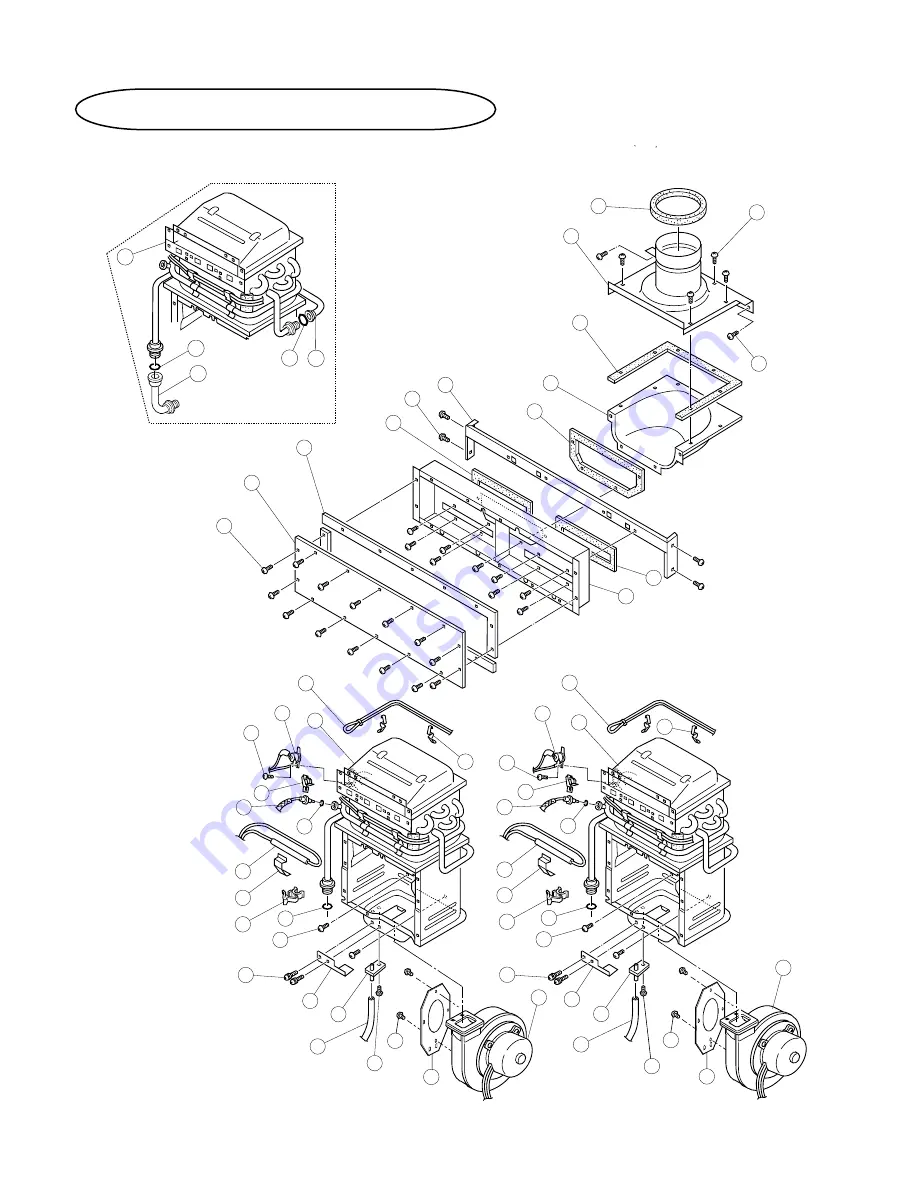

Combustion and Exhaust assembly

Other than Part# 444, Part# 445, Part# 446 and Part# 447, the

T-M50 and the T-M50 ASME share the same components.

3

132

133

136

135

137

402

401

403

404

406

407

408

409

410

411

113

412

413

414

415

113

416

405

402

401

403

404

406

407

408

409

410

411

113

412

413

414

415

113

416

405

417

133

134

131

128

130

127

129

137

113

417

138

139

139

138

T-M50 ASME

444

445

446

446

447