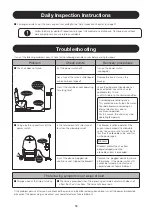

Daily Inspection Checklist

For long and safe use of the chair, inspect it according to the following checklist:

■

Daily inspection

Inspection item

Inspection procedures

Recovery procedures if there is a problem

□

Turn off the power switch. Wait for

approximately 5 sec. and turn it back on. If the

alarm still sounds, the position detectors may

be faulty. Stop using the chair and contact your

nearest dealer or Takara Belmont.

□

Operate the chair according to the “Bringing

the chair parts to their predetermined positions

with a customer sitting in the chair” section (on

page 14) of the “Operating Instructions”

chapter. If the problem persists, contact your

nearest dealer or Takara Belmont.

□

Customers may not be able to get in or out of

the chair safely. If the problem persists, contact

your nearest dealer or Takara Belmont.

□

Customers may not be able to get in or out of

the chair safely. If the problem persists, contact

your nearest dealer or Takara Belmont.

□

Customers may not be able to get in or out of

the chair safely. If the problem persists, contact

your nearest dealer or Takara Belmont.

□

Customers may not be able to get in or out of

the chair safely. Contact your nearest dealer or

Takara Belmont.

□

If the chair wobbles or produces strange noise

during operation, contact your nearest dealer or

Takara Belmont.

□

If the chair parts do not stay where they are for

a while and go down by themselves, contact

your nearest dealer or Takara Belmont.

□

Continued use may cause abnormal operation

situation to your nearest dealer or Takara

Belmont.

□

Oil may be leaking from the hydraulic parts.

Stop using the chair and contact your nearest

dealer or Takara Belmont.

□

Turn on the power switch and

check that the chair is not

producing intermittent warning

beeps.

□

Step on each of the preset

switches and check that the chair

parts return properly to their preset

positions.

□

Step on the auto-return switch and

check that the chair parts return to

their initial positions (that allow the

customer to get in and out of the

chair) properly.

□

Step on the SEAT switch and

check that the seat goes up and

down.

□

Step on the BACK switch and

check that the backrest reclines

and rises.

□

Step on the LEG switch and check

that the legrest goes up and

down.

□

Check that the chair does not

wobble or produce strange noise

during operation.

□

Check that the chair parts stay

where they are for a while and do

not go down by themselves.

□

Check that the chair is not

producing a strange odour or

smoke.

□

Check that oil is not dripping on

the base or leaking from the pump

cover.

□

Operation

□

Odour

□

Oil leaks

or fire. Turn off the main switch and report the

21

Summary of Contents for ESTHE PLACE

Page 22: ...NOTE...

Page 23: ...NOTE...