30

●

To ensure that this product can be used for a long period of time, follow the procedures outlined in

“Procedures for Daily Inspections” on page 34 to 35 of this operating manual.

Always inspect this product following the procedures outlined in “Procedures for Daily

Inspections”. Continuing to use this product without performing the daily inspections may

cause malfunctions or accidents.

Daily Inspections

If the product does not operate properly after checking and repairing the above points, stop using the product immediately.

If the following problems arise, conduct the checks outlined below, before requesting repairs.

Symptom

Check this

Solution

・

Water does not come out.

・

Sounds are generated when

hot water is supplied.

・

The water temperature

is low.

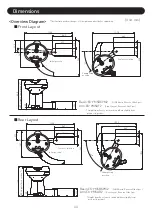

Are the water stop valves of the pipes open?

(

Refer to page 28.)

Do the sounds vary when the hot water

amount

is adjusted at the tap?

Is the temperature setup of the boiler proper?

Is the temperature setup of the thermostatic

control knob proper?

Is hair clogging the hair catcher?

Adjust the volume of the water.

(Refer to pages 14 to 15.)

Adjust the temperature setup of the

boiler to the proper temperature.

Adjust the temperature setup of the

thermostatic control knob to the proper

temperature. (Refer to page 15.)

Remove the hair clogging the hair

catcher. (Refer to page 23.)

・

The water drains poorly

from the drain outlet.

→

・

The basin unit does not

move smoothly.

Is hair tangled with the caster?

Clean the caster.

(Refer to page 29.)

→

・

The cover has come off.

Attach the cover. (Refer to page 13.)

Replace the cover if it easily comes off

repeatedly when the hose is moving.

→

→

→

・

When the hose is moved, it

makes a sound.

The sponge is protruding from the end of the

net.

The surface of the shower hose has

deteriorated and is rough. (The cover and

shower hose rub and make noise.)

Adjust the temperature setup of the

boiler to the proper temperature.

Replace the shower hose, if wiping the

surface of the shower hose with a wet

towel does not improve.

(Available at additional cost)

→

→

→

→

Before Requesting Repairs

Open the stop valves.

(Refer to pages 26 to 28.)