SAFETY

13

Preparing Precautions

Perform inspection and

maintenance daily

Failure to notice or repair machine irregularities

or damage can lead to accidents.

�

Before operating, perform the prescribed

inspections and make repairs immediately

should any irregularities be found.

�

If a failure that causes loss of control such

as steering, service brakes or engine

occurs, stop the machine motion as

quickly as possible, follow the shutdown

procedure, and keep machine securely

parked until the malfunction is corrected.

Cautions in the operator’s

compartment

�

Remove mud and grease from shoe

soles before entering the operator’s

compartment.

Pedaling the machine with the shoes

with mud and grease will cause a slip

accident.

�

Do not leave the parts or tools around the

operator’s seat.

�

Do not leave any plastic bottles in the

operator’s compartment or attach any

suction cups on the window glass. The

plastic bottle or suction cup act as a lens

and can cause fire.

�

Do not use the mobile phone during

traveling or working.

�

Do not bring combustibles or explosives

into the operator’s compartment.

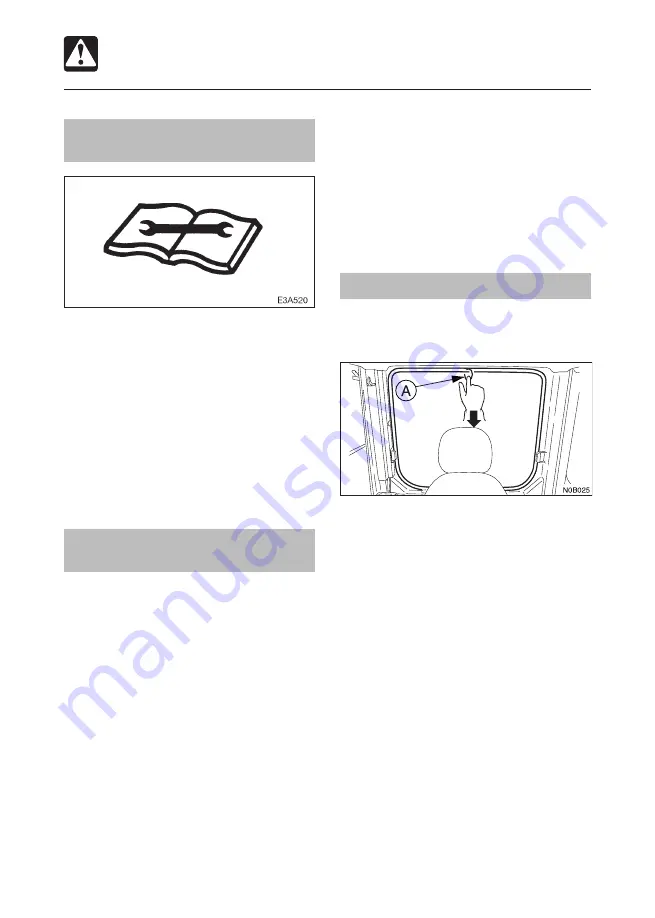

Emergency Exit

If you should become trapped inside the

cab, remove the rear window to get out.

In case of emergency

1. Pull off ring (A) and remove the tip of the

rubber wedge.

2. Grasp the tip, pull, and remove the entire

rubber wedge.

3. Kick off the rear window. Note that the

glass may break. Be careful not to get

injured.

�

After smoking, be sure to tightly close the

lid of the ashtray to put out the match or

cigarette.

�

Do not leave the cigarette lighter in the

operator’s compartment. When the

room temperature rises, the lighter may

explore.