5-29

MAINTENANCE

EVERY 50 HOURS

Adjustment

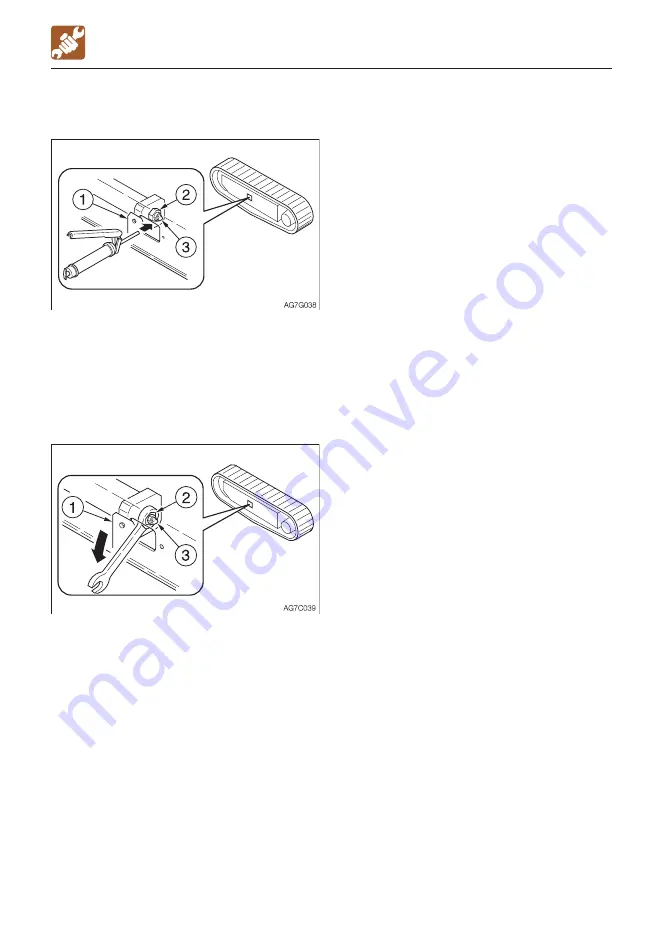

Increasing the tension

1. Remove the cover (1).

2. Using the grease gun, insert grease

through the grease fitting (3) in the grease

discharge valve (2).

3. Inspect the crawler tension.

Decreasing the tension

1. Remove the cover (1).

2. Using the spanner, slowly loosen the

grease discharge valve (2) (one turn) and

drain the grease.

If the grease does not drain easily, move

the machine forward or backward.

3. Tighten the grease discharge valve (2).

· Tightening torque: 60 to 80 N·m (44.3 to

59 ft-lb.)

Summary of Contents for TB260

Page 1: ......

Page 11: ...1 1 SAFETY...

Page 46: ...1 36 SAFETY SAFETY SIGNS DECALS Applicable machine models 126100003 or later...

Page 47: ...1 37 SAFETY SAFETY SIGNS DECALS...

Page 48: ...1 38 SAFETY SAFETY SIGNS DECALS...

Page 49: ...1 39 SAFETY SAFETY SIGNS DECALS...

Page 50: ...1 40...

Page 51: ...2 1 CONTROLS...

Page 111: ...2 61 MEMO...

Page 121: ...2 71 MEMO...

Page 135: ...3 1 OPERATION...

Page 163: ...4 1 TRANSPORT...

Page 167: ...4 5 TRANSPORT HOISTING THE MACHINE...

Page 169: ...5 1 MAINTENANCE...

Page 236: ...5 68...

Page 237: ...6 1 TROUBLESHOOTING...

Page 245: ...6 9 MEMO...

Page 264: ...6 28...

Page 265: ...7 1 SPECIFICATIONS...

Page 268: ...7 4 SPECIFICATIONS MACHINE DIMENSIONS MACHINE DIMENSIONS...

Page 270: ...7 6 SPECIFICATIONS OPERATING RANGES OPERATING RANGES...

Page 272: ...7 8 MEMO...

Page 286: ...7 22...

Page 287: ...8 1 OPTIONS OPTIONS...