5 Working Operation of the machine

58

TW9

5.3.2 Assembly of work attachments

The bearings on the lifting frame, quick-

attach system and work attachment must

be free of dirt.

The system must be relieved of pressure

before hydraulic connections are

disconnected.

Procedure for changing directly mounted work

attachments

If an attachment is hydraulically

operated, disconnect the hydraulic

connection first of all (system must be

without pressure).

•

Lower the work attachment onto the ground and

position so that it cannot tilt.

•

Remove the pin of the linkage and the pin of the

lift frame.

•

Move the lift frame out of the work attachment

and install a new one.

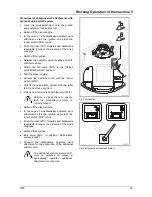

Procedure for changing work attachments with

mechanical quick-attach system

If an attachment is hydraulically

operated, disconnect the hydraulic

connection first of all (system must be

without pressure).

•

Lower the work attachment onto the ground

and position so that it cannot tilt.

•

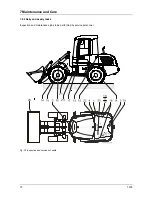

Raise pin (24/2) and open the quick-mount

hitch using the control rod (24/1) until the

locking bolts are completely retracted.

•

Check the function of the quick-attach

system lock and grease the pins if

necessary.

•

Attach another work attachment and close the

quick-mount hitch until the locking bolts are

completely extended and the lock clicks in.

•

Ensure that the work attachment and the lock

are properly seated.

•

The control rod is kept in the left-hand storage

box in the cab.

L823B22

1

2

Fig. 24 Quick-attach system

Summary of Contents for TW9

Page 6: ...Table of Contents TW9...

Page 12: ...6 TW9...

Page 42: ...3 Technical data 36 TW9...

Page 46: ...4 Operation 40 TW9 Instrument panel Fig 10 2 Operator controls...

Page 58: ...4 Operation 52 TW9...

Page 112: ...9 Appendix 106 TW9...