Maintenance and Care 7

TW9

93

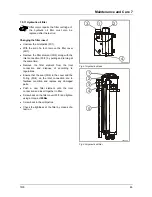

7.9.13.3 Wheel hub

Checking the axle oil level

•

Remove the inspection plug (57/1) check and

top up oil if required.

Changing axle oil

The wheel hub has a combined

inspection, filling and drain plug!

•

Turn the wheel until the screw plug (57/1) on

the hub is at the bottom.

•

Open the screw plug and catch the escaping

oil.

•

Flush out if necessary.

•

Turn the wheel to the filling and inspection

position; the inspection mark must be

horizontal.

•

Fill in oil up to the lower edge of the hole.

•

Carefully close the screw plug.

7.9.14 Wheels

Checking the tire pressure

•

Check the air pressure in accordance with the

pressure chart given in chapter 3.8.

Checking the tightness of wheel nuts

•

During the first 50 operating hours, check the

tightness of the wheel nuts (M 20x1,5) daily

and subsequently every week, and tighten to

the correct torque if necessary.

Fastening torque: 460 Nm

•

When fitting a wheel, tighten the nuts to the

correct torque crosswise in several stages.

7.9.15 Injection valves

Injection valves must be checked by your service

specialist.

7.9.16 Control cog belt for drive motor

The toothed belt must be replaced by your service

specialist.

Ölstand

Level

1

L834-057

Ablaßstellung/Drain

Fig. 57 Wheel hub

Summary of Contents for TW9

Page 6: ...Table of Contents TW9...

Page 12: ...6 TW9...

Page 42: ...3 Technical data 36 TW9...

Page 46: ...4 Operation 40 TW9 Instrument panel Fig 10 2 Operator controls...

Page 58: ...4 Operation 52 TW9...

Page 112: ...9 Appendix 106 TW9...