④

Thank you for purchasing our ”intelligent” quad

photoelectric beam.

This unit will provide long and dependable service

when properly installed.

Please read the Instruction Manual carefully to ensure

correct and effective use.

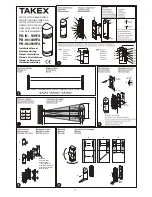

Product description

Parts description

1

A

-

Cover

B

-

View finder

C

-

Mirror

D

-

Horizontal fine adjustment screw

E

-

Vertical adjustment screw

F

-

Terminals

G

-

Tamper switch

H

-

Gain lock switch (Receiver only)

I

-

Functions indications (see R to AF)

J

-

Mirror

K

-

Adjustment dial

L

-

Shading plate

M

-

Mounting plate

N

-

Bracket

O

-

Knockout

P

-

Pole cover

Q

-

Knockout

R

-

Operation LED

S

-

Beam power (set to H at factory)

T

-

Beam channel (frequency 1-4; 1ch. set at

factory)

U

-

Sensitivity attenuation LED

V

-

Alarm LED

W

-

Beep (Alignment tone) switch (set to OFF at

factory)

X

-

Response time adjustment (set to 0.05sec.

at factory)

Y

-

Monitor jack

Z

-

Memory LED

AA

-

Beam channel (frequency 1-4; set to 1ch. at

factory)

AB

-

Alarm output selector (set to N/C at factory)

AC

-

Memory selector (set to Manual at factory)

AD

-

Enviromental output selector

(set to N/C at factory)

AE

-

Environmental output terminal

AF

-

Remote control input terminal

Wiring distance between sensor and

control panel

Installation height

In most cases, the beam should be installed at a

height of 27" to 35". (70 cm to 90 cm)

Take into consideration the beam spread of each

model type in order to avoid potential reflection from

the ground surface or nearby objects. (see table

3

)

Mounting

The units can be easily mounted on a pole or an even

surface.

- Alignment by mirror adjustment.

Using the adjustment dial and adjustment screws,

the mirror can move horizontally (±90°) and

vertically (±10°), allowing the sensor to work in all

directions.

Remove cover; the screw is at base of the cover

6

.

Loosen any screws that fix the sensor body to the

mounting plate and slide the mounting plate

downwards to detach it.

6

B

Wall mounting

Locating

4

A

Place the mounting plate on the wall as a drilling

template and mark the screw holes (allow for 20mm

space above the plate and 25mm below the plate.

This will provide for easy detachment of the cover

after installation.)

Drill holes in the wall.

4

B

Wooden wall: ø 3mm

Concrete wall: Refer to the specifications of the

securing plug used.

Install the sensor.

4

C

Insert a mounting screw; about 15mm of the screw

length should be projecting.

Install mounting plate on screws.

Insert cable.

Tighten screws.

Connect terminals.

Attach cover.

Seal the cable hole to prevent insects from

penetrating the unit.

4

C

The unit cannot be installed on an outlet box.

However, an outlet box can be used to provide cable

space.

Pole mounting

Drill cable hole in pole. Insert cable.

5

A

- The unit can be mounted onto a 1.66"-1.75" (38-45mm)

O.D. (outside diameter) pole.

- Drill a 1/2" (13mm) hole through the pole where the

unit will be mounted for wiring.

Remove all drilling chips and file all sharp edges

around the hole to prevent rough edges from

damaging the cable.

A rubber grommet or bush may be used if desired.

Install sensor on pole.

5

B

Attach U-brackets to pole and secure on mounting

plate with screws.

Attach sensor body.

Insert cable.

Connect terminals.

Attach covers. (Break knockouts on cover and pole

cover to adapt to pole diameter and configuration.)

Pole mounting back to back

5

C

Attach four U-brackets to poles in two pairs, one on

top of the other, facing in opposite directions (see

illustration).

Installation Manual for PB-IN-50HFA / PB-IN-100HFA / PB-IN-200HFA

This sensor is designed to detect intrusion and

initiate an alarm; it is not a burglary-preventive

device.

TAKEX is not responsible for damage, injury or losses

caused by accident, theft, Acts of God (including

inductive surge by lightening), abuse, misuse, abnormal

usage, faulty installations or improper maintenance.

The TAKEX photoelectric beam sensor (PB-IN-50HFA,

PB-IN-100HFA and PB-IN-200HFA) consists of an

infrared Transmitter and Receiver.

It's designed to be “AND” gated – an alarm is initiated

only when the four (quad) stacked beams are

simultaneously interrupted.

An alarm is not initiated when insects or fallen leaves

break up to three beams only.

In addition, four channels of beam frequency are

available to prevent cross-talk when multiple units are

stacked or multiple units are lined up.

Through the Programmed AGC function the sensitivity is

automatically increased in bad weather to contend with

fog, rain or frost.

PB-IN-50HFA

12V

24V

AWG20 (ø0.8 mm) 800' (244 m) 5,600' (1,710 m)

AWG18 (ø1.0 mm 1,250' (381 m) 8,800' (2,680 m)

AWG17 (ø1.1 mm) 1,500' (457 m) 10,500' (3,200 m)

AWG16 (ø1.25 mm) 1,950' (595 m) 13,500' (4,000 m)

AWG15 (ø1.4 mm) 2,500' (750 m) 17,000' (5,180 m)

AWG14 (ø1.6 mm) 3,200' (976 m) 22,500' (6,860 m)

PB-IN-100HFA

12V

24V

AWG20 (ø0.8 mm) 660' (200 m) 5,100' (1,550 m)

AWG18 (ø1.0 mm) 1,100' (335 m) 7,900' (2,410 m)

AWG17 (ø1.1 mm) 1,350' (400 m) 9,600' (2,930 m)

AWG16 (ø1.25 mm) 1,750' (534 m) 12,000' (3,660 m)

AWG15 (ø1.4 mm) 2,200' (670 m) 15,500' (4,730 m)

AWG14 (ø1.6 mm) 2,900' (884 m) 20,000' (6,000 m)

PB-IN-200HFA

12V

24V

AWG20 (ø0.8 mm) 630' (192 m) 4,400' (1,340 m)

AWG18 (ø1.0 mm) 1,000' (300 m) 6,900' (2,100 m)

AWG17 (ø1.1 mm) 1,200' (366 m) 8,400' (2,560 m)

AWG16 (ø1.25 mm) 1,550' (473 m) 10,500' (3,200 m)

AWG15 (ø1.4 mm) 1,950' (595 m) 13,500' (4,000 m)

AWG14 (ø1.6 mm) 2,550' (777 m) 17,500' (5,340 m)

Maximum wiring distance when two or more sets

are connected is the value above divided by the

number of sets.

The signal line can be wired to a distance of up to

3,300' (1,000 m) with AWG22 (dia. 0.65 mm)

telephone wire.

Summary of Contents for PB-IN-50HFA

Page 2: ...TR RE TR RE TR RE TR RE TR RE TR RE RE TR 0 3sec 0 7sec 0 05sec standard...

Page 22: ...22...

Page 23: ...23...