3 MECHANICAL INSTALLATION

3.1 SELECTING THE LOCATION

· The modules are certified according to the norm IEC 61215 and others for safe operation in moderate climates.

· Do not expose the modules to chemicals.

· Do not place the modules in standing water. The junction box is splash-proof only.

· Do not install the modules near flammable gases and vapors (e.g. gas containers) or near open

flames and flammable materials. Solar modules are not explosion-proof operating equipment.

· If there is exposure to salt (i.e., marine environments) and sulfur (i.e., sulfur sources, volcanoes),

there is a risk of corrosion.

· A module is considered shade-free when it is entirely unshaded throughout the year

(e.g. by buildings, chimneys, trees). Even partial shading of the modules (e.g. by overhead lines,

dirt, snow) should be avoided.

3.2 SELECTING THE PROPER SUPPORT FRAME

Always observe the instructions and safety precautions included with the support

frames to be used with the modules. Install each module to a mounting structure:

· That is made of durable, corrosion-resistant and UV-resistant material.

· That can transfer forces on the module to the assembly substructure.

· That ensures that no mechanical stress (e.g. caused by vibrations, twisting

or expansion) is generated on the module.

· That ensures sufficient back ventilation of the module.

· That ensures long term stability.

· That will not give rise to galvanic corrosion in case of direct metal contact

(i.e. grounding lead, screws, washers, etc.)

· That allows for strain-free expansion and contraction due to natural ambient temperature variations.

3.3 MOUNTING

Modules connected in series should be installed at the same orientation and angle. Different orientations or angles

may cause a loss of power output due to the change in sunlight exposure.

· When developing the final layout of photovoltaic system, consider keeping suitable access to allow the main-

tenance and inspection works. To minimize risk in the event of an indirect lightning strike, avoid forming loops

when designing the system.

· The modules may be installed in landscape or portrait format.

· Install the module in such a way that the junction box is positioned

in the upper area of the module and the wires hang downwards.

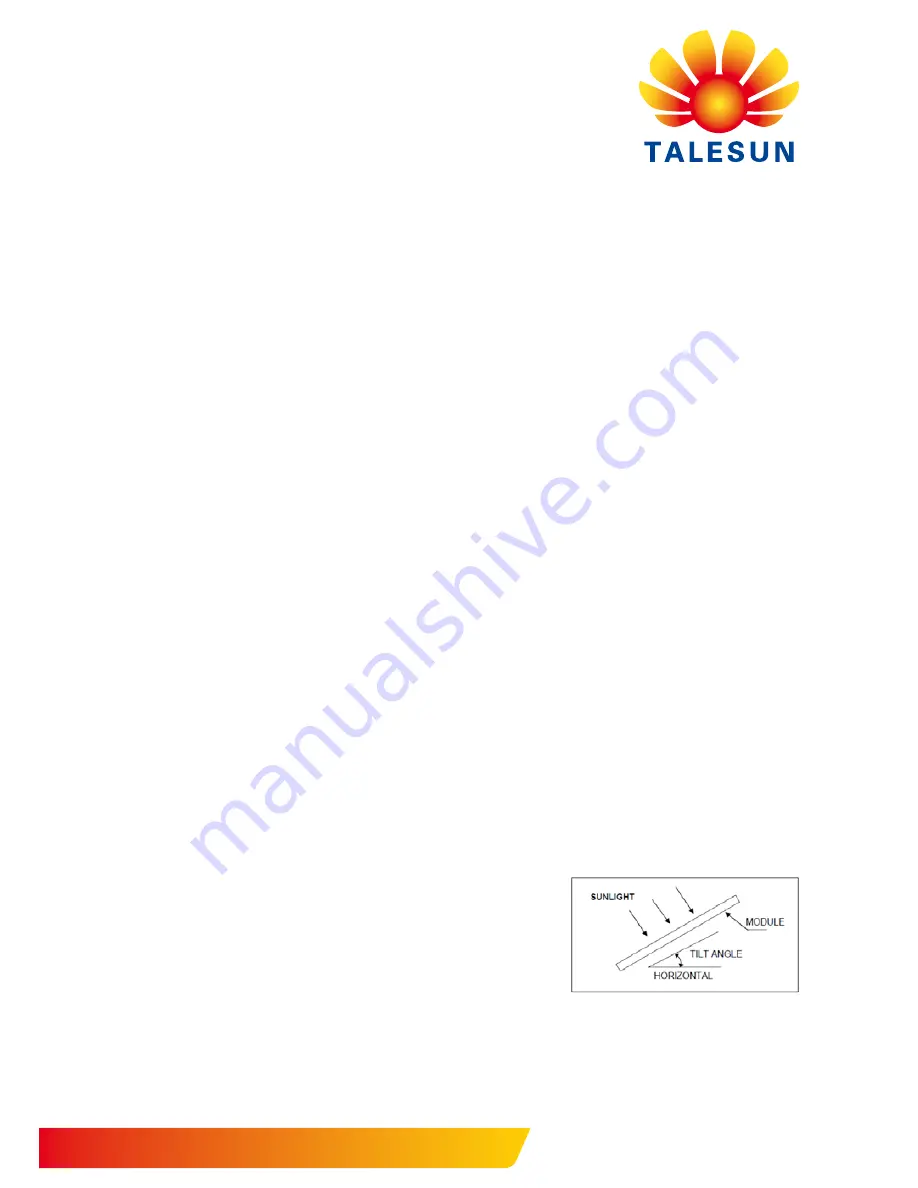

· The optimal tilt angle of the module depends on the respective lati-

tude. We recommend a photovoltaic simulation tool to ensure the

optimal orientation.

Installation manual for crystalline solar photovoltaic modules

5

Summary of Contents for TP672M-315

Page 16: ...www talesun eu com...