The Instruction Manual

LEO 320 PROFESSIONAL shredder

Page

22

of

37

TALEX Spółka z ograniczoną odpowiedzialnością

ul. Dworcowa 9c

77-141 Borzytuchom

tel. (59) 821 13 40

e-mail:

biuro@talex-sj.pl

www.talex-sj.pl

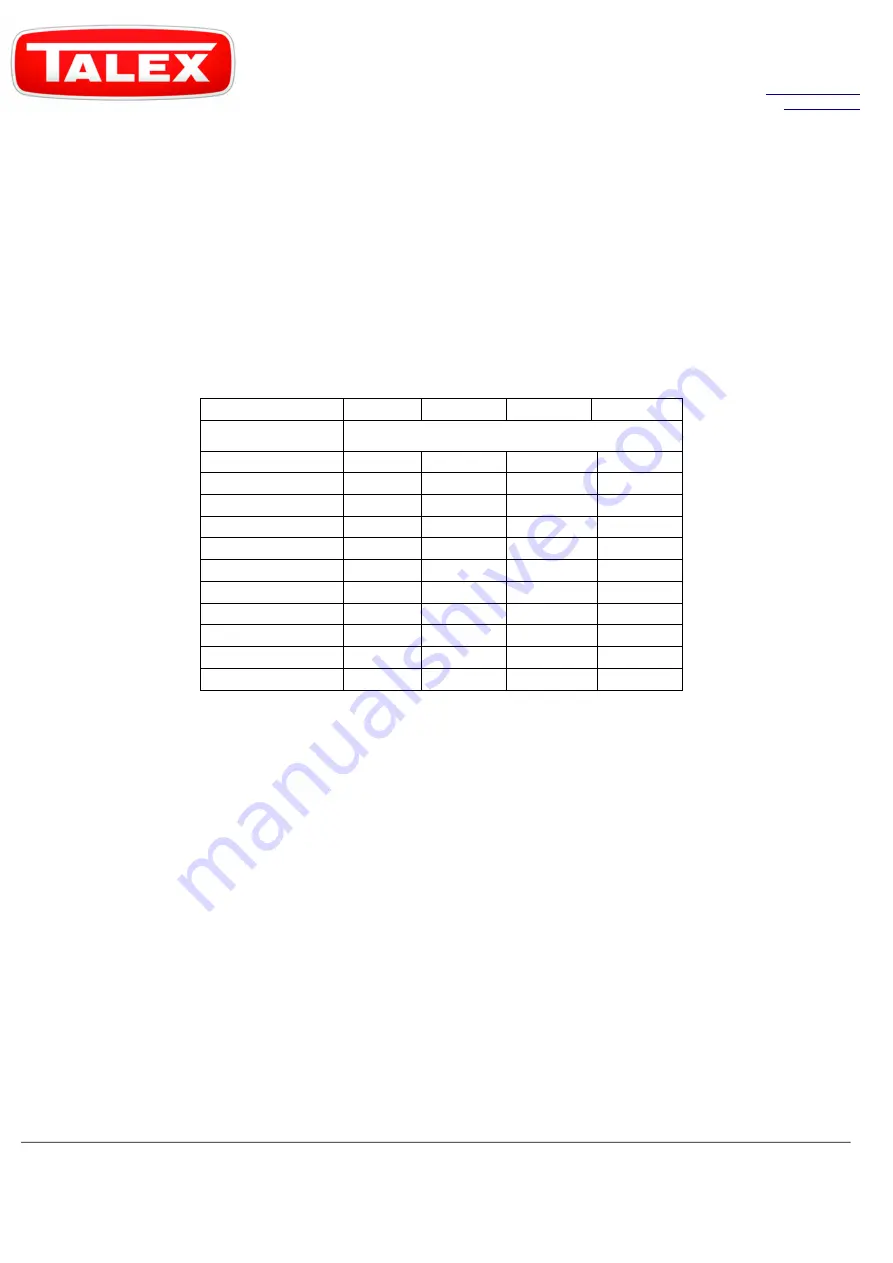

6.4

Maintenance after work

Each time your work has been completed, clean the machine and position it on a flat and

hard ground. Carry out an inspection of connections between the parts and units.

Damaged and worn out parts replace with new ones. Check all the bolt connections and

tighten the loose ones, according to the table on tightening torque values for bolts and

nuts.

All safety signs on the machine and the triangular plate distinguishing slow vehicles

should be kept clean.

Table No. 3

TIGHTENING TORQUE VALUES FOR BOLTS AND NUTS

Durability

6.8

8.8

10.9

12.9

Metric thread

Tightening torque [Nm]

M5

4.5

5.9

8.7

10

M6

7.6

10

15

18

M8

18

25

36

43

M10

37

49

72

84

M12

64

85

125

145

M14

100

135

200

235

M16

160

210

310

365

M18

220

300

430

500

M20

310

425

610

710

M22

425

580

820

960

M24

535

730

1050

1220

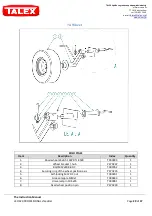

At least once a year check the level of oil in the angular transmission. Use the GL 4 80W90

type transmission oil. The oil volume in the transmission is 3.3 l.

It is also necessary to check the tension of V-belts, replace the damaged ones with new,

adjust the whole set in accordance with the instruction - 6.1 Adjustment of the belts

tension.

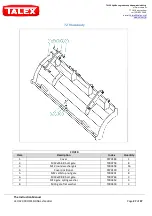

It is important to check the play of axes and shafts. Replace the axis or shaft bearings

(always in pairs) with new ones, according to the catalogue of spare parts, in case a

noticeable play is discovered. All bearings have two-sided dirt protection rings.