Summary of Contents for 424

Page 4: ...Figure 1 Model 424C Console Reader 7 Figure 2 6 and 10 Tape Reels S ATTlt Page iv...

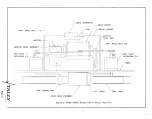

Page 10: ...I I TALLY S ATTl Page 12...

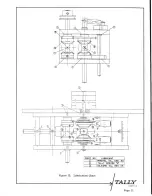

Page 21: ...s I J ____ J _ __ 1 I _ CJ O 0 E _ I TALLY SEATTLE Page 22...

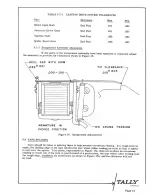

Page 23: ...C ool Figure 24 Model 424C Tape Reader SEATTLE Page 24...

Page 25: ...TALLY SEATTLE Page 26...

Page 27: ...TALLY SE ATTLE Page 28...

Page 35: ...Page 4...