Adjustments

Mechanical Adjustments

6-5

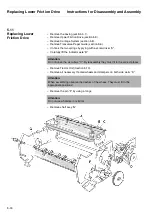

6.1.3

Adjusting Parallelism

Printhead/Platen

You must adjust parallism of printhead and platen if the printout is not satisfactory

(one side of the printed matter is smudged or too light) or in case of changing/repla-

cing the horizontal system (carriage etc.)

Necessary tool: Feeder gauge 0.05 -1.5 mm

– Remove top case (see chapter 5.1.1).

– Remove ev. Paper and Color ribbon.

– Remove transparent Paper Guide at the carriage.

– Push manually the thoothed segment on the right side to the most backward

position (in direction to the technician).

– Place the printhead at the most right position.

– Check the clearance head/platen (should be 1.4 mm; if not do adjustment

Head/Platen Gap, chapter 6.1.2)

– Move head to the most left position.

– Check the clearance head/platen by means of a feeler gauge.

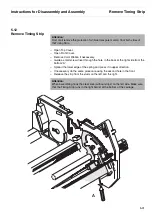

– Turn the eccentric lever “A” (see illustration on next page) on the left side wall.

Turn the lever backwards if the clearance (1.4 mm) is too big. Turn the lever to the

front if the clearance (1.4 mm) is too small.

– Install transparent Paper Guide at the carriage.

– Install the top case.

– Install the ribbon.

– Make a test printout.

Optional:

– Set AGA = Off.

– To run a visual check of the parallelism printhead/platen increase the clearance

until only a little of the printout is still to see. Compare the left with the right part of

the printout. There should only be a little difference in the blackening of the

printed matter.

– Switch printer off.

– Set AGA = ON (see chapter 4 “Testmodes and Troubleshooting”) if required.

– Adjust AGA as described in chapter 6.3.2.

Important:

The tolerance allowed is 0.05 mm.

Summary of Contents for 2365

Page 1: ...Maintenance manual Matrix printer 2365 2380...

Page 2: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 10: ...This page intentionally left blank...

Page 20: ...This page intentionally left blank...

Page 32: ...Mechanical Functions Functional Description 3 12 right mark mark mark...

Page 35: ...Functional Description Electronic Functions 3 15 2365 2380 Electronic groups...

Page 128: ...This page intentionally left blank...

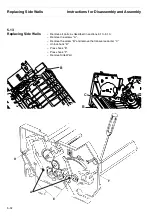

Page 134: ...Mechanical Adjustments Adjustments 6 6...

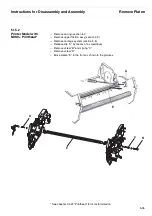

Page 136: ...Electrical Adjustments Adjustments 6 8...

Page 142: ...Housing Spare Parts and Schematics 7 2 7 1 Housing 7 1 1...

Page 144: ...Basic Printer Spare Parts and Schematics 7 4 7 2 1 Basic Printer 1 3 36...

Page 145: ...Spare Parts and Schematics Basic Printer 7 5 Basic Printer 2 3 462646...

Page 146: ...Basic Printer Spare Parts and Schematics 7 6 Basic Printer 3 3...

Page 151: ...This page intentionally left blank...

Page 164: ...Option Recognition Spare Parts and Schematics 7 24 7 10 Option Recognition...

Page 168: ...This page intentionally left blank...

Page 170: ...Tractor Complete Rear Tractor 2T Model 8 2 8 2 Tractor Complete 4 1...

Page 172: ...This page intentionally left blank...

Page 174: ...Cutting Device Option Specifications 9 2 14 6 4 12 1 5 6 11 7 13 7 8 17 2 9 3 16 15 4...

Page 176: ...This page intentionally left blank...

Page 177: ...2nd Front Tractor option 10 1 10 2nd Front Tractor option...

Page 179: ...Printer Stand Overview 11 1 11 Printer Stand 11 1 Overview...

Page 180: ...Installing the Printer Stand Printer Stand 11 2 11 2 Installing the Printer Stand 1 2 3 4...

Page 181: ...Printer Stand Installing the Printer Stand 11 3 6 8 7 5...

Page 182: ...Installing the Printer Stand Printer Stand 11 4 9 10...