Functional Description

Electronic Functions

3-35

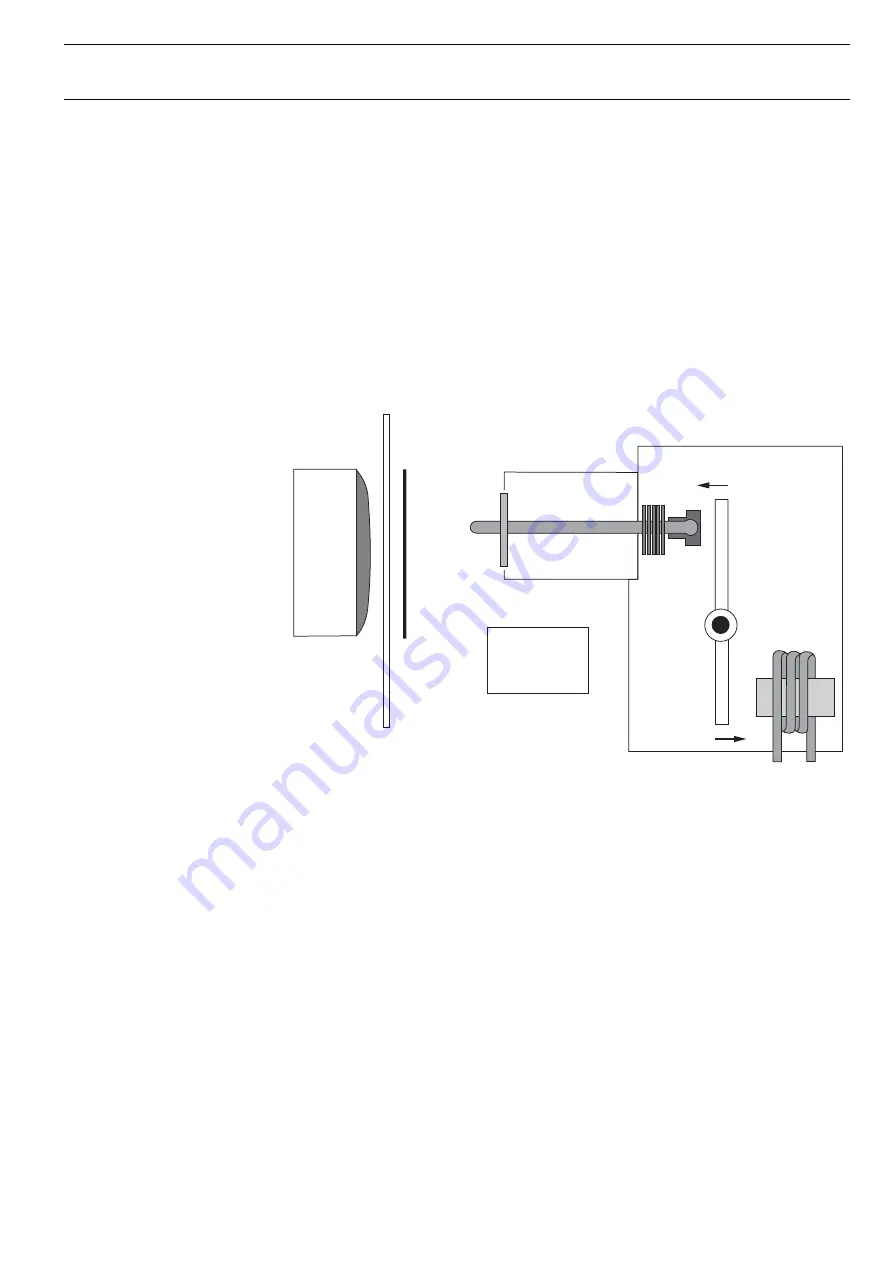

3.3.22

Printhead

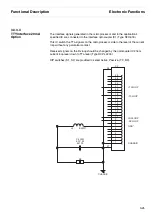

This modern ballistic printhead is driven by the needle driver section on the main

board (FT5763M, signals N1x–N24x).

General

:

The system to shoot a needle is activated by a current through a coil of the system.

One end of each coil of the needle magnet is connected to the voltage UN (+33) V

via the head cable. The return lines of the other ends of the coils are connected to the

needle drivers of the driver board. In the needle driver chip; controlled by the pro-

gram; the return lines are connected for a short time to GND. If the expected needle

current is reached the current will be chopped by hardware control.

The printhead is connected to X2 and X14 on the Connection Board. (Take care not

to loosen the pull relief clamp at the plugs when replacing printhead!).

Printhead:

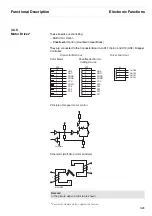

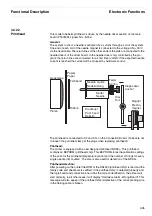

The printer is equipped with a new designed printhead NDK9+. This printhead

contains an EEPROM (printhead chip). This EEPROM stores the calibration settings

of the coils for the printhead temperature control and the number of firings for every

single needle (dot counter). The chip is also used for detection of the NDK9+.

Printhead detection:

After powering on the printer the ROM of the DS2433 (printhead chip) is read and the

family code and checksum is verified. If the printhead chip is detected properly and

the logic board and connection board has the correct identification, the printer will

start normally, in all other cases it will display "Hardware Alarm, Wrong Board". This

message will also appear if the printhead chip is defective or the corresponding wire

in the trailing cable is broken.

P

a

pier

P

a

per

F

a

r

bba

nd

Ri

bb

on

Needle G

u

ide

N

a

del

N

a

delführ

u

ng

Needle

Gegenl

a

ge

Pl

a

ten

Dr

u

ckkopf

Print he

a

d

B

a

lli

s

tic

F

uss

Foot

M

a

gnet

Elektro-

m

a

gnet

S

pring

Feder

Kl

a

pp

a

nker

Anchor

Summary of Contents for 2365

Page 1: ...Maintenance manual Matrix printer 2365 2380...

Page 2: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 10: ...This page intentionally left blank...

Page 20: ...This page intentionally left blank...

Page 32: ...Mechanical Functions Functional Description 3 12 right mark mark mark...

Page 35: ...Functional Description Electronic Functions 3 15 2365 2380 Electronic groups...

Page 128: ...This page intentionally left blank...

Page 134: ...Mechanical Adjustments Adjustments 6 6...

Page 136: ...Electrical Adjustments Adjustments 6 8...

Page 142: ...Housing Spare Parts and Schematics 7 2 7 1 Housing 7 1 1...

Page 144: ...Basic Printer Spare Parts and Schematics 7 4 7 2 1 Basic Printer 1 3 36...

Page 145: ...Spare Parts and Schematics Basic Printer 7 5 Basic Printer 2 3 462646...

Page 146: ...Basic Printer Spare Parts and Schematics 7 6 Basic Printer 3 3...

Page 151: ...This page intentionally left blank...

Page 164: ...Option Recognition Spare Parts and Schematics 7 24 7 10 Option Recognition...

Page 168: ...This page intentionally left blank...

Page 170: ...Tractor Complete Rear Tractor 2T Model 8 2 8 2 Tractor Complete 4 1...

Page 172: ...This page intentionally left blank...

Page 174: ...Cutting Device Option Specifications 9 2 14 6 4 12 1 5 6 11 7 13 7 8 17 2 9 3 16 15 4...

Page 176: ...This page intentionally left blank...

Page 177: ...2nd Front Tractor option 10 1 10 2nd Front Tractor option...

Page 179: ...Printer Stand Overview 11 1 11 Printer Stand 11 1 Overview...

Page 180: ...Installing the Printer Stand Printer Stand 11 2 11 2 Installing the Printer Stand 1 2 3 4...

Page 181: ...Printer Stand Installing the Printer Stand 11 3 6 8 7 5...

Page 182: ...Installing the Printer Stand Printer Stand 11 4 9 10...