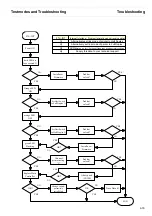

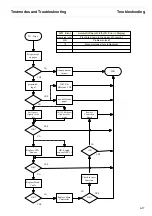

Testmodes and Troubleshooting

Printing without TopCover

4-27

4.8

Printing without Top-

Cover

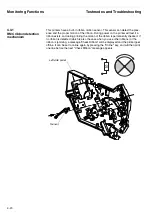

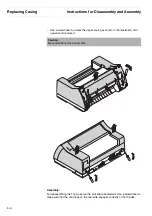

Sometimes it is usefull to look into the printer while the printer is working. (Normal-

lythis is prevented by means of an interlock sensor.)

Caution:

Take care when the printer is operating: danger of injury!

–

Open Top Cover

–

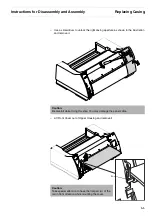

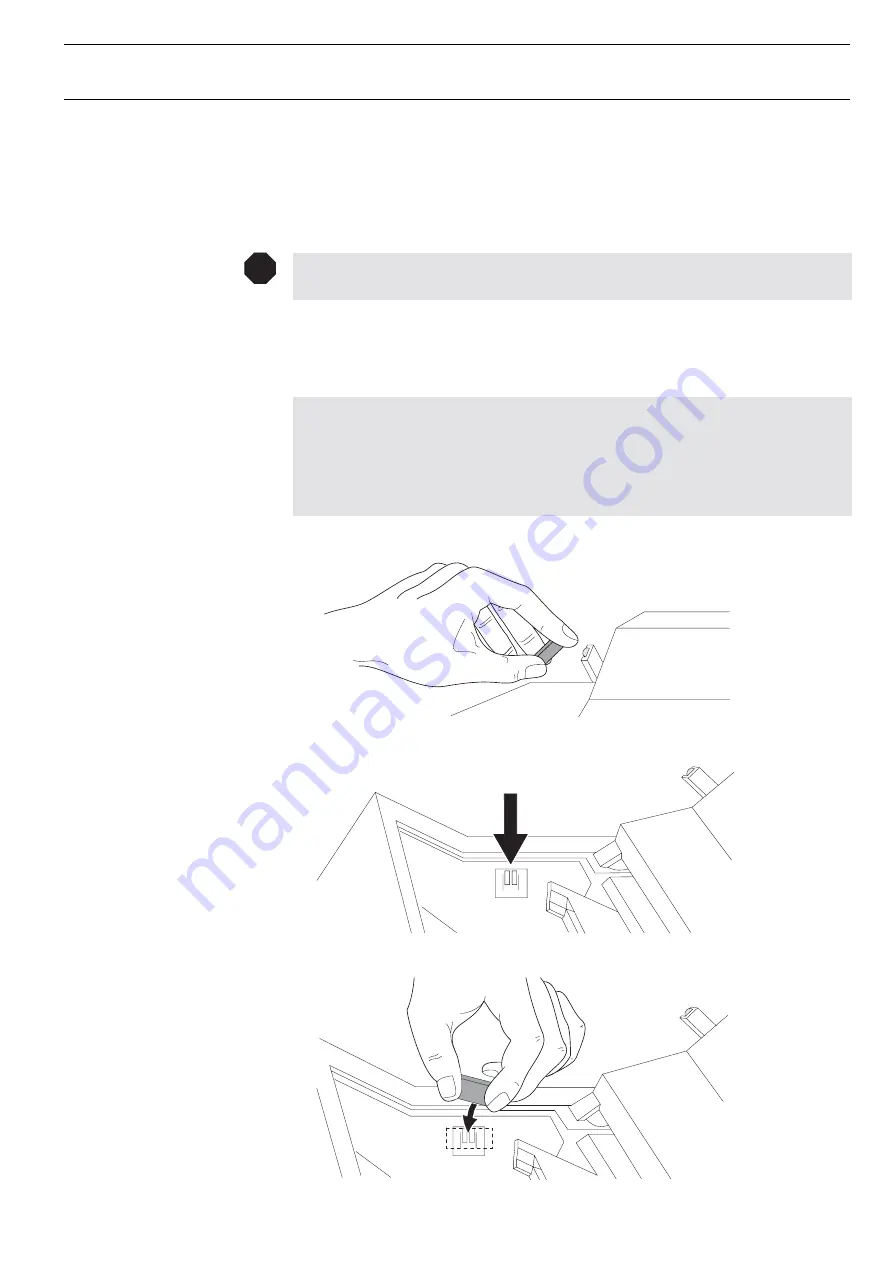

Install the magnet at the interlock hall sensor on the left side wall by means of an

adhesive tape

Attention:

It is necessary to install the magnet with south pole in direction of the hall sensor.

To obtain this it is suggested to carry out following procedure:

1. Determine the south pole by using the magnet in the Top Cover. The south pole

is repelled by the built in magnet.

2. Stick the magnet (053 528) at the place shown in the drawing.

STOP

Summary of Contents for 2365

Page 1: ...Maintenance manual Matrix printer 2365 2380...

Page 2: ...This page intentionally left blank...

Page 8: ...This page intentionally left blank...

Page 10: ...This page intentionally left blank...

Page 20: ...This page intentionally left blank...

Page 32: ...Mechanical Functions Functional Description 3 12 right mark mark mark...

Page 35: ...Functional Description Electronic Functions 3 15 2365 2380 Electronic groups...

Page 128: ...This page intentionally left blank...

Page 134: ...Mechanical Adjustments Adjustments 6 6...

Page 136: ...Electrical Adjustments Adjustments 6 8...

Page 142: ...Housing Spare Parts and Schematics 7 2 7 1 Housing 7 1 1...

Page 144: ...Basic Printer Spare Parts and Schematics 7 4 7 2 1 Basic Printer 1 3 36...

Page 145: ...Spare Parts and Schematics Basic Printer 7 5 Basic Printer 2 3 462646...

Page 146: ...Basic Printer Spare Parts and Schematics 7 6 Basic Printer 3 3...

Page 151: ...This page intentionally left blank...

Page 164: ...Option Recognition Spare Parts and Schematics 7 24 7 10 Option Recognition...

Page 168: ...This page intentionally left blank...

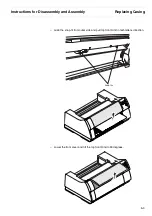

Page 170: ...Tractor Complete Rear Tractor 2T Model 8 2 8 2 Tractor Complete 4 1...

Page 172: ...This page intentionally left blank...

Page 174: ...Cutting Device Option Specifications 9 2 14 6 4 12 1 5 6 11 7 13 7 8 17 2 9 3 16 15 4...

Page 176: ...This page intentionally left blank...

Page 177: ...2nd Front Tractor option 10 1 10 2nd Front Tractor option...

Page 179: ...Printer Stand Overview 11 1 11 Printer Stand 11 1 Overview...

Page 180: ...Installing the Printer Stand Printer Stand 11 2 11 2 Installing the Printer Stand 1 2 3 4...

Page 181: ...Printer Stand Installing the Printer Stand 11 3 6 8 7 5...

Page 182: ...Installing the Printer Stand Printer Stand 11 4 9 10...