Advanced menu

User guide

98

Automatic paper motion

sensor (PMS)

You can use this function to activate or deactivate the paper motion

detection feature. When it is active, printing and paper movements

stop in case of a paper jam and an error message is output in the

display. Set the printer to test mode by pressing the

Online

key

while you switch on the printer.

Press the

Next

key (4).

Select the

PMS

menu (3).

Setting options:

Off

/

Low

/

Mid

/

High

Default setting:

Low

PMS=Low

/

Mid

/

High

: The form movements of the active paper path

are monitored. In case of a paper jam, printing and paper move-

ments stop and an error message (

paper jam

) is displayed.

Low

: Sensitivity 800/360"

Mid

: Sensitivity 600/360"

High

: Sensitivity 300/360"

PMS=Off

: A paper jam will not produce an error message.

The Paper Motion Sensor (PMS) detects any paper jam or unin-

tended paper end condition and provides efficient protection

against any paper transport problems together with the paper

end sensor. This prevents the printer from printing on jammed

paper or printing without paper. Disabling the PMS can affect

the operational reliability of your printer and should therefore

be avoided.

Confirm the setting by pressing the

Set

(1) key. Change to the next

parameter group with the

Next

key (4).

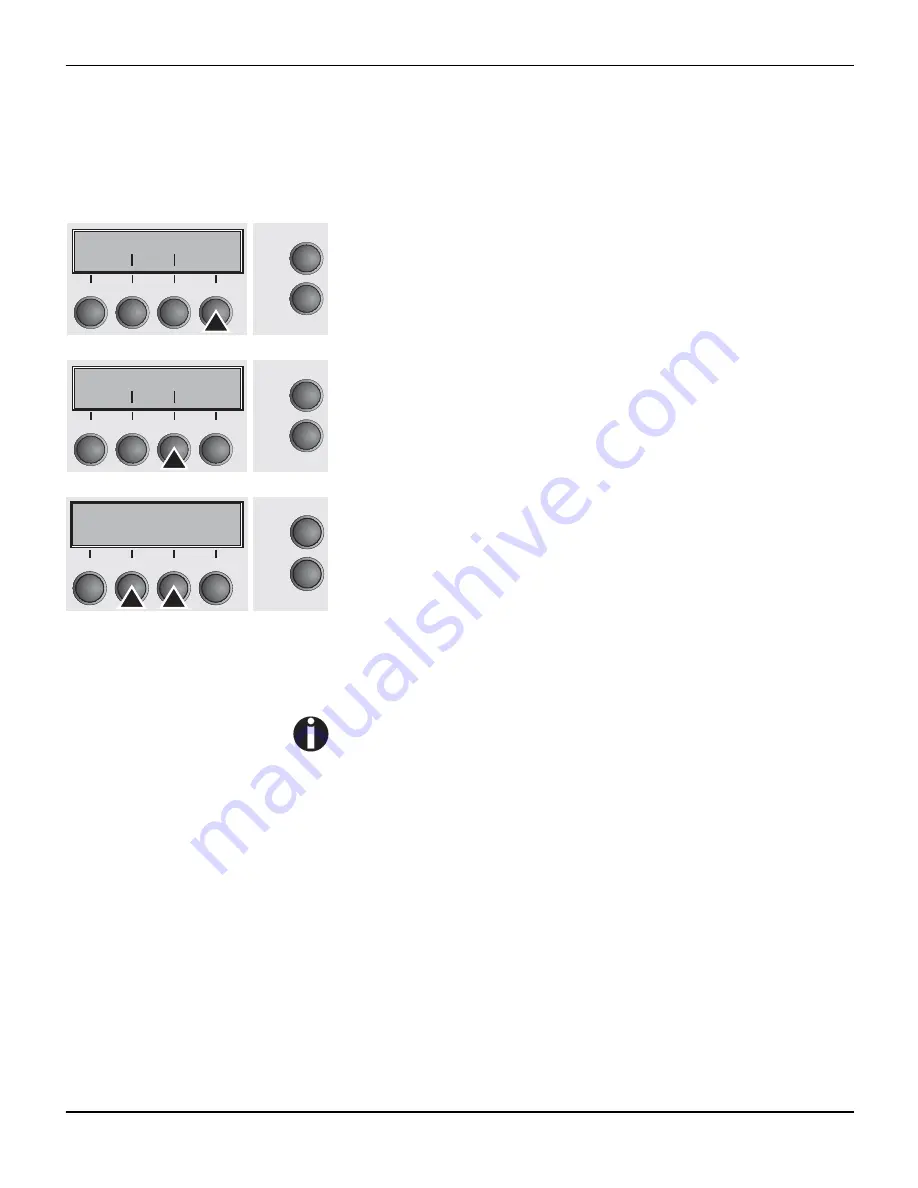

ASCII80 ASCII136

Online

Setup

Back

Next

2

1

3

4

H-Dump

PMS

Online

Setup

Back

Next

2

1

3

4

PMS=On

*

Online

Setup

Set

<

>

Exit

2

1

3

4

Summary of Contents for 2365

Page 1: ...User guide Matrix printer 2365 2380 ...

Page 2: ......

Page 10: ......

Page 14: ...Printer at a glance User guide 4 Printer in tractor mode Tractors ...

Page 16: ......

Page 38: ......

Page 46: ......

Page 62: ......

Page 100: ...The Menu User guide 90 Menu settings example ...

Page 178: ......