6 – 4

Chapter 6 Principles of Operation

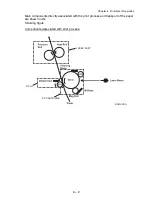

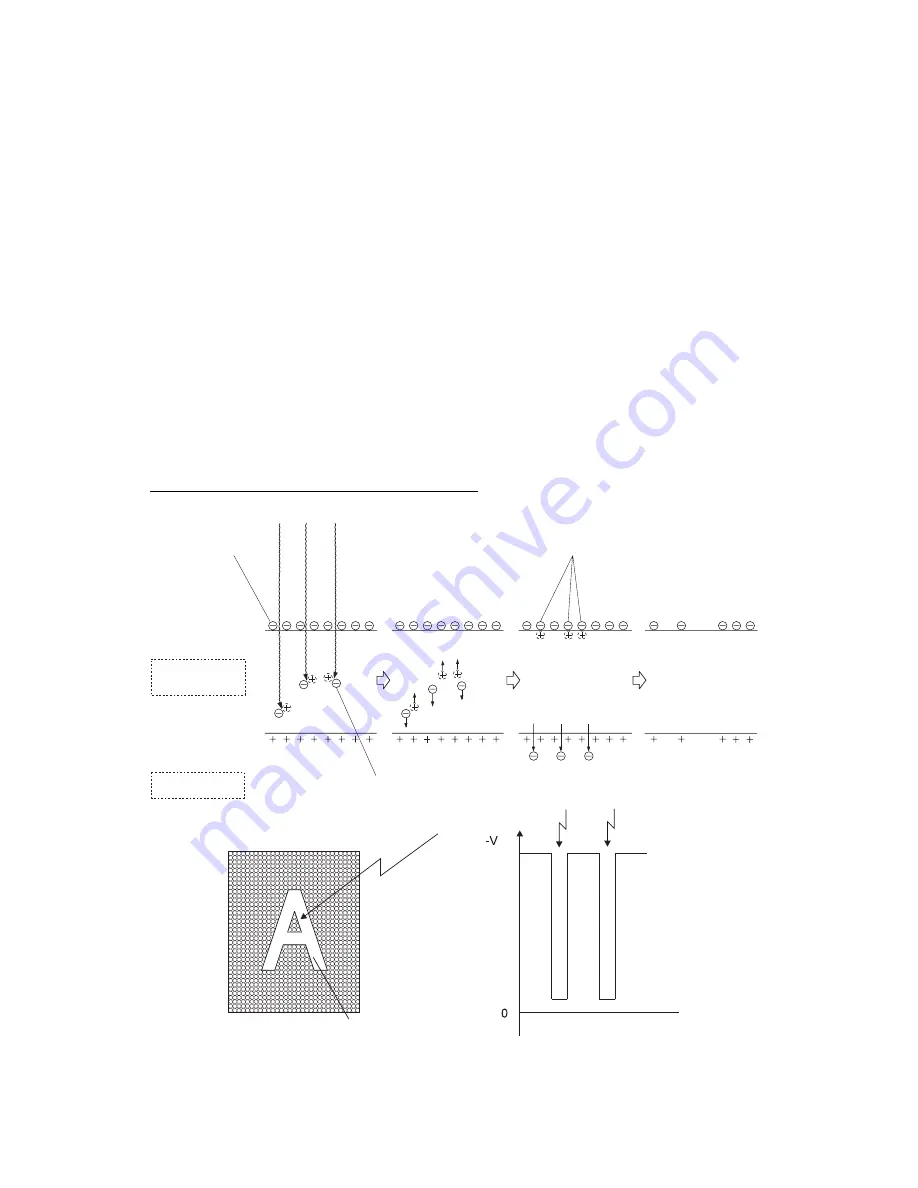

In the exposure step, the surface of the drum negatively charged by the previous

charging step is scanned by a thin laser beam. The light radiated from the laser diode

of the ROS (Raster Output Scanner) scans the drum from one end to the other. The

light passes via a rotating polygon mirror (12 facets) and also via a lens.

The radiation of the laser beam is adjusted according to a video signal from the PWBA

ESS.

The laser beam shot at the drum excites electrons directed to the photoconductor. As

a result, electron hole pairs are induced in the photoconductive layer. Since electrons

are moved toward the body inside the drum by the electric field, the electron-hole pairs

move to the surface of the photoconductive layer. Negative charges in this portion

decrease, thus creating an invisible electrostatic latent image there.

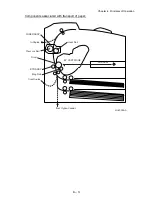

Toner particles are adsorbed onto this electrostatic latent image in the next step. Thus,

the image is developed. The toner particles adsorbed to the drum are attracted to

positive charges supplied by the BTR, and are transferred to the paper. The drum is

sent for peeling and cleaning steps.

Electrostatic latent image formed on drum:

JG6104AA

Summary of Contents for 9045N

Page 1: ...Laser Printer TallyGenicom 9045N Service Manual J20006AA ...

Page 16: ...xv Blank Page ...

Page 20: ...Chapter 1 Troubleshooting Chapter 1 Troubleshooting CONTENTS Blank Page ...

Page 88: ...1 68 Chapter 1 Troubleshooting Blank Page ...

Page 160: ...1 140 Chapter 1 Troubleshooting Blank Page ...

Page 162: ...1 142 Chapter 1 Troubleshooting Blank Page ...

Page 164: ...Chapter 2 Printer Diagnostics Chapter 2 Diagnostics CONTENTS 11 Print Summary 2 16 ...

Page 194: ...1 10 Chapter 3 Removal and Replacement Procedures RRPs RRP2 150 PAPER CASSETTE ...

Page 213: ...1 29 Chapter 3 Removal and Replacement Procedures RRPs RRP3 550 PAPER CASSETTE ...

Page 240: ...1 56 Chapter 3 Removal and Replacement Procedures RRPs RRP4 150 paper Feeder ...

Page 257: ...1 73 Chapter 3 Removal and Replacement Procedures RRPs RRP5 550 Paper Feeder ...

Page 277: ...1 93 Chapter 3 Removal and Replacement Procedures RRPs RRP6 Xerographics ...

Page 302: ...1 118 Chapter 3 Removal and Replacement Procedures RRPs RRP7 500 Paper Exit ...

Page 322: ...1 138 Chapter 3 Removal and Replacement Procedures RRPs RRP8 Frame Drive ...

Page 331: ...1 147 Chapter 3 Removal and Replacement Procedures RRPs RRP9 Electrical ...

Page 394: ...1 210 Chapter 3 Removal and Replacement Procedures RRPs ...

Page 454: ...1 270 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 459: ...4 3 Chapter 4 Plug Jack P J Connector Locations Blank Page ...

Page 465: ...4 9 Chapter 4 Plug Jack P J Connector Locations 3 2 OCT Option P J Diagram ...

Page 468: ...4 12 Chapter 4 Plug Jack P J Connector Locations Blank Page ...

Page 470: ...Chapter 5 Parts Lists Chapter 5 Parts Lists CONTENTS Blank Page ...

Page 479: ...5 9 Chapter 5 Parts List Blank Page ...

Page 483: ...5 13 Chapter 5 Parts List Blank Page ...

Page 490: ...5 20 Chapter 5 Parts List PL 7 2 500 PAPER EXIT 2 2 OPTION FACE UP TRAY ILLUSTRA TION ...

Page 496: ...5 26 Chapter 5 Parts List OPTIONS PL 10 1 OPTION DUPLEX ILLUSTRATION ...

Page 501: ...5 31 Chapter 5 Parts List Blank Page ...

Page 529: ...6 19 Chapter 6 Principles of Operation J26119AA EP CARTRIDGE BTR ASSY ...

Page 531: ...6 21 Chapter 6 Principles of Operation LD Assembly JG6121AA SOS PWB Scanner Assembly ...

Page 535: ...6 25 Chapter 6 Principles of Operation ...

Page 558: ...6 48 Chapter 6 Principles of Operation Blank Page ...

Page 584: ...7 24 Chapter 7 Wiring Diagrams and Signal Information Blank Page ...

Page 608: ...Chapter 9 ESS Options Chapter 9 Controller ESS Options Contents Blank Page ...