6 – 22

Chapter 6 Principles of Operation

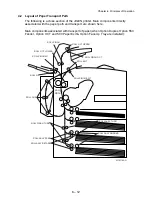

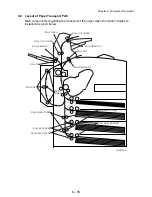

5.4 Fuser

Heat Roll

This is a hollow metal tube having a coated surface. This tube is heated by the

inside Heater Rod. Heat is applied to the paper passing between this roll and the

Pressure Roll. This heat fuses and fixes the toner on the paper.

Pressure Roll

This is a metal shaft coated with sponge rubber. Pressure is applied to the paper

between this roll and the Heat Roll. This pressure presses the melted toner against

the paper.

Heater Assembly

The Heater Assembly consists of a Heater Rod located in a Heat Roll and a

harness connecting the Heater Rod to a terminal. The Heater Rod consists of

heater coil inside a quartz glass and heats up the Heat Roll.

Temperature Sensor

This is a resistor (thermistor) having a known value of resistance that sensitively

varies with temperature. This sensor is mounted in contact with the surface of the

Heat Roll, and monitors the temperature of the surface. The power supply of the

Heater Rod is turned ON and OFF using the signal from this sensor, so that the

surface temperature of the Heat Roll can be maintained within a specified range.

This signal is also used to provide a first stage of overheat protection.

Thermostat Sensor (STS)

Two STS are installed. The STS are connected to the Heat Roll in series.

This provides a second stage of overheat protection. If the first stage does not

prevent the Fuser from overheating, the Thermostat cuts off the power-supply

circuit for the Heater Rod. The STS operates as follows:

(1) If the paper is set incorrectly, the Pressure Roll may melt and adhere. As a countermeasure

against this, the power-supply circuit is cut off to cool down the roll, if the detected temperature

gets higher than a preset temperature.

(2) If the temperatures increase at both sides of the Heat Roll, both ends of the paper may curl.

As a countermeasure against this, the mode is switched to Short lamp lighting to control the tem-

perature rise, if the detected temperature exceeds the preset temperature.

Heat Roll Fingers

These fingers peel off the leading edge of the paper from the Heat Roll to prevent

the paper from getting wound around the Heat Roll.

Heat Roll Diode

The negative charge accumulated on the Heat Roll may deteriorate the toner image

on the paper during fixing. The Heat Roll Diode discharges the charge to the frame

ground.

Exit Sensor

This sensor detects the arrival of the paper at a detection point in the exit area

positioned behind the Fuser. This sensor also detects the discharge of the paper

from this point. When the sensor receives light (i.e., paper is present), /EXIT goes

Low.

Summary of Contents for 9045N

Page 1: ...Laser Printer TallyGenicom 9045N Service Manual J20006AA ...

Page 16: ...xv Blank Page ...

Page 20: ...Chapter 1 Troubleshooting Chapter 1 Troubleshooting CONTENTS Blank Page ...

Page 88: ...1 68 Chapter 1 Troubleshooting Blank Page ...

Page 160: ...1 140 Chapter 1 Troubleshooting Blank Page ...

Page 162: ...1 142 Chapter 1 Troubleshooting Blank Page ...

Page 164: ...Chapter 2 Printer Diagnostics Chapter 2 Diagnostics CONTENTS 11 Print Summary 2 16 ...

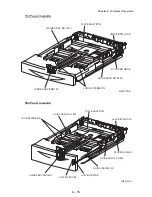

Page 194: ...1 10 Chapter 3 Removal and Replacement Procedures RRPs RRP2 150 PAPER CASSETTE ...

Page 213: ...1 29 Chapter 3 Removal and Replacement Procedures RRPs RRP3 550 PAPER CASSETTE ...

Page 240: ...1 56 Chapter 3 Removal and Replacement Procedures RRPs RRP4 150 paper Feeder ...

Page 257: ...1 73 Chapter 3 Removal and Replacement Procedures RRPs RRP5 550 Paper Feeder ...

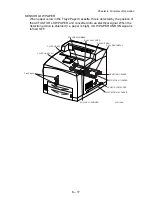

Page 277: ...1 93 Chapter 3 Removal and Replacement Procedures RRPs RRP6 Xerographics ...

Page 302: ...1 118 Chapter 3 Removal and Replacement Procedures RRPs RRP7 500 Paper Exit ...

Page 322: ...1 138 Chapter 3 Removal and Replacement Procedures RRPs RRP8 Frame Drive ...

Page 331: ...1 147 Chapter 3 Removal and Replacement Procedures RRPs RRP9 Electrical ...

Page 394: ...1 210 Chapter 3 Removal and Replacement Procedures RRPs ...

Page 454: ...1 270 Chapter 3 Removal and Replacement Procedures RRPs Blank Page ...

Page 459: ...4 3 Chapter 4 Plug Jack P J Connector Locations Blank Page ...

Page 465: ...4 9 Chapter 4 Plug Jack P J Connector Locations 3 2 OCT Option P J Diagram ...

Page 468: ...4 12 Chapter 4 Plug Jack P J Connector Locations Blank Page ...

Page 470: ...Chapter 5 Parts Lists Chapter 5 Parts Lists CONTENTS Blank Page ...

Page 479: ...5 9 Chapter 5 Parts List Blank Page ...

Page 483: ...5 13 Chapter 5 Parts List Blank Page ...

Page 490: ...5 20 Chapter 5 Parts List PL 7 2 500 PAPER EXIT 2 2 OPTION FACE UP TRAY ILLUSTRA TION ...

Page 496: ...5 26 Chapter 5 Parts List OPTIONS PL 10 1 OPTION DUPLEX ILLUSTRATION ...

Page 501: ...5 31 Chapter 5 Parts List Blank Page ...

Page 529: ...6 19 Chapter 6 Principles of Operation J26119AA EP CARTRIDGE BTR ASSY ...

Page 531: ...6 21 Chapter 6 Principles of Operation LD Assembly JG6121AA SOS PWB Scanner Assembly ...

Page 535: ...6 25 Chapter 6 Principles of Operation ...

Page 558: ...6 48 Chapter 6 Principles of Operation Blank Page ...

Page 584: ...7 24 Chapter 7 Wiring Diagrams and Signal Information Blank Page ...

Page 608: ...Chapter 9 ESS Options Chapter 9 Controller ESS Options Contents Blank Page ...