24

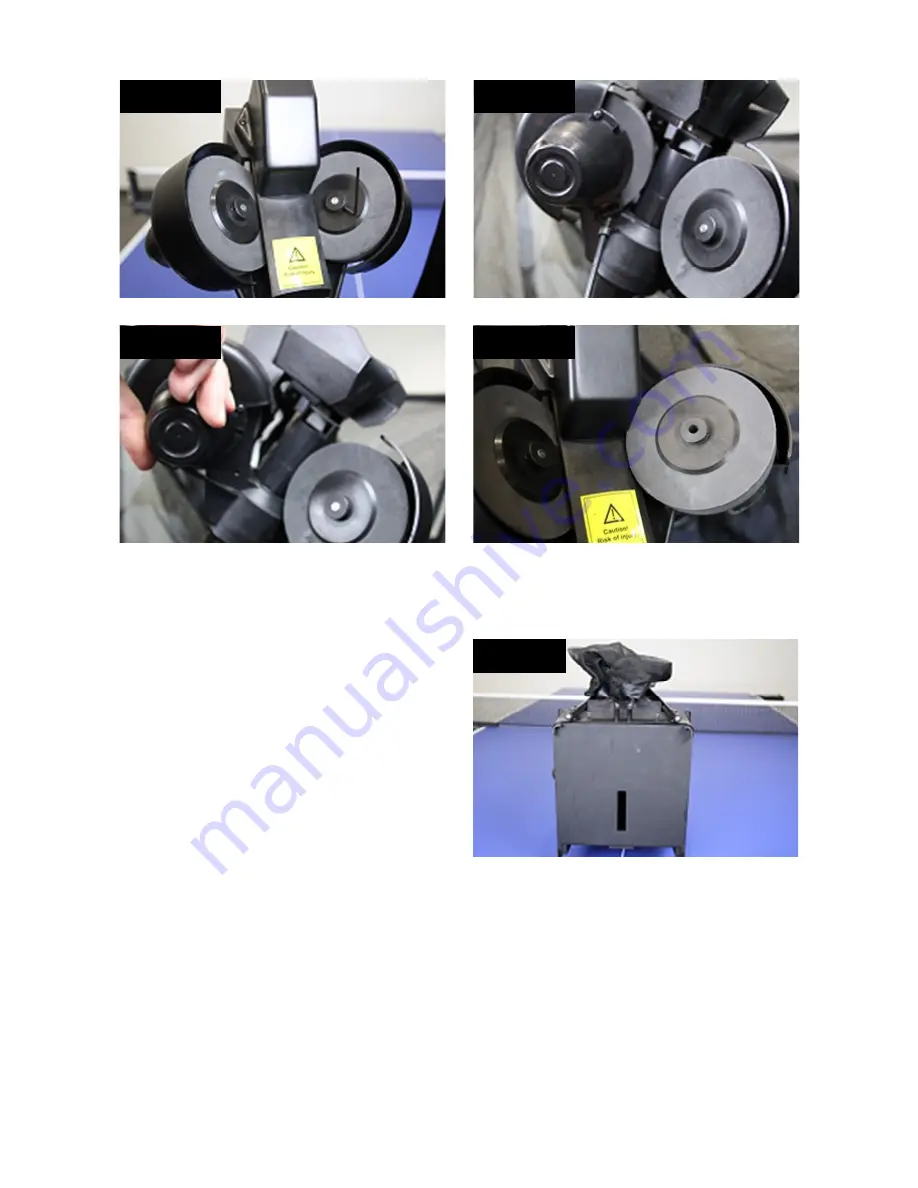

Photo 26A

Photo 26B

Photo 26C

Photo 26D

Ball Jams

Your robot is equipped with a special system

to detect and react to problems in the ball

channel. When the system detects a problem, it

will attempt to automatically clear the ball jam

by turning the Ball Feed Motor and the wheels

forward and backward 7 – 8 times.

If the error can’t be resolved so, all motors stop

and the system shows an error code on the

display (Er1 or Er2). Er1 indicates a problem in the

base of the robot, and Er2 indicates a problem in

the head of the robot (see Troubleshooting, p. 25).

To begin troubleshooting, first disconnect power. For an Er2 code, check that a ball is not stuck among

the 3 wheels (commonly occurs after moving the head height down). If so, simply remove those balls by

hand and resume normal operations.

For an Er1 code, remove the head by disconnecting the Head Cable, loosening the large Black Knob on

the rear of the Ball Tube, and pulling up on the head. Then tilt the entire net system forward to expose

the access slot on the Base Bottom, (see Photo 27). Take a long rod-like tool (screwdriver, dowel, etc.)

that is about 30 cm (12 inches) long, insert it into the access slot, and push balls out the top of the

lower Ball Tube.

Photo 27