©

T.A. Morrison & Co. Inc., 2017

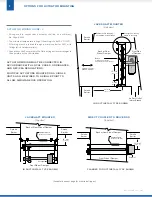

BELIMO FSNF 120

12" max

(305 mm)

Back or Rear

Side of Damper

Front Side

of Damper

24" max

(610 mm)

AIRFLOW

Smoke

Barrier

Sealant or fire stopping,

as required by local codes

Brace

Provided when section

height exceeds 37.5"

(953 mm)

6" max

(152 mm)

See specific mounting

details on next page

Smoke

Barrier

Air Duct Outlet:

Inlet or Branch

Sealant/Caulk

(Around perimeter)

Smoke

Barrier

Smoke

Barrier

24" max

(610 mm)

Back or Rear Side of Damper

Front Side of Damper

Actuator

IN DUCT INSTALL TYPE SHOWN

JACKSHAFT MOUNTED

(side view)

FLANGED TO DUCT INSTALL TYPE SHOWN

DIRECT COUPLED TO DRIVE ROD

(top view)

IN DUCT INSTALL TYPE SHOWN

JACKSHAFT MOUNTED

(top view)

ACTUATOR WIRING MUST BE CONNECTED IN

ACCORDANCE WITH LOCAL CODES, ORDINANCES,

AND NEC/CSA REGULATIONS.

MULTIPLE ACTUATORS MOUNTED ON A SINGLE

UNIT SHALL BE WIRED TO A SINGLE POINT TO

ALLOW SIMULTANEOUS OPERATION.

OPTIONS FOR ACTUATOR MOUNTING

2

ACTUATOR WIRING GUIDE:

&

>

Wiring used to connect each actuator shall be, as a minimum,

No. 16 ga. AWM.

>

The minimum temperature rating of the wiring is to be 302°F

(150°C)

.

>

All wiring must be routed through a metal conduit or EMT, with

fittings (all UL Listed materials).

>

Connections shall occur within the field wiring enclosures integral to

the operators or the UL Listed box.

(See details on next page for other install types.)

Actuator

Smoke

Barrier

Back or Rear Side of Damper

Front Side of Damper

Sealant/Caulk

(Around perimeter)

Smoke

Barrier

24" max

(610 mm)