www.tamcodampers.com

© T.A. Morrison & Co. Inc., 2017

2

6

4

6

1

Back or

Rear Side

of Damper

Front, Label,

Jackshaft,

or Actuator

Side of Damper

2

1

4

3

3

4

3

5

Back or

Rear Side

of Damper

Front, Label,

Jackshaft,

or Actuator

Side of Damper

Front, Label,

Jackshaft,

or Actuator

Side of Damper

Back or Rear

or Wall Side

of Damper

2

7

6

4

1

Opening

8

Smoke

Barrier

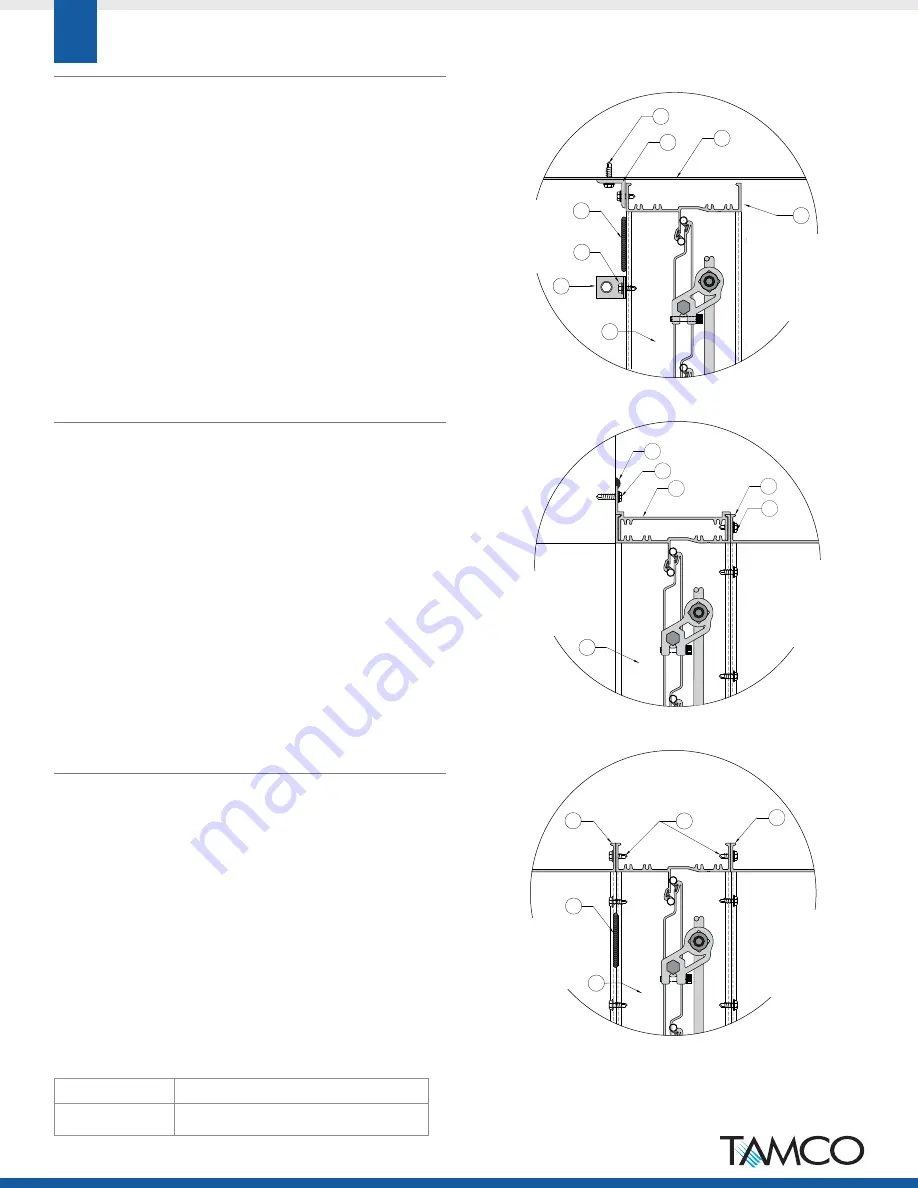

INSTALLATION PROCEDURES FOR |

Smoke Damper Install Types

3

*LEGEND:

1. TAMCO Smoke Damper 4. Fastener

7. Extended flange frame

2. Silicone caulk

5. Sleeve /duct

8. Substrate fastener

3. Clip angle

6. Flanged to Duct connection

*SEE

LEGEND

BELOW

²APPROVED SILICONE CAULK:

Dow Corning:

RTV Silicone Silastic 732, Xiameter 732, Xiameter SLT 5100

Momentive

Performance Materials:

RTV 108

a. Measure and if necessary, adjust the duct or opening to ensure that it

is true and square.

b. Run a bead of silicone caulk² around the inside perimeter of the

flange, where it comes into contact with the damper frame, to

prevent leakage at the connection point between the duct and

damper frame. This step may be performed now or after step "d",

once the smoke damper has been fastened in place.

c. Position the Flanged to Duct mount type smoke damper, so that it is

adjacent to the flanged duct.

d. Secure the flanged connections together using, as a minimum; #8

sms screws,

3

/

16

”

(4.8 mm)

rivets, #12 bolts/nuts, flange mount system,

or tack welds, placed at 12”

(305 mm)

oc intervals. Fasteners should

begin at no more than 6”

(152 mm)

from the corners. A minimum of 1

fastener is required per side.

a. Dampers should be ordered from the factory with extended rear

flanges if they are to be wall mounted.

b. Measure both the wall opening and the damper ID, to ensure that the

two dimensions are identical.

c. Run a bead of silicone caulk² around the perimeter of the damper

flange face, where it will come into contact with the substrate upon

installation. This is to prevent leakage between the damper and the

wall. Caulking may be applied at this step, or following step "e", once

the smoke damper has been fastened in place.

d. Place the damper in the desired location on the wall, so that the

inside of the damper's frame aligns with the edges of the wall

opening.

e. Secure the damper to the wall using, as a minimum; #8 sms screws,

3

/

16

”

(4.8 mm)

rivets, #12 bolts/nuts, ¼"

(6.4 mm)

Tapcons, or tack

welds, placed at 12”

(305 mm)

oc intervals. Fasteners should begin at

no more than 6”

(152 mm)

from the corners. A minimum of 1 fastener

is required per side.

a. Determine the location where the damper is to be installed inside

the duct or sleeve. This location must be within 24"

(609 mm)

of the

smoke barrier.

b. Slide the damper into pre-determined sleeve or duct location. Ensure

that the damper, sleeve, and/or duct are all square and true.

c. Situate the clips around the back or rear perimeter of the damper

frame, at a maximum of 12”

(305 mm)

on center (oc) intervals and so

they begin at no more than 6”

(152 mm)

from the corners. A minimum

of 1 clip is required per side.

d. Fasten clips to the duct first and then to the damper using, as a minimum;

#8 sms screws,

3

/

16

”

(4.8 mm)

rivets, #12 bolts/nuts, or tack welds. Clips

are not required on the front (label) side of the damper.

e. Run a bead of silicone caulk² around the inside perimeter of the back

side of the damper, where it comes into contact with the sleeve or

duct. It is not necessary to caulk around the front (label) side of the

damper. If caulking is applied after installation, it is recommended to

caulk around all clips to minimize leakage.

IN DUCT INSTALL TYPE

&

EXTENDED REAR FLANGE INSTALL TYPE (WALL MOUNT)

&

FLANGED TO DUCT INSTALL TYPE

&