©

T.A. Morrison & Co. Inc., 2017

INSTALLATION PROCEDURES FOR | MULTI-SECTION SMOKE DAMPER ASSEMBLIES

4

INSTRUCTIONS BELOW ARE IN ADDITION TO APPLICABLE INSTALL TYPE INSTALLATION PROCEDURES.

MULTIPLE SECTION SMOKE DAMPER ASSEMBLIES SHOULD BE INSTALLED USING SAME FASTENERS AND

FASTENING PATTERNS AS DESCRIBED IN THE INSTRUCTIONS FOR SINGLE-SECTION SMOKE DAMPERS.

9

/

16

"

(14.3 mm)

±

1

/

8

"

(3.2 mm)

Min. #8 sms Screw

or 3/16" Rivet

2"

(610 mm)

(

±¼"

(6.4 mm)

)

Damper

Frame

Damper

Frame

Joiner

Min. #8

sms Screw, or

3

/

16

”

(4.8 mm)

Rivet

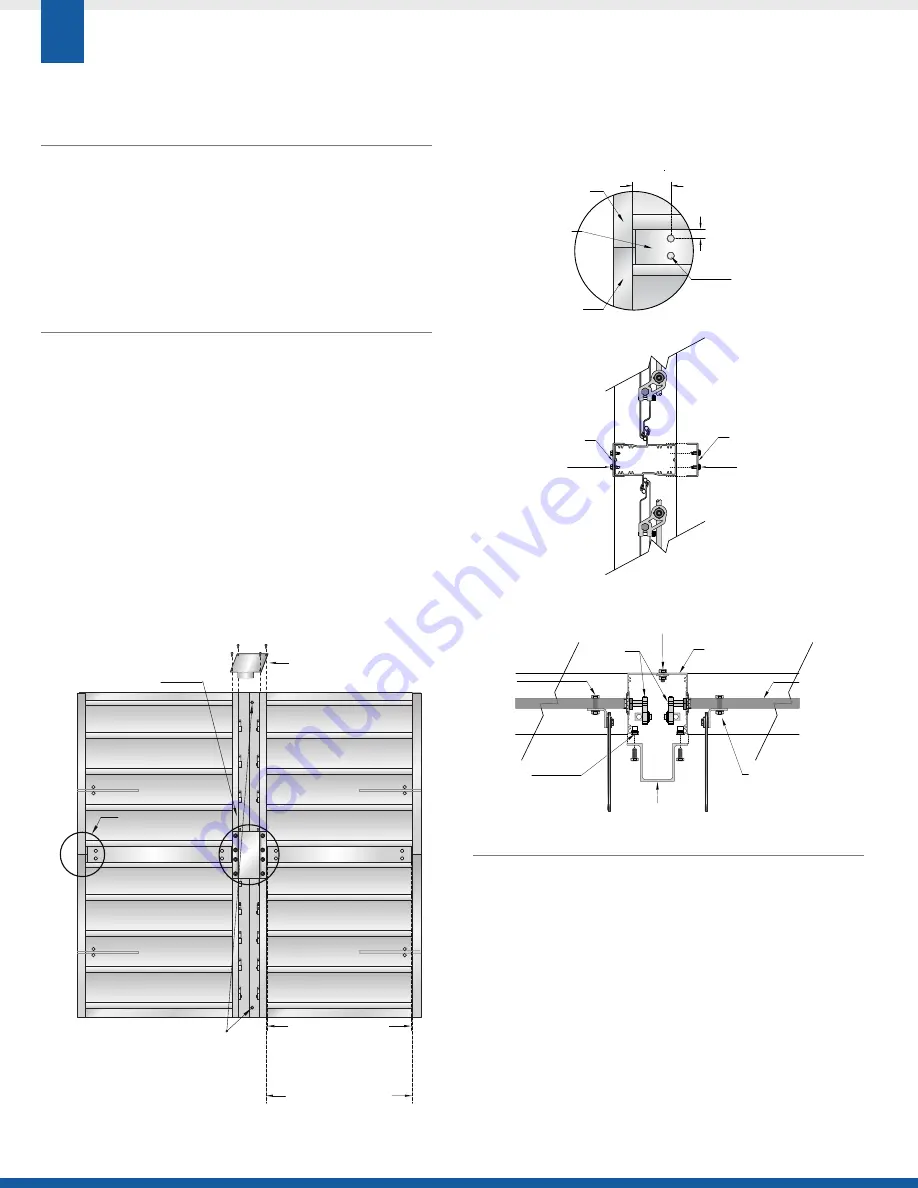

FIG. A

(front view)

Min. ¼”

(6.4 mm)

Bolt/Nut,

#8 sms Screw, or

3

/

16

”

(4.8 mm)

Rivet,

2” (+/- ¼“)

[51 mm (+/- 6 mm)]

from each end of the damper.

Damper

Blade

Damper

Linkage

Damper

Frame

¼"-20

Bolt/Nut

Jackshaft Linkage

(if provided)

Rivet Nuts

(inserted into frame)

Bridge

Min. 14”

(355 mm)

long,

secured with ¼"

(6.4 mm)

bolts

FIG. C

(top view)

ASSEMBLING SMOKE DAMPERS THAT ARE

MULTIPLE SECTIONS HIGH:

a. Slide joiners over frame members, where top and bottom sections

meet.

b. Joiners must be secured to both the front (label) and back (rear) side

of damper assemblies.

c. Attach each joiner to the damper frame members using, as a minimum,

four #8 sms screws or rivets as shown in Figures A & B.

ASSEMBLING SMOKE DAMPERS THAT ARE

MULTIPLE SECTIONS HIGH AND MULTIPLE

SECTIONS WIDE:

a. Slide joiners over frame members, where top and bottom sections

meet.

b. Joiners must be secured to both the front (label) and back (rear) side

of damper assemblies.

c. Attach each joiner to the damper frame members using, as a

minimum, four #8 sms screws or rivets as shown in Figures A & B.

d. Install the bridge bracket connecting the lower sections. Place the

bridge bracket so that it is centered over the joint where all four

damper sections meet.

e. Fasten the Bridge Bracket in place, using ¼"-20 bolts, making sure

they are secured in the pre-set, factory-supplied rivet nut holes.

MULLION END CAPS

FOR FLANGED TO DUCT INSTALL TYPE,

MULTI-SECTION DAMPER INSTALLATIONS

>

Mullion end caps are provided with all multi-section dampers

that are to be installed as Flanged to Duct Install Type.

>

These are required to prevent air flow from passing through

open channels. (Mullion end caps are not intended for use as

structural support.)

>

Caulk surfaces between mullion end caps and damper frame for

an airtight seal.

>

Mullion end caps are not required for In Duct and Extended Rear

Flange Install Type dampers. As such they are not provided as

standard, but are available for order as separate parts.

Joiner

Joiner

Min. #8

sms Screw, or

3

/

16

”

(4.8 mm)

Rivet

Min. #8

sms Screw, or

3

/

16

”

(4.8 mm)

Rivet

FIG. B

(side view)

Joiner

Damper Section ID

Joiner width =

Damper Section ID

Less 0.5”

(12.7 mm)

(± 0.125”

(3 mm)

)

(See Fig. A & B

Details)

Bridge Bracket centered

where sections meet

(See Fig. C Detail)

Frame members are designed

to overlap and are manufactured

with aligned positioning holes.

When dampers are positioned

correctly, holes will be aligned.

Joiner

Mullion End Cap

(at top and bottom)