10

3. Maintenance instructions

10. Install the assembled valve back in it’s place. When assembling the valve, tighten the screws

alternately to even tightness.

Replacing the oil separator cartridge

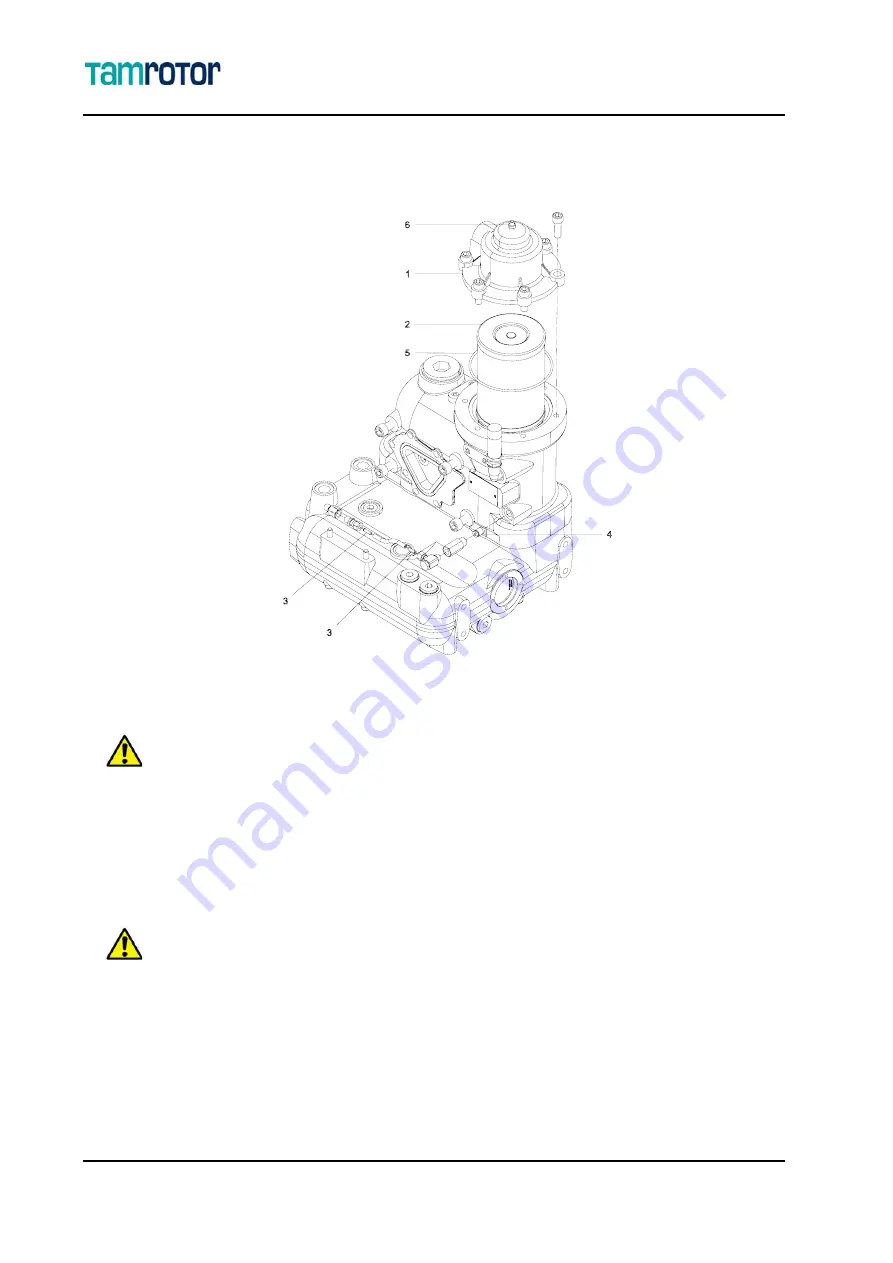

3.7 Testing the pressure relief valve

The opening pressure of the pressure relief valve must be tested in a separate pressurized air line. The

pressure relief valve has been tested at the manufacturer's site before shipping out the compressor. If the

valve has been replaced, it needs to be tested for proper operation. This procedure can be performed only

by a qualified mechanican.

The operation of the valve can be tested by turning the cap (1) counter-clockwise 1 to 2 turns. Always

tighten up the pressure relief valve cap properly to avoid damage caused by vibration.

There should be about 2 mm clearance between the nut (6) and the top of the discharge valve, when there is

no pressure in the receiver or the network. Do not tighten the nut!

All adjustment and repair operations of the pressure relief valve must be performed by qualified

maintenance technicians. All local regulations must be observed.

The compressor must be stopped and secured from automatic restart before attempting this procedure.