English

HELIOS

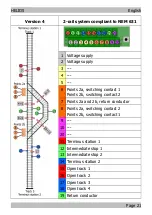

Shuttle operation

The shuttle service is run fully automatically:

After a stop (at a terminus or intermediate stop), HELIOS sets the

points.

HELIOS controls the locomotives´ accelaration depending on the

individual settings.

On open track, HELIOS limits the locomotives´ speed according to

the individually set maximum speed.

As soon as an integrated occupancy sensor detects a locomotive

driving into a section with a station or an intermediate stop, HELIOS

starts braking the locomotive.

HELIOS makes the locomotives stop for the set time at stations or

intermediate stops.

The procedure varies depending on the version, the number of

locomotives on the shuttle line and the starting positions of the

locomotives. Basically the following applies:

When operating 2 locomotives which start from the two tracks of

one terminus, the two locomotives shuttle one after the other

between start and destination station. A possibly existing second

track at the destination station will not be used.

When operating shuttle lines with intermediate stops and at least 2

locomotives starting from the two terminus stations, the first

locomotive reaching the intermediate stop waits for driving on until the

oncoming (second) locomotive has reached the second track of the

intermediate stop. If neccesary, the set hold time will be exceeded.

Further information on operation → section 6.1.

Page 10

Summary of Contents for HELIOS

Page 59: ...HELIOS English Page 59...