3

English

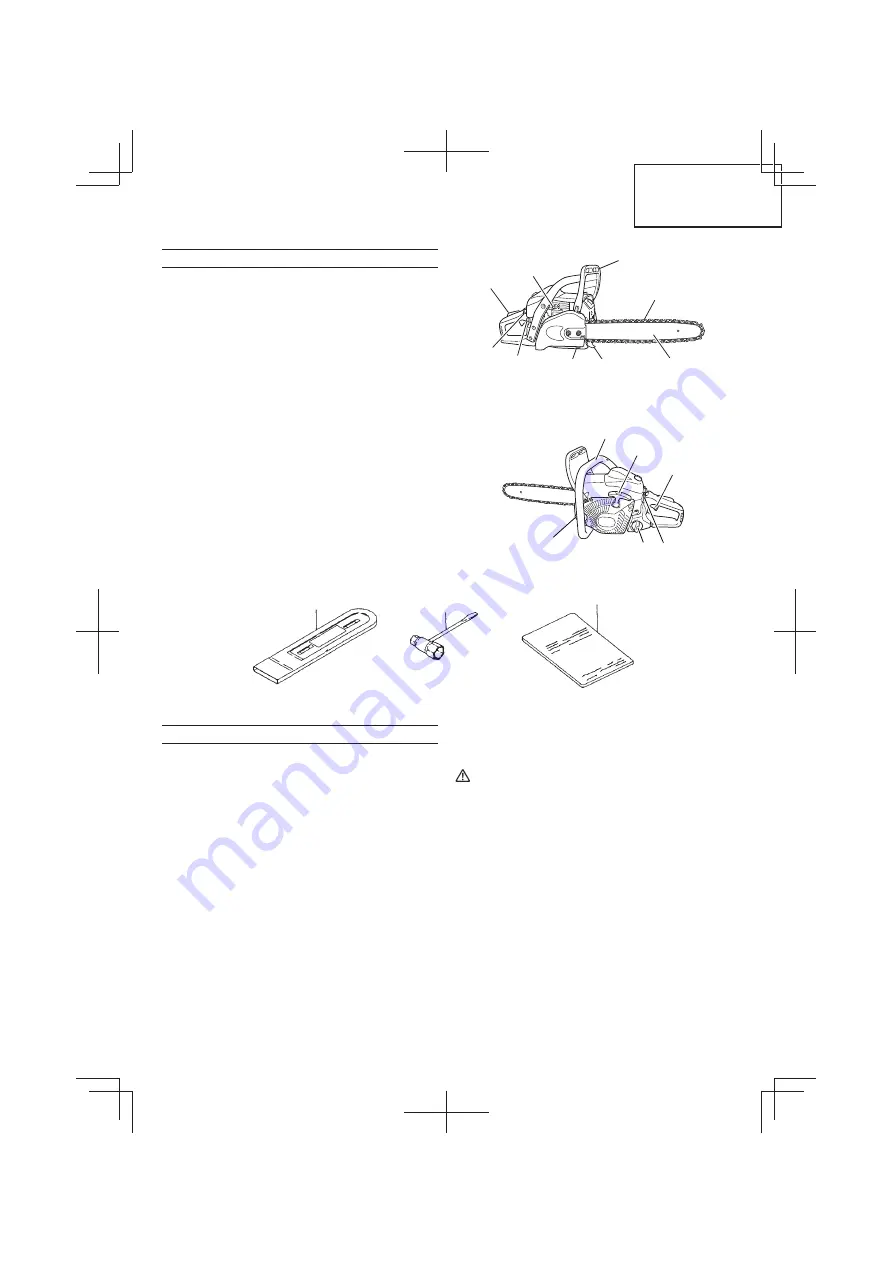

WHAT IS WHAT?

1. Throttle lever: Device activated by the operator

ʼ

s

fi

nger, for

controlling the engine speed.

2. Throttle lever lockout: Device that prevents the accidental

operation of the throttle lever until manually released.

3. Stop switch: Device for allowing the engine to be started or

stopped.

4. Oil tank cap: For closing the oil tank.

5. Recoil starter: Pull handle to start the engine.

6. Front handle: Support handle located at or towards the front of

the engine housing.

7. Fuel tank cap: For closing the fuel tank.

8. Choke lever: Device for enriching the fuel/air mixture in the

carburetor, to aid starting.

9. Priming pump; Device for supplying extra fuel, to aid starting.

10. Decompression valve: Device for reducing the compression

pressure to aid starting.

11. Guide bar: The part that supports and guides the saw chain.

12. Saw chain: Chain, serving as a cutting tool.

13. Chain brake (Front hand guard): Device for stopping or locking

the chain.

14. Spiked bumper: Device for acting as a pivot when in contact with

a tree or log.

15. Chain catcher: Device for restraining the saw chain.

16. Guide bar cover: Device for covering the guide bar and saw

chain when the unit is not being used.

17. Combi box spanner: The tool for removing or installing a spark

plug and tensioning the saw chain.

18. Handling instructions: Included with unit. Read before operation

and keep for future reference to learn proper, safe techniques.

15

16

16

17

17

18

13

12

11

14

8

2

9

15

10

6

5

1

3

7

4

WARNINGS AND SAFETY INSTRUCTIONS

Operator safety

○

Always wear a safety face shield or goggles.

○

Gloves should be used when sharpening chain.

○

Always wear safety protective equipment such as jacket,

trousers, gloves, helmet, boots with steel toe-caps and non-slip

soles, and eye, ear and leg protection equipment whenever you

use a chain saw. For working in trees the safety boots must be

suitable for climbing techniques. Do not wear loose clothing,

jewelry, short pants, sandals or go barefoot.

Secure hair so it is above shoulder length.

○

Do not operate this tool when you are tired, ill or under the

in

fl

uence of alcohol, drugs or medication.

○

Never let a child or inexperienced person operate the machine.

○

Wear hearing protection. Pay attention to your surroundings.

Be aware of any bystanders who may be signaling a problem.

Remove safety equipment immediately upon shutting o

ff

engine.

○

Wear head protection.

○

Never start or run the engine inside a closed room or building.

Breathing exhaust fumes can kill.

○

For respiratory protection, wear a protection mask while emitting

the chain oil mist and dust from sawdust.

○

Keep handles free of oil and fuel.

○

Keep hands away from cutting equipment.

○

Do not grab or hold the unit by the cutting equipment.

○

When the unit turned o

ff

, make sure the cutting attachment has

stopped before the unit is set down.

○

When operation is prolonged, take a break from time to time

so that you may avoid possible Hand-Arm Vibration Syndrome

(HAVS) which is caused by vibration.

○

The operator must obey the local regulations of cutting area.

WARNING

○

Antivibration systems do not guarantee that you will not sustain

Hand-Arm Vibration Syndrome or carpal tunnel syndrome.

Therefore, continual end regular users should monitor closely

the condition of their hands and

fi

ngers. If any of the above

symptoms appear, seek medical advice immediately.

○

Long or continuous exposure to high noise levels may cause

permanent hearing impairment. Always wear approved hearing

protection when operating a unit/machine.

○

If you are using any medical electric/electronic devices such

as a pacemaker, consult your physician as well as the device

manufacturer prior to operating any power equipment.

Unit/machine safety

○

Inspect the entire unit/machine before each use. Replace

damaged parts. Check for fuel leaks and make sure all fasteners

are in place and securely tightened.

○

Replace parts that are cracked, chipped or damaged in any way

before using the unit/machine.

○

Make sure the side case is properly attached.

○

Keep others away when making carburetor adjustments.

○

Use only accessories as recommended for this unit/machine by

the manufacturer.

○

Never let the chain strike any obstacle. If the chain makes

contact, the machine should be stopped and checked carefully.

000Book̲TCS51EA̲Eng.indb 3

000Book̲TCS51EA̲Eng.indb 3

2017/12/18 8:49:14

2017/12/18 8:49:14