Tanco Autowrap -

VariAuto

Operator’s Manual

12

6. MACHINE SETUP

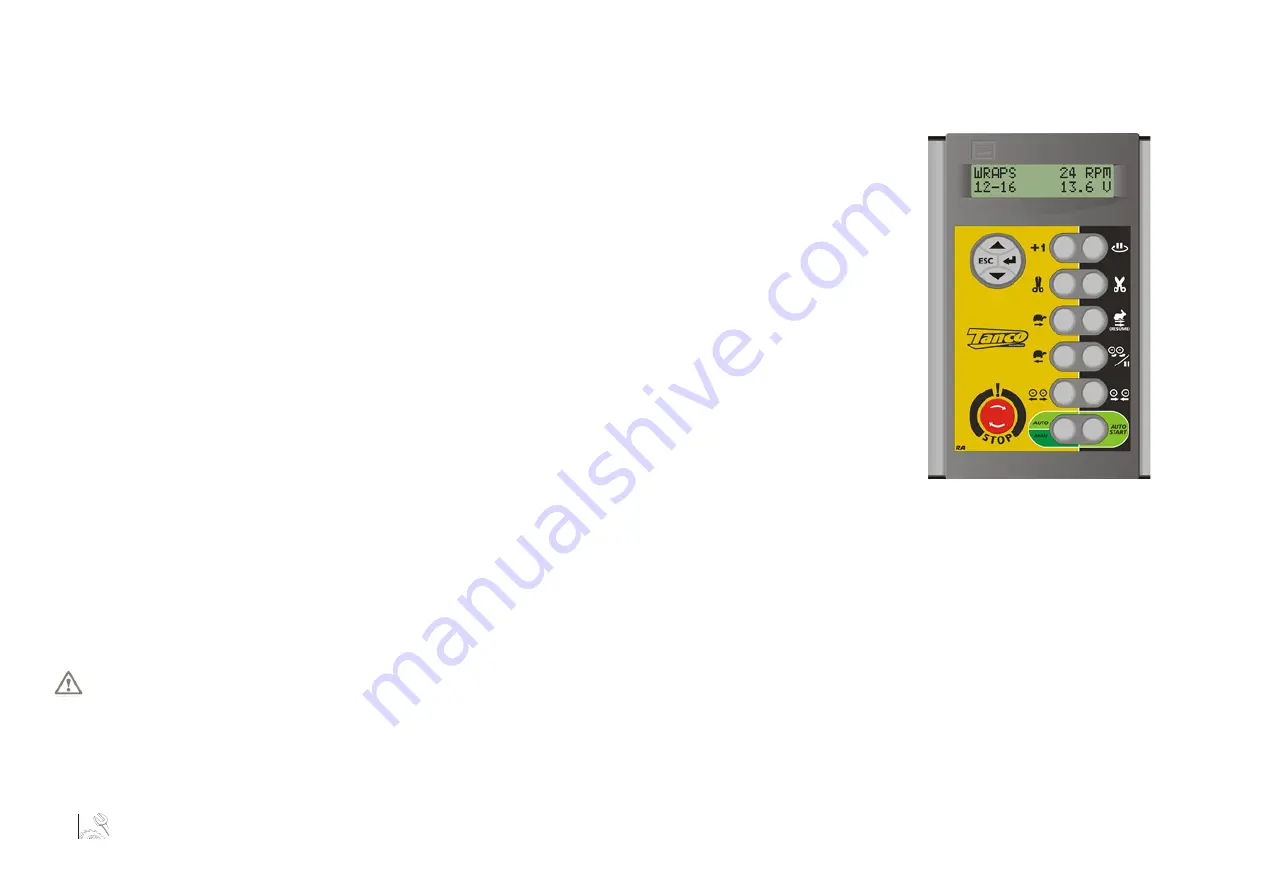

VariAuto Control Box

6.2. Expert Control Unit

The EH control units consist of the emergency stop button, a control cable, a fuse and a battery cable. The control unit should be

attached to a suitable place in the tractor cab using the suction pad provided.

The Remote Control Unit is not Shock Proof, make sure that is fastened to a soft pad that secures a non-vibratting foundation.

Electrical Connection

The electric supply for the machine’s remote control and electro-hydraulic components must come directly from the tractors’

12 volt battery.

The electric wires from the battery must have an area measurement of min. 2,5 mm2. Connection to other contacts on the tractor

can cause risk of malfunction and is not recommended.

Note:

Brown leader goes to the Battery’s Possitive Pole

Blue leader goes to the Battery’s Negative Pole

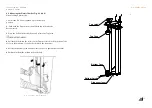

6.3. VariAuto Hydraulic Connection

The hydraulic hoses between machine and tractor are equipped with 1/2” ISO Male Quick-Couplers. Ensure the oil pressure has been

discharged before you connect the oil hoses using the tractor’s hydraulic lever.

To make sure that the bale wrapper works properly, the tractors’ oil pressure has to be at least 180 bar. The oil flow should be 15 - 25 liters per minute. The return pressure on the return

must be as low as possible, and not exceed 10 bar. This should be measured with a gauge. It is recommended to use one single-working hydraulic outlet and arrange a free return circuit

to the oil tank.

If you are unsure of what oil pressure the tractor gives, or what oil pressure the bale wrapper receives, please contact your machinery dealer. Generally all tractors have got some counter-

pressure in their hydraulic return systems. Some tractors have more than others.

Note:

The Hose with the Red Cap shall be connected to pressure ‘P’ and Hose with Blue Cap to the return ‘T’.

The Hydraulic free return is important to ensure that the parking brake on the wrapping arms is not released during transport by pressure building up in the return line.

When the return coupling is connected to a free return this pressure is released. If it is connected through the tractor spool valve the oil cannot escape.

Summary of Contents for S200 VariAuto

Page 1: ...S200 VariAuto S200 VA V 01 18 ENG_002 Innovation in Agricultural Machinery Operator s Handbook...

Page 45: ...3 Tanco Autowrap S200 VA Spare Parts Manual 1 Chassis Assembly...

Page 54: ...Tanco Autowrap S200 VA Spare Parts Manual 12 1 5 Load Arm Assembly LHS...

Page 56: ...Tanco Autowrap S200 VA Spare Parts Manual 14 1 6 Load Arm Assembly RHS...

Page 58: ...Tanco Autowrap S200 VA Spare Parts Manual 16...

Page 59: ...17 Tanco Autowrap S200 VA Spare Parts Manual 2 Cut Start...

Page 62: ...Tanco Autowrap S200 VA Spare Parts Manual 20...

Page 63: ...21 Tanco Autowrap S200 VA Spare Parts Manual 3 Wrap Arm Drive...

Page 66: ...Tanco Autowrap S200 VA Spare Parts Manual 24...

Page 67: ...25 Tanco Autowrap S200 VA Spare Parts Manual 4 Wrapping Arms...

Page 68: ...Tanco Autowrap S200 VA Spare Parts Manual 26 4 1 Wrap Arm Assembly...

Page 72: ...Tanco Autowrap S200 VA Spare Parts Manual 30...

Page 73: ...31 Tanco Autowrap S200 VA Spare Parts Manual 5 Dispenser Assembly...

Page 78: ...Tanco Autowrap S200 VA Spare Parts Manual 36...

Page 79: ...37 Tanco Autowrap S200 VA Spare Parts Manual 6 Expert Controller...

Page 80: ...Tanco Autowrap S200 VA Spare Parts Manual 38 6 1 Expert Controller 1 2 1a 1b...

Page 82: ...Tanco Autowrap S200 VA Spare Parts Manual 40...

Page 83: ...41 Tanco Autowrap S200 VA Spare Parts Manual 7 Hydraulic Valve Assemblies...

Page 86: ...Tanco Autowrap S200 VA Spare Parts Manual 44 1 2 3 4 5 5 6 7 2 Tower Block...

Page 88: ...Tanco Autowrap S200 VA Spare Parts Manual 46 1 2 3 2 2 4 5 6 7 3 Rollers Block...

Page 90: ...Tanco Autowrap S200 VA Spare Parts Manual 48 1 2 3 4 7 4 Oil Filter...