Tanco Autowrap -

VariAuto

Operator’s Manual

41

14. DECLARATION OF CONFORMITY

13. EC DECLARATION OF CONFORMITY

ACCORDING TO DIRECTIVES 2006/42/EC

Manufacturer:

Tanco Autowrap Ltd

Bagenalstown

Co. Carlow

IRELAND

CERTIFIES THAT THE FOLLOWING PRODUCT:

TANCO AUTOWRAP

MODEL: S200 VariAuto

SERIAL NO:

To which this declaration relates, corresponds to the essential requirements of the Directive 2006/42/EC.

To conform to these essential health and safety requirements, the provisions of the following harmonized standards were particularly considered:

ISO 12100, EN 294, prEN 703, EN ISO 13857, EN ISO 4254 - 1, prEN 982.

DATE: 01/10/2017

Signed:

Con Hourihane, Technical Manager

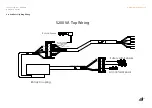

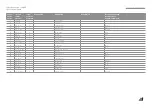

Summary of Contents for S200 VariAuto

Page 1: ...S200 VariAuto S200 VA V 01 18 ENG_002 Innovation in Agricultural Machinery Operator s Handbook...

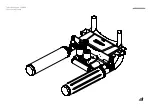

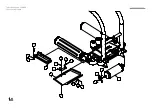

Page 45: ...3 Tanco Autowrap S200 VA Spare Parts Manual 1 Chassis Assembly...

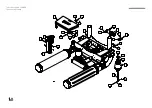

Page 54: ...Tanco Autowrap S200 VA Spare Parts Manual 12 1 5 Load Arm Assembly LHS...

Page 56: ...Tanco Autowrap S200 VA Spare Parts Manual 14 1 6 Load Arm Assembly RHS...

Page 58: ...Tanco Autowrap S200 VA Spare Parts Manual 16...

Page 59: ...17 Tanco Autowrap S200 VA Spare Parts Manual 2 Cut Start...

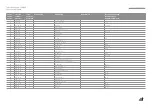

Page 62: ...Tanco Autowrap S200 VA Spare Parts Manual 20...

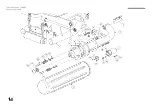

Page 63: ...21 Tanco Autowrap S200 VA Spare Parts Manual 3 Wrap Arm Drive...

Page 66: ...Tanco Autowrap S200 VA Spare Parts Manual 24...

Page 67: ...25 Tanco Autowrap S200 VA Spare Parts Manual 4 Wrapping Arms...

Page 68: ...Tanco Autowrap S200 VA Spare Parts Manual 26 4 1 Wrap Arm Assembly...

Page 72: ...Tanco Autowrap S200 VA Spare Parts Manual 30...

Page 73: ...31 Tanco Autowrap S200 VA Spare Parts Manual 5 Dispenser Assembly...

Page 78: ...Tanco Autowrap S200 VA Spare Parts Manual 36...

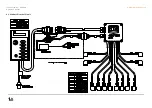

Page 79: ...37 Tanco Autowrap S200 VA Spare Parts Manual 6 Expert Controller...

Page 80: ...Tanco Autowrap S200 VA Spare Parts Manual 38 6 1 Expert Controller 1 2 1a 1b...

Page 82: ...Tanco Autowrap S200 VA Spare Parts Manual 40...

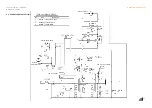

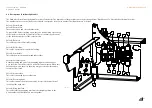

Page 83: ...41 Tanco Autowrap S200 VA Spare Parts Manual 7 Hydraulic Valve Assemblies...

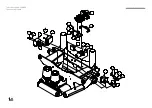

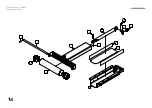

Page 86: ...Tanco Autowrap S200 VA Spare Parts Manual 44 1 2 3 4 5 5 6 7 2 Tower Block...

Page 88: ...Tanco Autowrap S200 VA Spare Parts Manual 46 1 2 3 2 2 4 5 6 7 3 Rollers Block...

Page 90: ...Tanco Autowrap S200 VA Spare Parts Manual 48 1 2 3 4 7 4 Oil Filter...