page 16 TC42_B2

230905-36

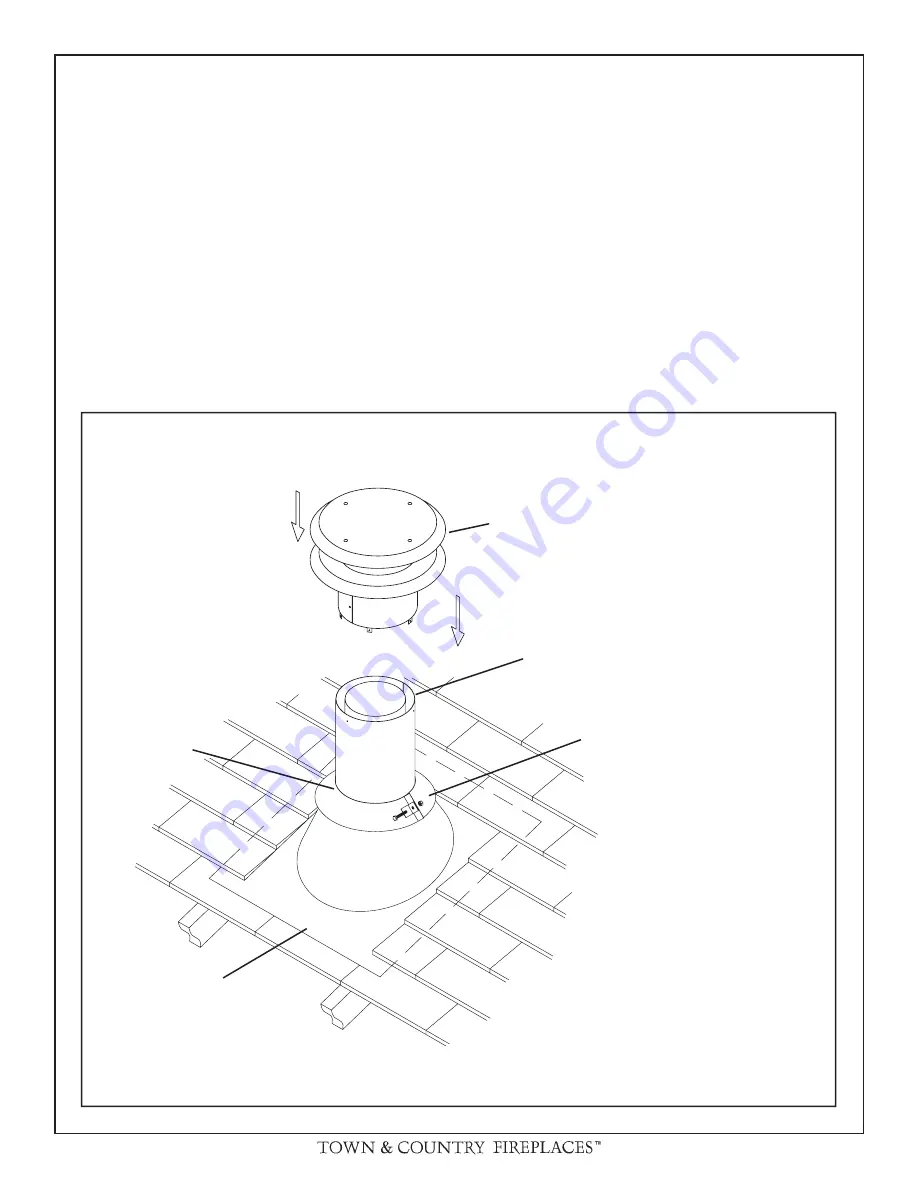

Fig. # 21

VERTICAL TERMINATION CAP

(TCVT.9365)

FLASHING

STORM COLLAR

(TC42.90665)

MASTIC

Note: Adjustable for various

roof pitches, from fl at roof to

12/12 pitch roof.

VENT PIPE

Roof vent terminal:

1) Place the roof fl ashing over top of the vent pipe and nail

securely to the roof using roofi ng nails, top and sides

U

N

DER shingles, lower end OVER shingles to provide

a watershed. Make weather tight by sealing with roofi ng

compound (see Fig. #21).

2) Place the storm collar down over the vent pipe until it

is level. Tighten storm collar for a snug fi t. Apply a thick

horizontal ring of mastic around the pipe at top of storm

collar (see Fig. #21).

3) Lower the roof vent terminal cap over the vent pipe and

secure in place with screws provided (see Fig. #21). Seal

screw heads and joint with caulking to prevent any moisture

entering the venting system.