OPERATING MANUAL

PLASMA CUTTING

GB

Inglese

GB

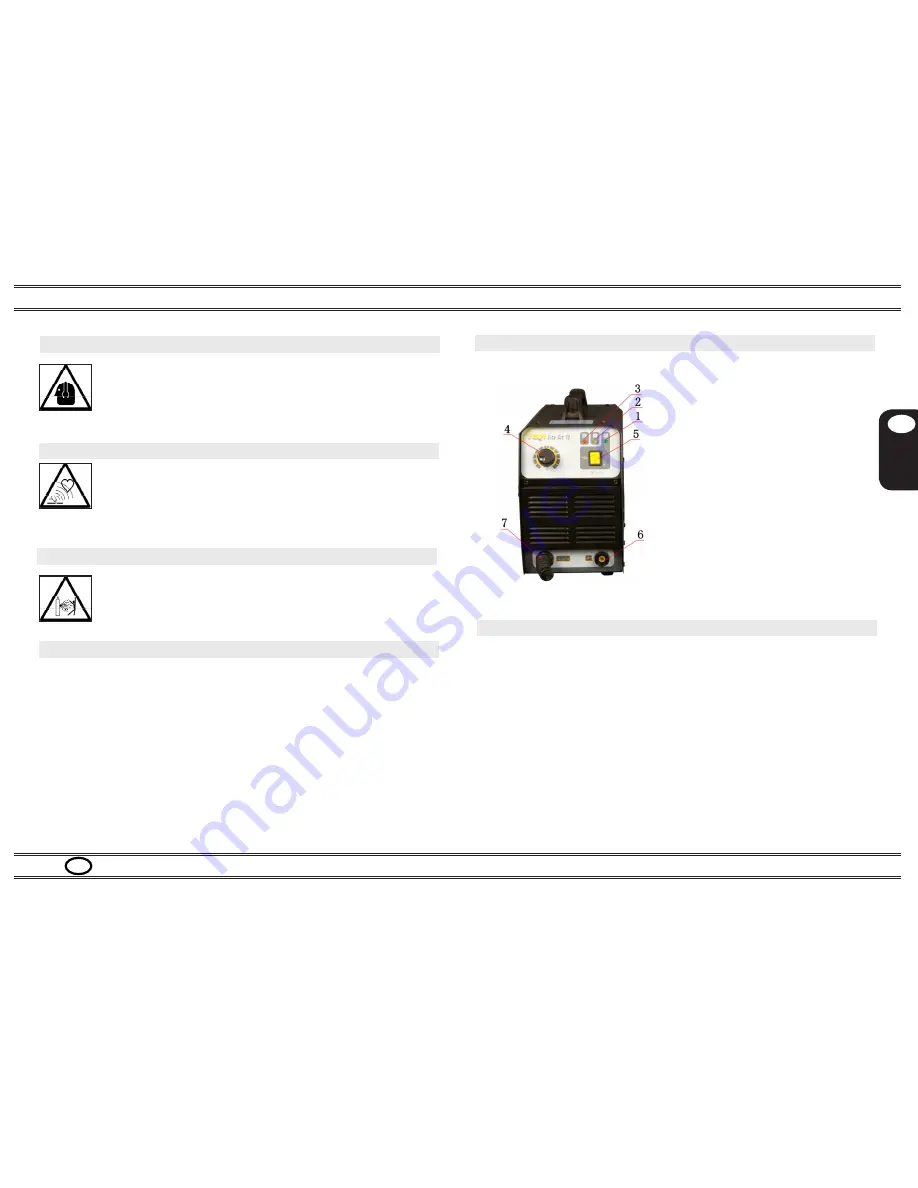

Picture 3 : Site Cut 10 front and

rear view

Figure 3

3.1 3.1

Description of devices on the machine

Site Cut 10 power source

3.2 Safety devices

This system comes equipped with the following safety devices: (see table 1 )

Overload cutout:To avoid overload while cutting

* In the event of the machine termpretrue too high.

* In the event of torch maintenance with main power on. In this event all cutting

function are prevent

HG

•

•

NOISE

This machine does not directly produce noise exceeding 80dB. The

plasma cutting/welding procedure may produce noise levels beyond

said limit; users must therefore implement all precautions required by

law.

PACEMAKERS

The magnetic fields created by high currents may affect the operation

of pacemakers. Wearers of vital electronic equipment (pacemakers)

should consult their physician before beginning any arc welding, cut-

ting, gouging or spot welding operations.

Do not weld in the vicinity of containers under pressure, or in the pre-

sence of explosive dust, gases or fumes. All cylinders and pressure

regulators used in welding operation should be handled with care.

3. General description

This machine is a constant direct current power source, designed for cutting

electrically conductive materials (metals and alloys) using the plasma arc procedu-

re. The plasma gas may be compressed air or nitrogen.

PAGE 3

1. Power indicator

2. OK indicator

3. Over-heat protect indicator

4. Current adjustment knob

5. Power switch

6. Positive output terminal

7. Negative output terminal

Electrical:

EXPLOSIONS