W W W . T A N N E N - P A R A D I E S . D E

- 8 -

Maint storage

Before carrying out maintenance and repair works, always disconnect the machine from

the mains.

1) Maintenance after about 50 drilling passages

Remove the chips from the machine in order not to interfere with the ventilation of

the motor. Check the grill and the drill chuck for tightness. Always tighten up all

screws with the Allen keys.

2) Maintenance after about 10 hours:

In addition to 1):

2.1) if needed, remove resin from the drill and sharpen it.

2.2) clean the guide bars with a cloth.

3) Maintenance after about 250 hours:

In addition to 1) and 2):

3.1) Blow air vents, check the tightness of all screws. Check the tightness of

the gear head. Carbon brushes are designed to work for about 300 hours,

and can be replaced.

4) After the season, it would be good practice to clean the unit, lubricate all moving

parts and keep the drilling machine in a dry place.

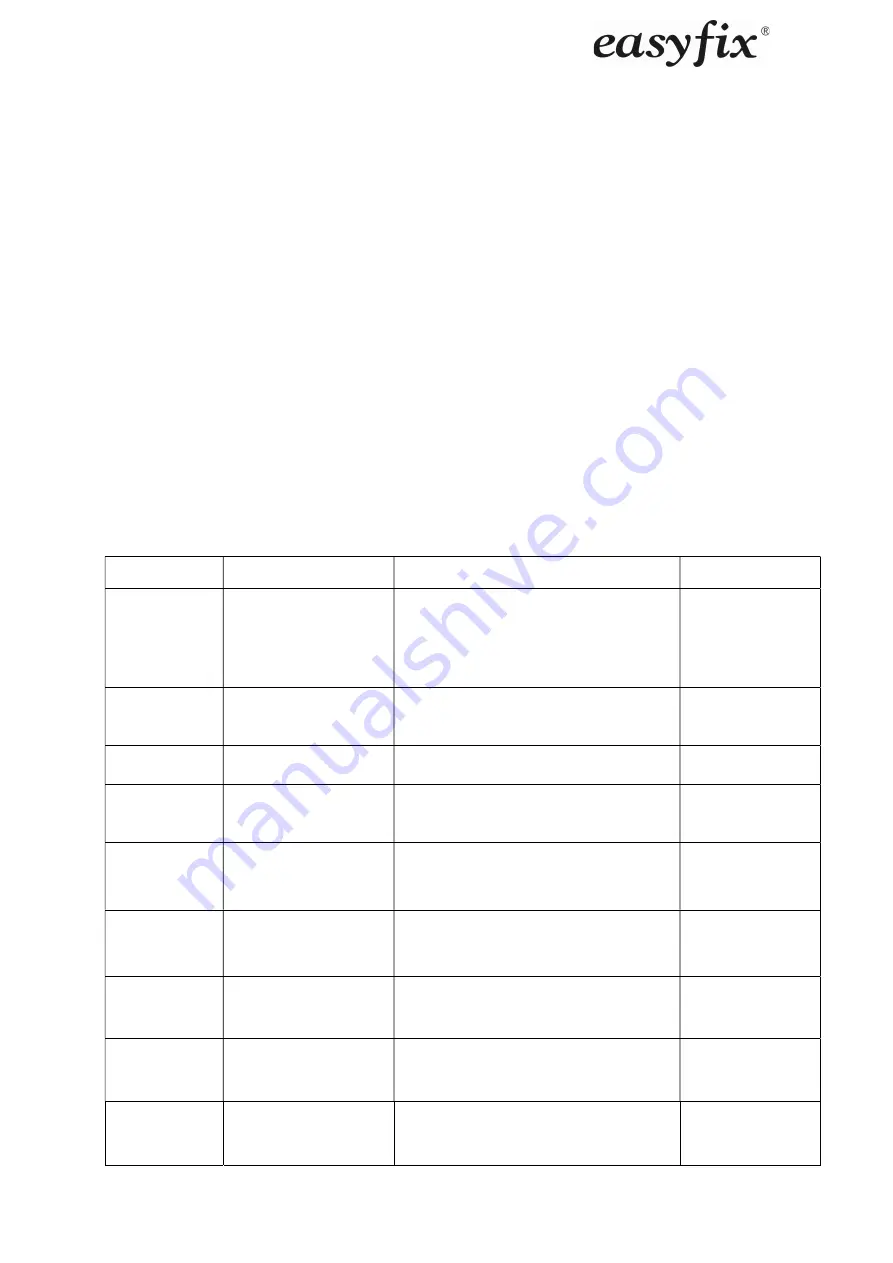

Faults and troubleshooting

Problem

Cause

Removal

Caution

Drill stuck firmly Too fast drilling with too

much pressure.

or:

Too slender tip of the

drill.

(resharpen)

Disconnect the power, raise the tree with

the pedal, then firmly pull the pedal up.

Hold the tree vertically above the drill bit.

Side

planning

or/and rotation can

damage the drilll!

The

machine

does not start

Power

Check the cable connection and power.

While

checking,

disconnect the unit

from the mains!

Drilled hole is

not straight

Centering device is not

set properly

Centering device at a height below the top

level.

Centering

device

is

skewed

Get the centering slide all the way down,

remove the horizontal and vertical

irregularities.

Drilled hole is

too deep

Drill bit is not embedded

deeply enough in the

chuck

Remove the drill bit. Clean of chips, net

and dirt.

While checking,

disconnect the unit

from the mains!

Drilled hole is

too big

Plays on the drill or head Tighten the screws on the chuck and

tighten the chuck.

While checking,

disconnect the unit

from the mains!

Drilled hole is

not deep enough

drill shavings stuck or

residual net

Inspect the drill. Remove the chips and

residual net, clean the drill.

While checking,

disconnect the unit

from the mains!

Bad

drilling

output

blunt drill

Replace or sharpen drill and/or clean the

drill.

While checking,

disconnect the unit

from the mains!

The drill remains

up

Guide bars dirty

Clean and dry with a cloth. If the operation

is not smooth enough lubricate with engine

oil.

While checking,

disconnect the unit

from the mains!