2

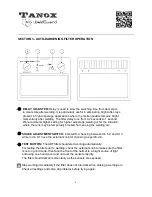

SECTION 1 - SAFETY WARNINGS

–

READ BEFORE USING

ARC RAY

FROM WELDING CAN BURN EYES AND SKIN.

A damaged helmet or

auto-darkening filter (ADF) can reduce the protection against harmful rays (intense visible light,

ultraviolet and infrared) and result in serious injury.

•

Before welding, always inspect the complete helmet and the filter to ensure that they are

not damaged. Also check and select the right shade and other filter settings.

•

Check both the front and back cover lens to see whether they are clean, clear,

undamaged and securely attached to the helmet and cover the auto-darkening filter.

They are for the protection of the ADF. Never weld without the cover lenses on.

•

Replace any worn or damaged parts immediately.

•

Damages to ADF caused by abuse such as excessive temperatures, cracks from impact,

and pitting from spatter caused by poor maintenance will void warranty.

WELDING HELMETS DO NOT PROVIDE UNLIMITED EYE, EAR AND FACE

PROTECTION.

•

Wear impact resistant safety spectacles or goggles and ear protection at all time when

using this helmet.

•

Do not use this helmet for “overhead” welding, laser welding or laser cutting.

•

Do not use the helmet when working with or around explosives or corrosive liquids.

WELDIND ALSO PRODUCES SOME OTHER HAZARDS SUCH AS FUME,

NOISE, SPARK, AND SPATTER

.

Other safety precautions are also needed.

•

Wear protective clothing and footwear made from durable and flame-resistant materials.

•

Provide adequate ventilation and breathing protection against welding fumes.

•

Use protective screens or barriers to protect others from flash and glare.

•

Warn others not to watch the arc.

Summary of Contents for WeldGuard ADF-206S

Page 1: ...Auto Darkening Helmet User s Manual ADF 206S ...

Page 16: ...15 NOTES ...