P R O 1 9 a n d P R O 1 4 B r a k e s

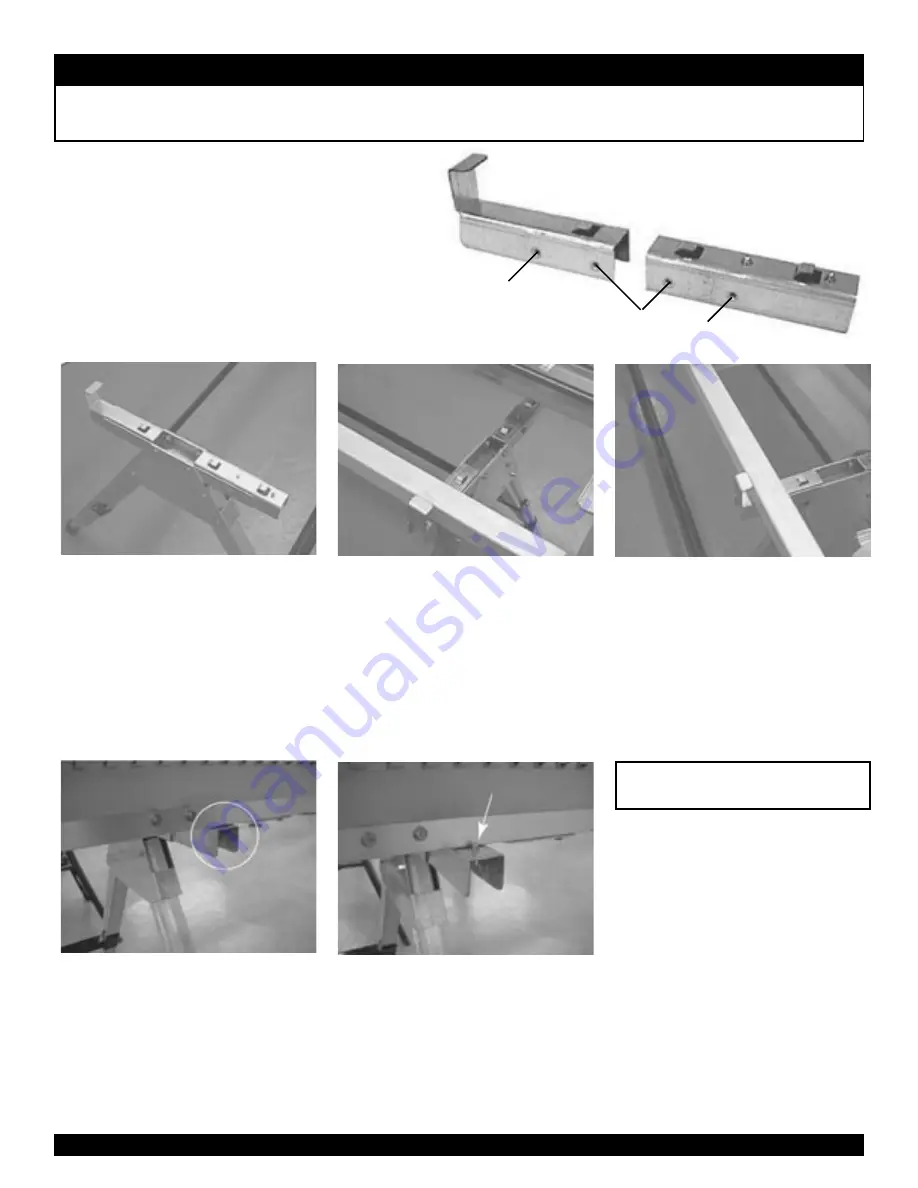

STEP 1

Using the 1/4-20 bolts and lock

washers provided, fasten the brake

mounts to the Leg Set. Depending

on which brake you’re using,

choose the correct holes as shown

in the figure at right.

STEP 2

The snap buttons will be towards

the working side of the brake.

Repeat Step 1 for the other Leg

Set. Be sure both ends of the Snap

Stand are going the same direction

(with the snap buttons on the same

side). See Figure 2 above.

snap buttons are

toward working

side of brake

STEP 3

Place the brake on the assembled

Snap Stand with the Back Rail of

the brake clearing the adaptor

hook as shown in Figures 3A and

3B above.

Back Rail clearing

adaptor hook

The snap button will be covered

by the fixed hinge of the brake as

in Figure 3C above.

STEP 4

Push the brake firmly rearward

into the adaptor hooks. The snap

buttons by the front clips will pop

up and secure the brake on the

Snap Stand. See Figure 4 above.

The brake is now ready for use.

Button pops up when brake is

fully seated

1. Removing the brake from

the Snap Stand is essentially

the opposite of attaching it to

the stand.

2. Lifting the Moving Hinge,

depress the snap button and pull

the brake forward far enough to

hold each snap button down.

3. Be sure the box rail is out of

the Rear Clip. The brake can

now be removed from the stand.

4. Reverse Steps 2 and 1

to disassemble the stand

for transport.

Figure 2

Figure 4

Figure 3A

Figure 3B

Figure 3C

Removing the Brake:

PRO 14

PRO 19 & MAX-

I-MUM II

PRO 14

Installing Brake on Snap Stand

6