3

10/2015 EN

Practical Notes

Operation mode

With the potentiometer on the front plate the operartion mode can be

adjustet. The adjustment must be required before energizied. Adjustment

during energization is not allowed.

Only an automatic start at safety function two-hand control (3) is possible.

Start

Fkt. 1

Fkt. 2

1

MANUAL

MANUAL

2

MANUAL

AUTO

3

AUTO

HAND

4

AUTO

AUTO

5

MANUAL with common

button

Line fault detection e.g. monitoring of ON-button

If the On-button pressed more than 3 s the adequate output contacts of the

safety function can't be switch. The output contacts can be energized when

the On-button pressed again (0.1 s < t

ON

< 3 s).

A line fault is detected if the On-button more than 10 s is actuated. The

output contacts of the adeauate safety function can only be energized with

a reset or re-start with on an off switching of power supply.

ATTENTION - AUTOMATIC START!

According to IEC/EN 60 204-1 part 9.2.5.4.2 and 10.8.3 it is

not allowed to restart automatically after emergency stop.

Therefore the machine control has to disable the automatic

start after emergency stop.

Reset and external failures:

The reset input is used to reset external failures (application failures or

removable external failures as e.g. a line fault on reset button). If the reset

signal is connected to the input for more than 3 sec the unit unit makes a

reset. A new reset is only possible when the reset signal had been switched

off temporarily.

If an external failure occurs because both input channels of a safety function

did not switch on or off within the simultanious time, a reset is only possible

if both channels are switched to off state after removing failure cause.

If an external failure occurs in only one safety function, only this function

will be disconnected. The second safety function still continuous to work.

Function setting

The variants with selectable safety functions have 2 potentiometers Fkt.1

and Fkt.2 to select the required function. The following functions are possible:

Fct. 1 / Fct. 2

Safety function

1

E-Stop

cross fault detection

2

Safety gate

3

Two-hand control

4

Safety mat / Safety edge

5

Exclusive or contacts

6

E-Stop

without

cross fault detection

7

Safety gate

8

Light curtain

Indicators

green LED ON:

on, when supply connected

red LED ERR:

on, at internal error

flashes at external error

green LED K1/K2:

on, when relay K1 and K2 energized

(safety function 1)

flashes at external errors of

safety function 1

green LED K3/K4:

on, when relay K3 and K4 energized

(safety function 2)

flashes at external errors of

safety function 2

Operating Potentiometer

Poti "Start"

Adjustment of operating mode

Manual- or auto start for Fkt.1 and Fkt. 2.

Poti "Fkt.1"

Adjustment of safety function 1

Poti "Fkt.2"

Adjustment of safety function 2

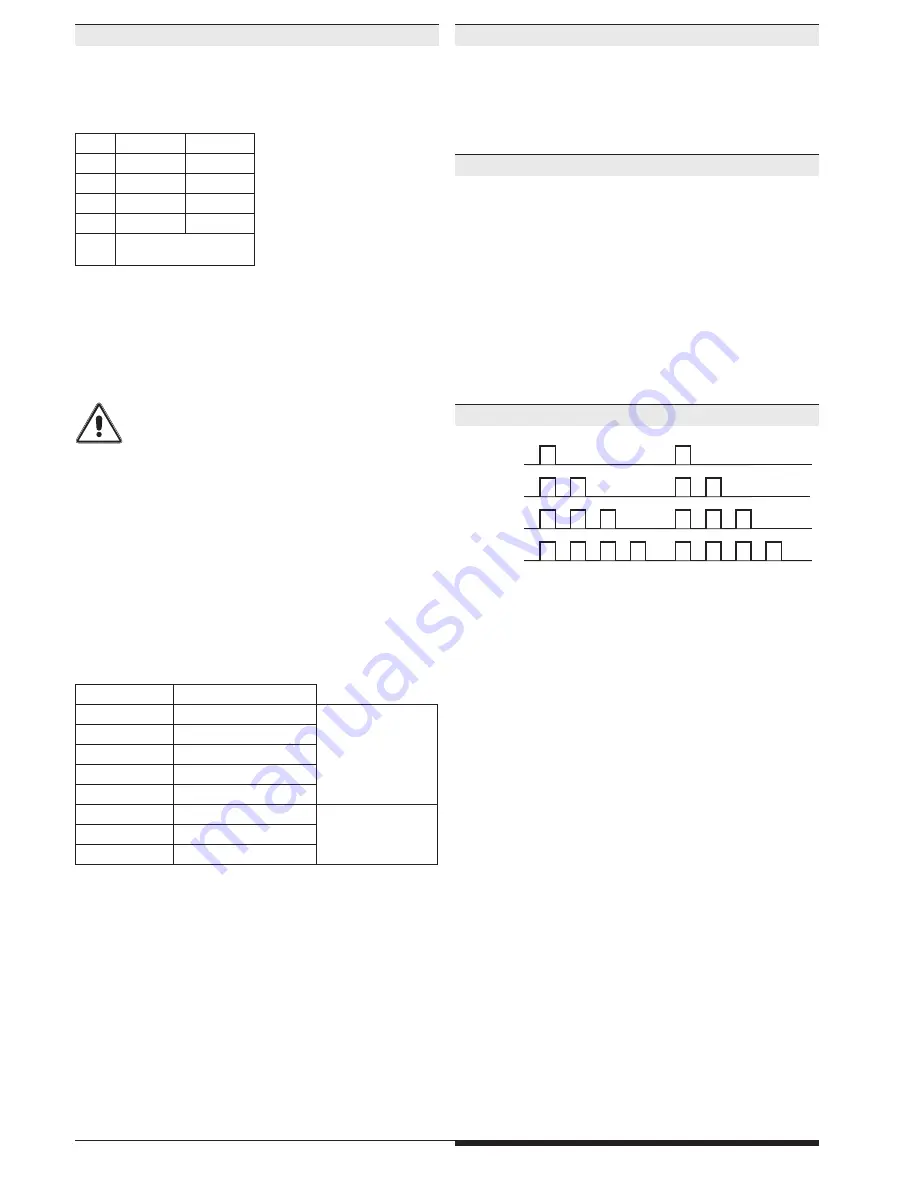

Fault Indication by Flashing Code

simultaneity

error

Potentiometer or

adjustment failure

line fault across

start button

Cross fault or

wiring fault

M10697_a