5.

INSTALLATION

Tapflo LPX series

17

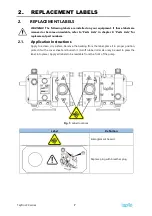

Fig. 11:

Correct Piping to Prevent Inlet Air Pockets

If the pump is installed above the supply liquid level, the piping on inlet side must slope up

toward the pump, preventing air pockets in the pipes (Figure 11).

5.3.

Install check valves

5.3.1.

Inlet side on lift applications

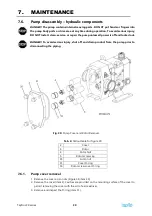

Fig. 12:

Inlet Check Valve

Use check valves to keep the inlet line full, particularly with low-viscosity fluids (Figure 12).

A. Inlet Check Valve

B. Foot Check Valve

5.3.2.

Discharge side

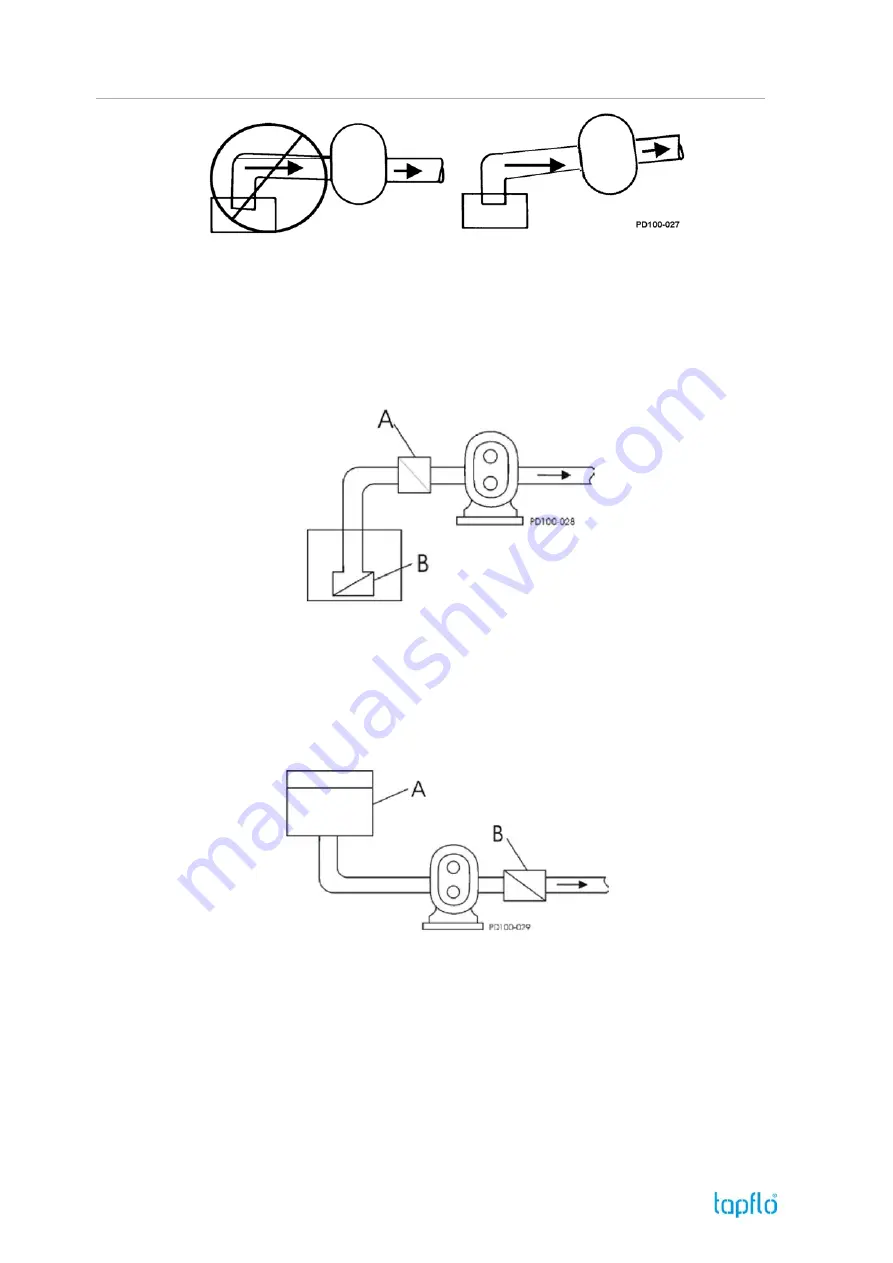

Fig. 13:

Discharge Check Valve

For systems with liquid under a vacuum, we recommend installing a check valve on the

discharge side of the pump. The check valve prevents backflow (air or fluid) to aid in the initial

start-up by minimizing the required differential pressure supplied by the pump to start the

flow (Figure 13).

A. Closed Tank - produces a vacuum on liquid (Low Absolute Pressure)

B. Check Valve (outlet)

Summary of Contents for LPX Series

Page 59: ...9 PARTS LISTS Tapflo LPX series 59 9 3 Model 25 1 to 50 1 Pump Parts B exploded view ...

Page 61: ...9 PARTS LISTS Tapflo LPX series 61 9 5 Model 50 2 to 100 1 Pump Parts A exploded view ...

Page 63: ...9 PARTS LISTS Tapflo LPX series 63 9 7 Model 50 2 to 100 1 Pump Parts B exploded view ...

Page 69: ...Tapflo LPX series 69 ...