7.

MAINTENANCE

Tapflo LPX series

28

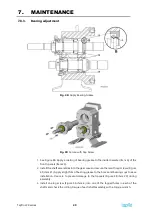

Fig. 29:

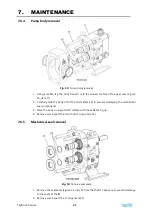

Bearing deflection check

Check bearing condition

With the fluid head and seals removed, check the bearing condition by applying (by hand) an

up or down force of approximately 30 lbs. (14 kg). If movement is detected, the bearing may

be failing.

Check the shaft movement forward or backward. When the bearing is determined to be failing,

replace the bearing and review the lubrication schedule.

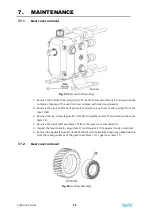

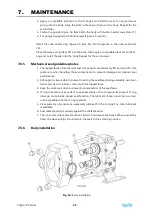

7.3.5.

Recommended maintenance schedule

Item

Grease Quantity per Bearing

Replace Gear Oil

Every 1000 hours.

See chapter. 8.2.2.:

“Gear Oil”.

Grease Bearings

Every 250 hours.

See chapter 7.2.3.:

“Bearing Lubrication”.

Replace O-Rings

Every time O-rings are removed.

NOTE!

For seals and rotors, component life varies widely between different applications.

Inspect for wear and replace as needed. See chapter 7.4:

“Maintenance Inspection

Chart”.

Summary of Contents for LPX Series

Page 59: ...9 PARTS LISTS Tapflo LPX series 59 9 3 Model 25 1 to 50 1 Pump Parts B exploded view ...

Page 61: ...9 PARTS LISTS Tapflo LPX series 61 9 5 Model 50 2 to 100 1 Pump Parts A exploded view ...

Page 63: ...9 PARTS LISTS Tapflo LPX series 63 9 7 Model 50 2 to 100 1 Pump Parts B exploded view ...

Page 69: ...Tapflo LPX series 69 ...