7.

MAINTENANCE

Tapflo LPX series

40

7.8.3.

Bearing adjustment

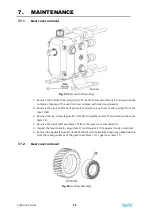

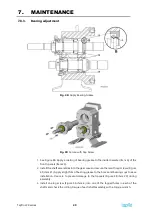

Fig. 48:

Apply Bearing Grease

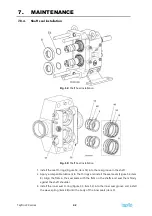

Fig. 49:

Secure with Cap Screw

1.

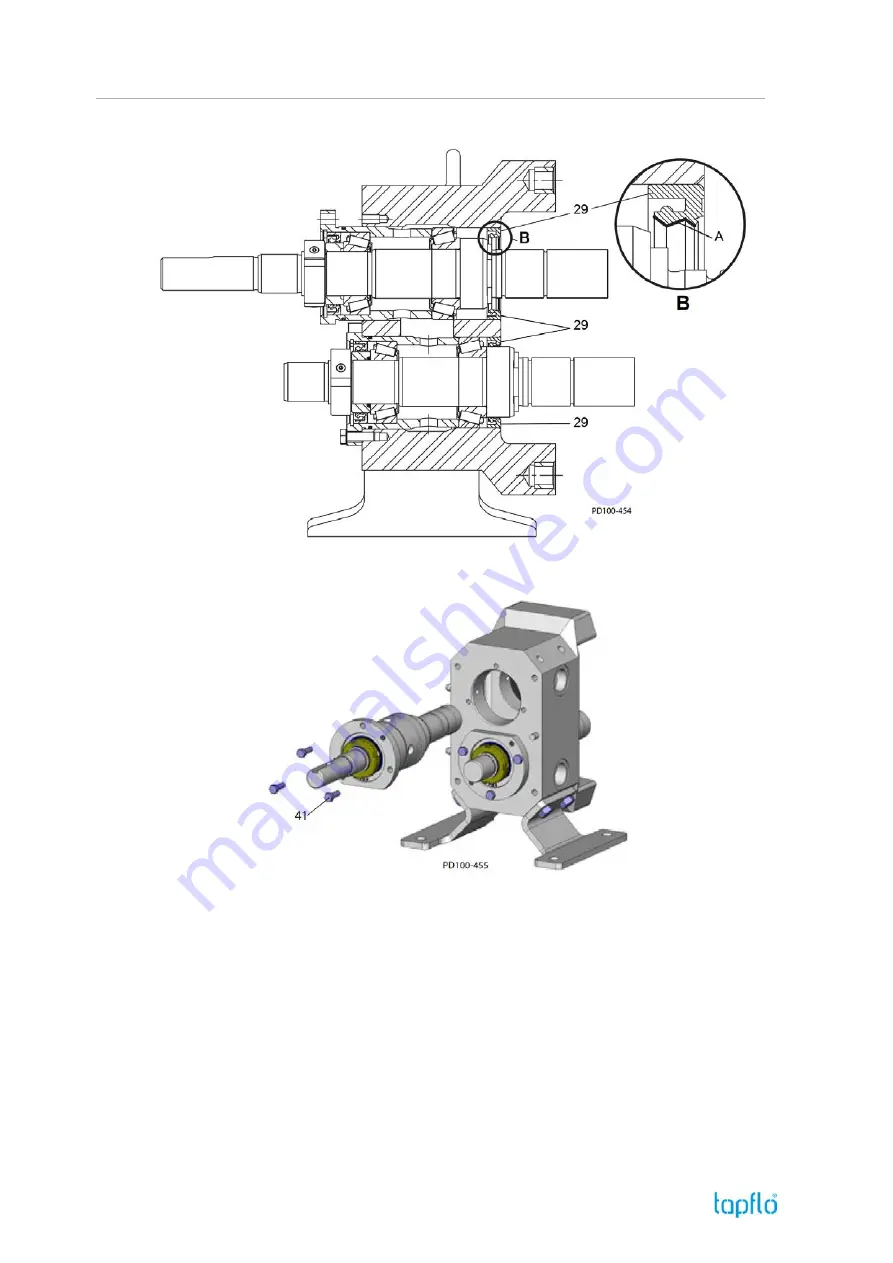

See Figure 48. Apply a coating of bearing grease to the inside diameter (item A) of the

front lip seals (item 29).

2.

Install the shaft assemblies into the gear case and secure them with cap screws (Figure

49, item 41). Apply a light film of bearing grease to the bores and bearing cups to ease

installation. Use care to prevent damage to the lip seals (Figure 48, item 29) during

assembly.

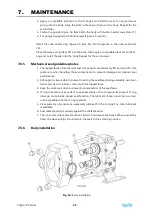

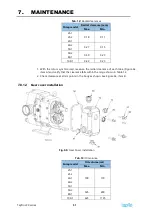

3.

Install one lug screw (Figure 50, item 4) into one of the tapped holes in each of the

shafts and check the rolling torque of each shaft assembly with a torque wrench.

Summary of Contents for LPX Series

Page 59: ...9 PARTS LISTS Tapflo LPX series 59 9 3 Model 25 1 to 50 1 Pump Parts B exploded view ...

Page 61: ...9 PARTS LISTS Tapflo LPX series 61 9 5 Model 50 2 to 100 1 Pump Parts A exploded view ...

Page 63: ...9 PARTS LISTS Tapflo LPX series 63 9 7 Model 50 2 to 100 1 Pump Parts B exploded view ...

Page 69: ...Tapflo LPX series 69 ...