7.

MAINTENANCE

Tapflo LPX series

48

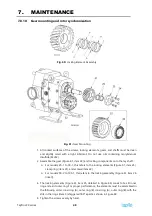

7.8.10.

Gear mounting and rotor synchronization

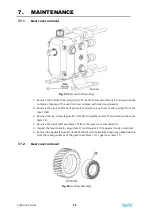

Fig. 60:

Locking Element Assembly

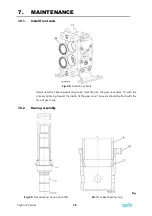

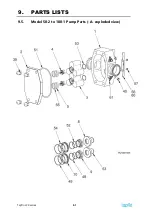

Fig. 61:

Gear Mounting

1.

All contact surfaces of the screws, locking elements, gears, and shafts must be clean

and slightly oiled with a light lubricant. Do not use oils containing molybdenum

disulfide (MoS2).

2.

Assemble the gear (Figure 61, item 22) and locking components onto the lay shaft.

For models 25-1 to 50-1, this refers to the locking elements (Figure 61, item 25),

clamp ring (item 23), and screws (item 24).

For models 50-2 to 100-1, this refers to the locking assembly (Figure 61, item 26

(inset)).

3.

The locking elements (Figure 61, item 25, detailed in Figure 60) consist of a slit inner

ring and a slit outer ring. For proper performance, the elements must be assembled in

the following order: inner ring (A), outer ring (B), inner ring (A), outer ring (B); with the

slits in the rings (item C) staggered 180° apart as shown in Figure 60.

4.

Tighten the screws evenly by hand.

Summary of Contents for LPX Series

Page 59: ...9 PARTS LISTS Tapflo LPX series 59 9 3 Model 25 1 to 50 1 Pump Parts B exploded view ...

Page 61: ...9 PARTS LISTS Tapflo LPX series 61 9 5 Model 50 2 to 100 1 Pump Parts A exploded view ...

Page 63: ...9 PARTS LISTS Tapflo LPX series 63 9 7 Model 50 2 to 100 1 Pump Parts B exploded view ...

Page 69: ...Tapflo LPX series 69 ...