1. INSTALLATION

IOM manual Tapflo PTL Hose pumps

14

1.8.7.

Rotating parts

Do not tamper with the protection of the rotating parts, do not touch or approach rotating

parts in movement.

1.8.8.

Cleaning and disinfection

Cleaning and disinfection of the pump system is of greatest importance when the pump is used

in a food process installation. Use of a pump system that is NOT cleaned or disinfected can

cause contamination of the product

1.9.

Installation recommendations

➢

If liquid contains sold particles bigger than max allowable size for the corresponding pump

size, a strainer on the suction side should be used.

➢

Manometers or pressure sensors must always be installed on the suction and discharge

side of the pump to determine proper operation of the pump.

➢

The suction and dishcarge piping must be fastened properly so that no strain occurs on

the pump manifolds.

➢

It is recommended to install a check-valve on the discharge side in order to protect the

pump from water hammer effect that can be created in the discharge pipeline.

➢

The suction line should be as short and straight as possible.

➢

A gate valve could be installed on the discharge line for easier pump disconnection from

the pipeline (

ATTENTION!

The gate valve should never be closed during pump

operation).

➢

A pressure relief valve must be assembled obligatory on the discharge side by the

customer if overpressure in the system is possible. A device must be incorporated into the

pump, system, or drive, to prevent the pump exceeding the rated pressure.

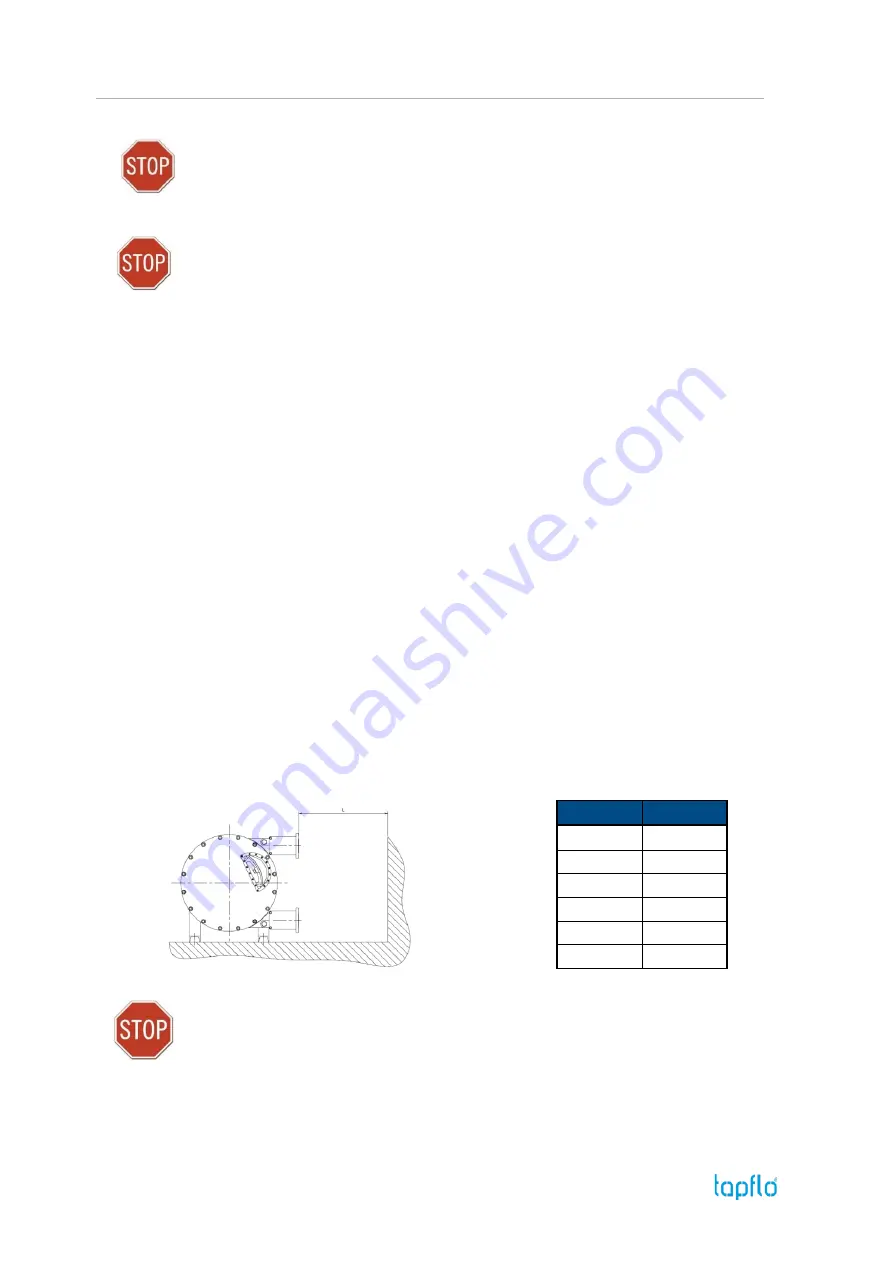

1.9.1.

Minimum required distance for hose removal

During pump installation provide enough space to be able to perform hose replacement

procedure. Follow the guidline below:

PUMP

L [mm]

PTL9

400

PTL13

400

PTL17

600

PTL25

700

PTL30

1200

PTL45

1500

NOTE!

Even if all above safety instructions are met and complied with, there still exists a minor danger

in the event of a leakage or mechanical damage of the pump. In such case the pumped product

can emerge on sealing areas and connections.

Summary of Contents for PTL Series

Page 63: ......