5. Maintenance and inspection

IOM manual

–

SF & SFA series

25

NOTICE:

➢

The drained oil must be disposed according

to national and local regulations.

➢

The gasket and the O-ring for the oil filler

plug must be replaced with a new part at

each oil inspection and change.

Model

Oil volume

SF

165 ml

SFA

165 ml

5.5.

Disassembly and reassembly procedure

DANGER:

Disconnect and lock out electrical power before installing or servicing the unit

WARNING:

Make sure to perform a trial operation when starting the pump after a reassembly

.

If the

pump was assembled improperly, it may leakage abnormal operation or electrical shock

.

CAUTION:

Wear protective gloves. A worn impeller and/or pump housing can have very sharp edges.

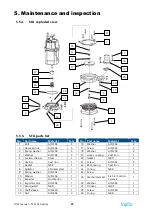

5.5.1.

SF disassembly procedure

NOTICE:

➢

Before disassembling, make sure to drain the oil from the pump.

➢

Mechanical seal should be replaced only when broken or worn (see chapter

5.4.

Oil inspection and change

).

1. Strainer [2] disassembly

Remove the screw [1] to remove the strainer [2].

2. Pump casing [5] disassembly

Remove the screw [3] and spring washer [4] to remove the pump cover [5] and the gasket

[6].

3. Impeller [10] disassembly

Remove agitator [7], spring washer [8], and washer [9]; then remove the impeller [10],

impeller adjusting shim [11], sand guard [12] and shaft sleeve [13].

4. Back casing [21] and mechanical seal [24] disassembly

After removing the screw [20], remove the back casing [21] (when doing this, be careful

not to damage sealing face of the mechanical seal [24]) and casing O-ring [22]. Remove

the mechanical seal from the main shaft.

NOTICE:

Mechanical seal replacement must be handled by the qualified staff, contact Tapflo

for more information.