SF-2200H Flame / Plasma CNC Cutting System Operating Manual

16

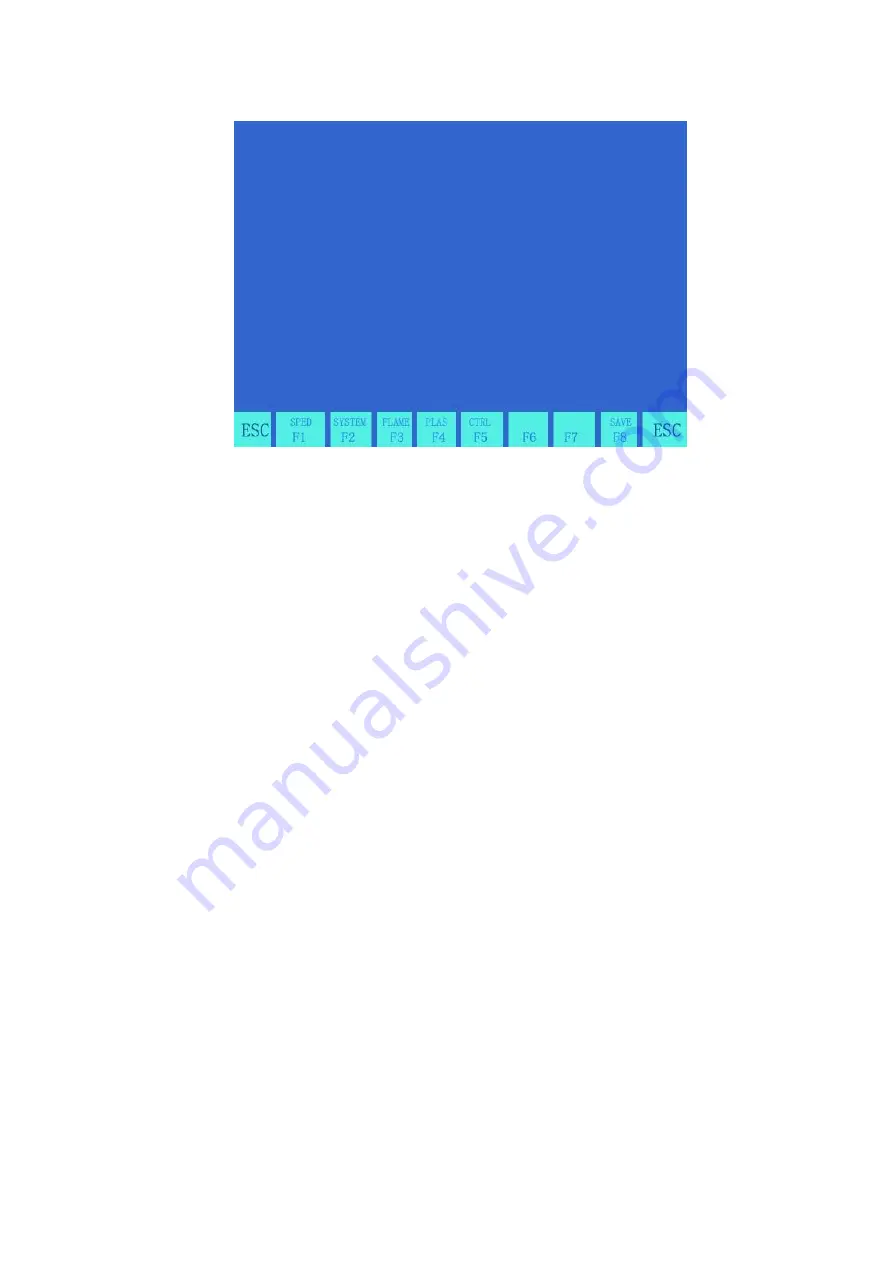

Section 6 Parameter Setting

Under system main menu, press

【

F3

】

to enter display interface as below:

:

6.1、Parameter Setup

Including:

SPED

---- Speed parameters, including

STARTUP

(start speed),

TIMING

( Adjust time) and

HIGH SPD

(Max

limit speed);

SYST

----System parameters, including NUMERATOR, DENOMINA-(electronic gear

numerator/denominator), MA-ORIGIN(machine tool origin), REFERENCE(reference point),

CLEARANCE, OFFSET, S, SOFTLIMI-;

FLAME

--- Flame parameters, including IGNITION(ignition time), HOTUP TIME(preheat time), TORCHUP

TIME(torch up time),TORCHDN TIME( torch down time), PIERCEUP(pierce torch up time),

PIERCEDN TIME(pierce torch down time);

PLAS

--- Plasma parameters, including torch locate time, Arc on M order, Arc off M order, Arc-feedback,

Locate check, Locate Logic, Pierce time;

CTRL

----Control parameters, including flame/plasma mode select, cutting limit speed, Extend pierce, Shape

Max point etc.

SAVE

----Save function, save the amended parameters.

Attention: Want to make the amended parameters enable, press

【

F6

】

to save.

Under PARA menu,

input

“1928” command, system will hint:

NOTIC: SETUP FACTORY PARAMS

This moment, The amended parameters will be saved to

“Factory parameters”, that is When you press

“GG3” and

1) select

“PARAMETER”, it will initialize parameters by amended value.

6.2

、

Figure Setting

图 6.1Parameter setting main menu