20

protection will not protect the operator from an

electrical shock due to improper grounding

practice, frayed or cracked extension cords, or

other defective electrical components. This

exposure to electrical shock increases greatly

whenever the equipment is used around water or

other conductive fluids. The operator will be

provided with electrical shock protection whenever

the machine is connected to a circuit that has a

Ground Fault Circuit Breaker. The Ground Fault

Circuit Breaker will open the circuit whenever it

senses a fault current, greater than a few

milliamps, in the ground path. If a receptacle with a

Ground Fault Circuit Breaker is not available, a

Portable Ground Fault Circuit Interrupter [MM] [See

FIG. 7] can be used at the branch receptacle to

provide the same level of protection.

Gasoline Model:

Engine Fuel: Check the engine operation manual.

Unleaded gasoline is recommended.

Engine Oil: Put the AXLE in the OPERATION

POSITION [F] [See FIG. 11] so that the engine is in

a horizontal position, then, check that the engine oil

level is correct. Check the oil level frequently to

ensure that the level never falls below that

specified in the engine operation manual. If the oil

level is low, add SAE 10W30, service classification

SF or SG oil (for normal conditions) as

recommended in the engine operation manual. DO

NOT overfill engine with oil!

Before starting the engine verify that the Throttle

Lever [L] is between the START [N] and STOP [M]

position. This will allow the engine to be started

while the clutch is disengaged. NOTE: The engine

clutch will engage at 1800 RPM, and the Accessory

Disks [P] will begin to rotate.

Before starting the engine, verify that the engine

does NOT exceed 20 degrees angle of inclination

when the unit is in operation.

WARNING:

Run the machine only if the

grinding heads are on the ground. Raising the

front of the machine with the engine or motor

running could cause injury or death to by-

standers or the operator. Also, engine

inclination angles greater than 20 degrees

could cause severe engine damage and void

your engine warranty!

4. Tool Installation

TOOL INSTALLATION:

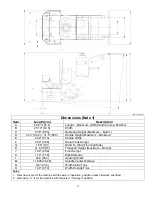

1) Rear Axle Position (See FIG. 11): Make sure the

Axle is in the Transport Position [E]. Using TABLE

3 (below) install the Axle Stop Bolts [G] in the

proper position for the tool being mounted. The

Axle Stop Bolts [G] are factory installed in the F2

position.

Table 3 shows the tools specified by our

company. Tools from other manufactures

may fit onto this machine. Measure “Tool

Height” to determine the proper axle position

(See TABLE 4) for these tools.

TABLE 3

Rear Axle Positions (See FIG. 11)

Tool

Tool Height

Axle Position

Grinding Stones

2.0” (51 mm)

F2

Tungsten Carbide

Block

2.1” (53 mm)

F2

Diamond Segment

Block

2.1” (53 mm)

F2

Star wheels

2.25” (57 mm)

F2

Beam Cutter Wheels

2.25” (57 mm)

F2

TC Wheels

2.15” (54 mm)

F2

Diamond Disks

2” (51 mm)

F2 or E2

Scrubbing Pad

(with Adapter)

1.7”

(43.2mm)

F3

If the tool to be installed is not listed in TABLE 3:

a) Measure the “Tool Height”.

TABLE 4

Tool Height for Axle Positions (See FIG. 1)

Axle Position

Minimum Tool Height

F1

2.44” (62 mm)

F2

2.00” (50.8 mm)

F3

1.69” (42.9 mm)

F4

1.00” (25.4 mm)

b) Using TABLE 4, find a “Minimum Tool Height”

equal to, or greater than, the measured tool height.

c) Referencing FIG. 11, install and tighten the Axle

Stop Bolts [G] in the Axle Position (F1, F2, etc)

determined from step b) above.

2) Raise Front Shield (A): Loosen the three (3)

Capscrews [B] that hold the Front Shield [A] in

position. Raise the Front Shield to its upper

position, then tighten the Capscrews [B] to hold it in

place.

3) Tilt Machine Backwards: When on a flat surface,

tilt the machine backward until the Handles [FF]

rest on the ground. If you are not sure the machine

will stay in this position, add a weight or other

device to the handle to secure them to the ground.

WARNING: Make sure the machine is stable

when the front end is raised into the air!

Secure the machine in this position if you are

not sure about its stability. Secure machine

BEFORE starting attachment of the tools to

the accessory disks!

4) Tool Installation on Accessory Disk [P]:

See FIG. 14, FIG. 15, FIG. 16, FIG. 26, FIG. 27

a) Place

the

Tool [GG 1] so that it rests against the

back and outside of the tool holding area of the

Summary of Contents for DT11H

Page 7: ...7...

Page 8: ...8...

Page 9: ...9...

Page 10: ...10...

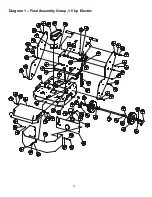

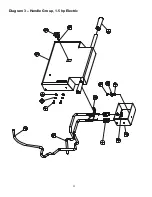

Page 28: ...28 Diagram 1 Final Assembly Group 1 5 hp Electric...

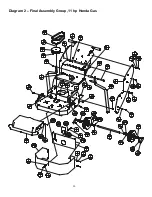

Page 30: ...30 Diagram 2 Final Assembly Group 11 hp Honda Gas...

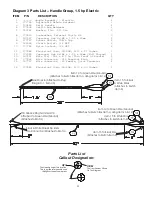

Page 32: ...32 Diagram 3 Handle Group 1 5 hp Electric...

Page 36: ...36 Diagram 5 Motor Group 1 5 hp Electric...

Page 38: ...38 Diagram 6 Engine Group 11 hp Honda...

Page 40: ...40 Diagram 7 Gearbox Assembly All Models...

Page 42: ...42 Diagram 8 Water Tank Kit Optional P N 177855 Complete Kit...

Page 50: ...50 Diagram 15 Wiring Diagram 1 5hp Electric Model...