EN BACKPACK SPRAYER

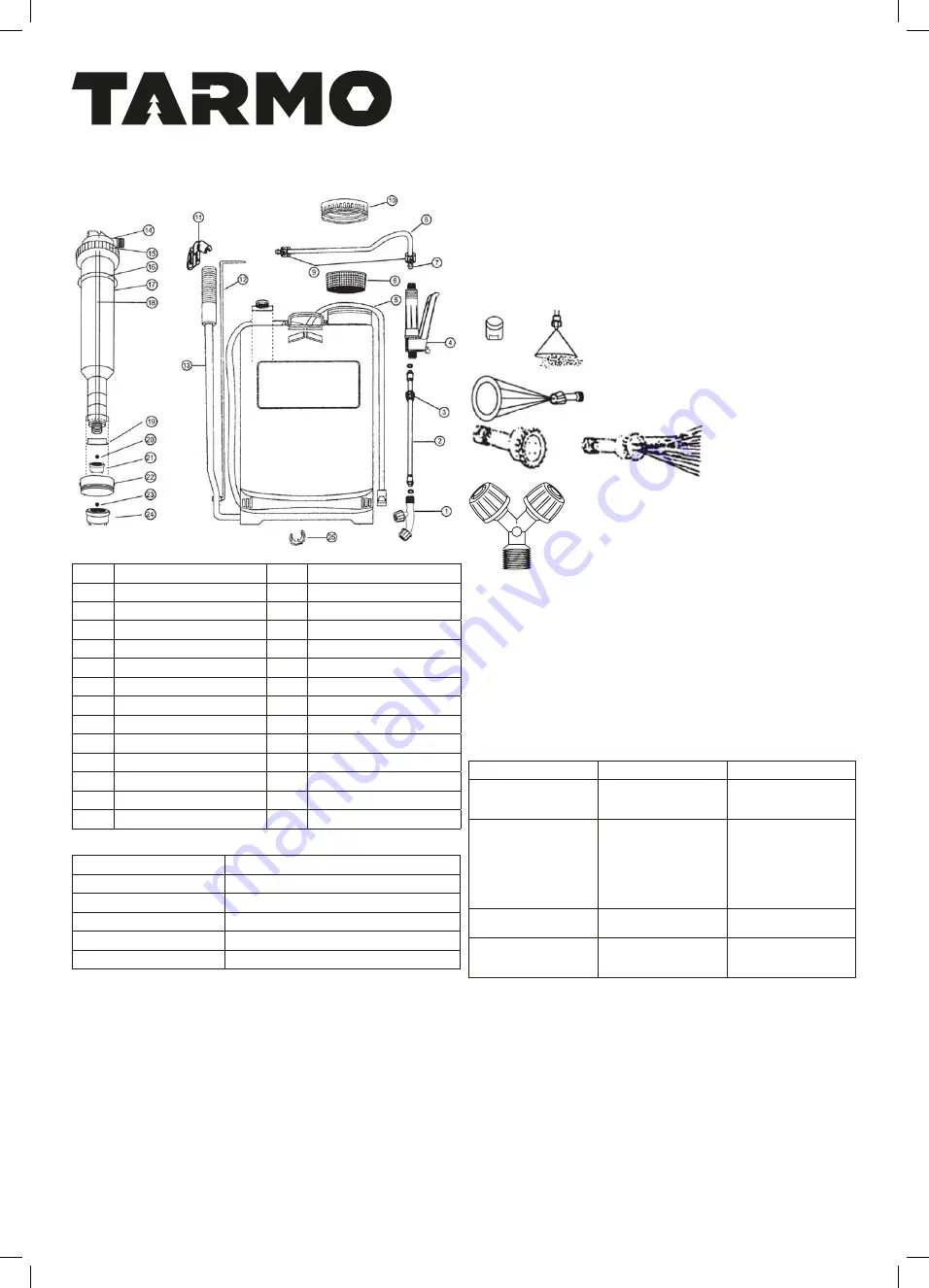

No.

Name

No.

Name

1

spray head

14

air chamber cap

2

spray rod

15

adjustment ring

3

spray rod nut

16

seal ring

4

operation handle

17

air chamber

5

strap

18

water outlet tube

6

filter

19

piston seal

7

hose valve

20

sealing ball

8

hose

21

water outlet valve

9

hose nut

22

pump

10

container cap

23

sealing ball

11

operation arm clamp

24

water inlet valve

12

connecting rod

25

fixing buckle

13

operation arm

SPRAYER SPECIFICATIONS

Operating pressure

29–58 PSI

Max. air chamber pressure

145 PSI

Flow rate

0.5–1.6 l/min

Pump type

Manual hand pump

Air chamber capacity

0.8 l

Container capacity

16 l

BEFORE USE

Do not spray inflammable liquids with this sprayer.

Do not try to pump excess pressure into the sprayer. Only use moderate force and pump

6–10 times to reach the appropriate operating pressure. Failure to comply with this

instruction could damage the sprayer.

Wear appropriate personal protective equipment depending on the liquid being sprayed.

Do not use hot liquids with this sprayer.

Clean the sprayer with water after operation to prevent the used liquid from corroding the

sprayer or blocking the sprayer head.

Store the sprayer in a dry and cool place. Do not leave it in direct sunlight after use.

Do not spray caustic or corrosive solutions with this sprayer.

INSTRUCTIONS

The basic operation of the backpack sprayer is simple. Add liquid (water, pesticide,

detergent etc.) to the container, swing the arm to pump pressure into the air chamber and

press the operation handle to release the liquid from the nozzle as a spray.

Assemble the sprayer so that it corresponds to the drawing.

After assembling the sprayer, remove the cap and pour the liquid through the filter part

into the container. After filling the container, close the cap tightly.

Put the backpack sprayer on your back and adjust the carrying strap if needed.

Use the operation arm to increase pressure in the air chamber. Usually 6–10 times press-

ing the arm is sufficient for good operating pressure. Do not try to apply excess pressure

to the sprayer.

Use the operation handle to release the pressure and start spraying.

USING THE SPRAYER NOZZLES

The sprayer comes with 4 nozzles: the fan-style nozzle, conical spray head, adjustable

4-hole spray head and double nozzle.

Fan-style spray head

Conical spray head

Adjustable spray head

Double nozzle

With the fan-style nozzle, you can spray the liquid evenly: it is suitable for spraying on low

and short-stalked crops and for spraying weed killer. It is also a good universal nozzle for

most purposes.

The conical nozzle is specially designed for spraying pesticides and insecticides.

The adjustable 4-hole nozzle is meant for spraying high-stalked crops, trees and other

high objects.

MAINTENANCE AND TROUBLESHOOTING

Remember to always rinse the sprayer with clean water after use.

Apply lubricant to the sealing washer of the air chamber regularly and before storing the

sprayer for a long time.

When storing the product, protect it from direct sunlight and freezing conditions.

PROBLEM

CAUSE

SOLUTION

Leakage.

Seal ring is damaged or not

installed properly.

Check the seal ring’s condition

and install it properly or

replace it if necessary.

Pressure cannot be increased

to sufficient operating

pressure.

Either the piston seal (part

19) or the sealing ball (part

20) is worn. There is a major

blockage in some part of the

pump system.

Disassemble the air chamber

construction (parts 14–24),

rinse the parts thoroughly to

get rid of any blockage and

assemble them again carefully

according to the instructions.

If part 19 or 20 appears to be

worn, replace it.

When operating the arm, no

pressure is felt.

The sealing ball (part 20) is

missing or broken.

Check and replace the sealing

ball.

Part deformation.

Sprayer is being operated

under excessive pressure.

Replace parts if necessary and

pay attention to the appropri-

ate pressure.

327518

ko1219

Info/ Tootja/ Ražotājs/ Gamintojas/ Изготовитель:

Tarmo Finland, PO Box 499,FI-33101

Tampere, Finland/ Тампере, Финляндия

327518_painesumutinreppu_ko.indd 3

327518_painesumutinreppu_ko.indd 3

3.1.2020 7.32.54

3.1.2020 7.32.54