Reviews:

No comments

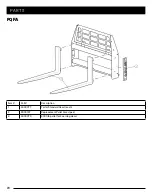

Related manuals for PFQA

150H

Brand: Cascade Pages: 11

100G

Brand: Cascade Pages: 16

XRM945

Brand: Xtreme Manufacturing Pages: 76

A029087

Brand: Bishamon Pages: 10

13174850

Brand: Bishamon Pages: 11

UT13PTE

Brand: UTILEV Pages: 29

EA15 Series

Brand: EKKO Pages: 9

Walkie EB16EA

Brand: EKKO Pages: 28

EP30A

Brand: EKKO Pages: 32

EK13A

Brand: EKKO Pages: 28

EOP68

Brand: EKKO Pages: 33

EK18RR

Brand: EKKO Pages: 34

EK07S Series

Brand: EKKO Pages: 38

EK20R

Brand: EKKO Pages: 42

EK18A

Brand: EKKO Pages: 41