12

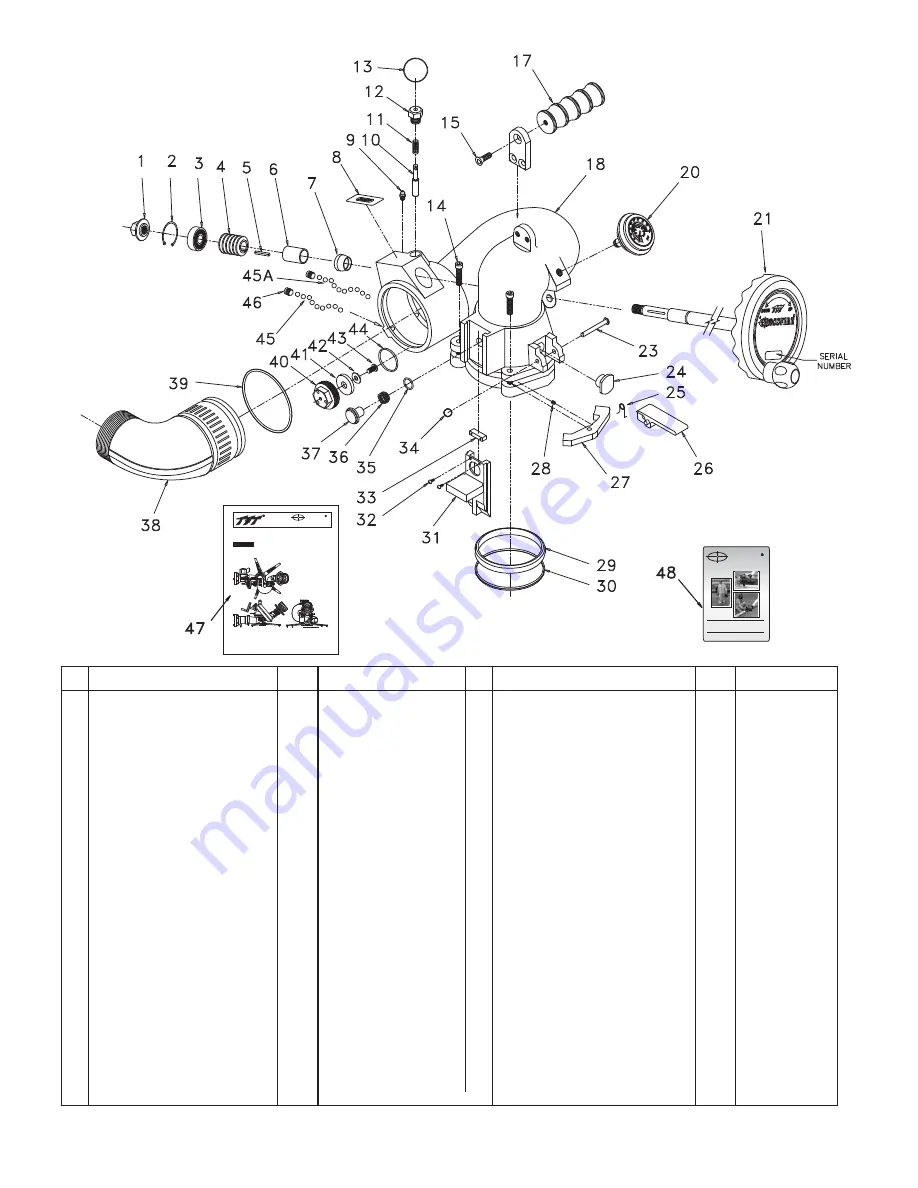

#

DESCRIPTION

QTY

PART #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

17

18

20

21

23

24

SHAFT NUT

1

X210

SNAP RING

1

VR4220

BEARING

1

VM4250

WORM WITH KEYWAY

1

X220

KEY 1/8 X 1.00

1

X225

BUSHING

1

X230

BOOT

1

X240

DANGER LABEL

1

XL090

11/4-28 GREASE FITTING

1

VT25-28ZERK

PULL PIN

1

X340

PULL PIN SPRING

1

X345

PULL PIN HOUSING

1

X350

KEY RING

1

VR4300

5/16-18 X 1-1/4 SHCS

2

VT31-18SH1.2

3/8-16X7/8SHCS

1

VT37-16SH875

PEG - CARRYING HANDLE

1

X362

BIG BEND/BELL ASSEMBLY

1

X800**

200 PSI/BAR GAGE/BUMPER

1

X823

HANDWHEEL ASSEMBLY

1

X810

ROTATION LOCK PIVOT

1

X180

ROTATION LOCK INSERT

1

X170

25

ROTATION LOCK SPRING

1

X152

26

ROTATION LOCK LEVER

1

X821

#

DESCRIPTION

QTY

PART #

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

45A

46

47

48

PAWL

2

X135

DETENT SPRING

2

H770

WEAR STRIP

1

X120

CUP SEAL .366 NITRILE 70A

1

X125

SLIDE BAR

1

X140

#6-32 X 1/4 BUTTON HEAD

2

VT06E32BH250

COVER

1

X142

CLEVIS PIN RETAINER

1

X137

O-RING-018

1

VO-018

PLUNGER WAVE SPRING

1

X165

SAFETY PLUNGER

1

X150

2.5 NH ELBOW/VANE ASSEMBLY

1

X339NJ**

O-RING-241

1

VO-241

DRAIN HOUSING

1

X375

DRAIN PLUG

1

X382

FLAT WASHER

1

VW687X281-50

1/4-28 X 1/2 BHCS

1

VT25-28BH500

O-RING 130

1

VO-130

5/16 SS BALLS

38

VB.312

5/16 TORLON BALLS

38

VB.312TO

3/8-24 x 3/8 SOCKET SET

2

VT37F24SS312

MANUAL - CROSSFIRE WITH

1

LIX-040

STOW-A-WAY BASE

DVD - CROSSFIRE

1

LIX-200

8.0 DRAWINGS & PARTS LIST

** NOTE: Specify desired color and hose thread at time of order.

CROSSFIRE

Model No. XFT-NJ

®

INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

INSTRUCTIONS FOR SAFE OPERATION AND MAINTENANCE

Read instruction manual before use. Operation of this device

without understanding the manual and receiving proper training is a

misuse of this equipment. A person who has not read and

understood all operating and safety instructions, is not qualified to

operate the CROSSFIRE portable/deck gun.

Read instruction manual before use. Operation of this device

without understanding the manual and receiving proper training is a

misuse of this equipment. A person who has not read and

understood all operating and safety instructions, is not qualified to

operate the CROSSFIRE portable/deck gun.

This instruction manual is intended to familiarize firefighters and maintenance

personnel with the operation, servicing, and safety procedures associated with the

C R O S S F I R E

p o r t a b l e / d e c k

g u n .

This manual should be kept available to all operating and maintenance personnel.

This instruction manual is intended to familiarize firefighters and maintenance

personnel with the operation, servicing, and safety procedures associated with the

C R O S S F I R E

p o r t a b l e / d e c k

g u n .

This manual should be kept available to all operating and maintenance personnel.

Maximum recommended

flow is 1250 GPM on

truck mount adaptor, 800

GPM on portable base.

Maximum recommended

inlet pressure is 175 psi.

Maximum recommended

flow is 1250 GPM on

truck mount adaptor, 800

GPM on portable base.

Maximum recommended

inlet pressure is 175 psi.

CROSSFIRE

DANGER

MANUAL:

WITH STOW-A-WAY 800 BASE

MANUAL:

WITH STOW-A-WAY 800 BASE

OPERATIONS MANUAL:

DVD SUPPLEMENT

CROSSFIRE

This DVD is not intended to replace the reading and

understanding of the CROSSFIRE operations manual.

The safest, most versatile

master stream device...Ever!