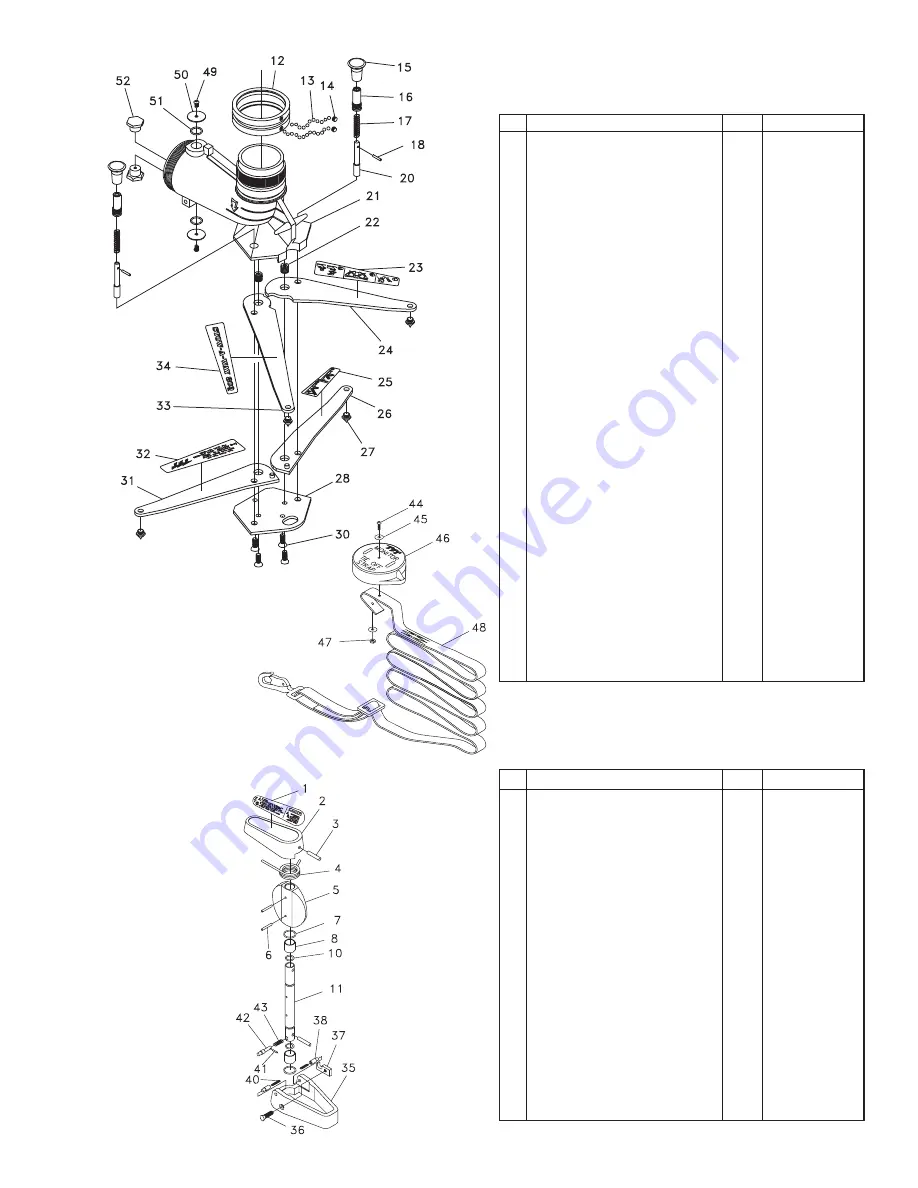

13

#

DESCRIPTION

QTY

PART #

1

2

3

4

5

6

7

8

10

11

35

36

37

38

40

41

42

43

SAFETY VALVE HANDLE LABEL

1

XL070

VALVE HANDLE

1

X540

1/4 x 1 3/8 SPIROL PIN

1

VP250X1.375H

TORSION SPRING

1

X560

BUTTERFLY

1

X550

5/32 x 1 1/8 SPIROL PIN

3

V1920

O-RING-118

2

VO-118

BUSHING

2

X565

O-RING-113

2

VO-113

VALVE SHAFT

1

X570

PADDLE

1

X530

1/4-20 x 7/8 FLAT HEAD

1

VT25E20FH875

WEAR PLATE

1

X585

PADDLE PIVOT

2

X590

PADDLE PIVOT SPRING

2

X575

3/32 x 1/2 SPIROL PIN

1

VP094X500H

TRIP PIN

1

X580

TRIP PIN SPRING

1

X582

STOW-A-WAY 800

®

without Safety Valve

#

DESCRIPTION

QTY

PART #

12

13

14

15

16

17

18

20

21

22

23

24

25

26

27

28

30

31

32

33

34

44

45

46

47

48

49

50

51

52

SWIVEL RING

1

X425

5/16 SS BALLS

76

VB.312

SWIVEL SCREW

2

X405

SHOT PIN KNOB

2

X430

KNOB BARREL

2

X440

SHOT PIN SPRING

2

X445

5/32 x 7/8 SPIROL PIN

2

V1900

SHOT PIN

2

X435

BASE

1

X420

BELLEVILLE WASHER

12

D07590

INSTRUCTION LEG LABEL 1-3

1

XL010

FRONT LEG - LEFT

1

X470L

INSTRUCTION LEG LABEL 4-5

1

XL020

REAR LEG - LEFT

1

X460L

SPIKE

4

X480

BOTTOM PLATE

1

X450

3/8-16 X 3/4 FLAT HEAD SHCS

4

VT37-16FH750

REAR LEG - RIGHT

1

X460R

TFT LEG LABEL

1

XL050

FRONT LEG - RIGHT

1

X470R

SAFE-TAK LEG LABEL

1

XL040

#10-32 x 3/4 BUTTON HEAD

1

VT10E32BH750

STAINLESS STEEL WASHER 18-8

2

V2038

STRAP CAP

1

X457

#10-32 HEX NUT

1

VT10-32NT

STRAP ASSEMBLY

1

RX455

1/4-28 X ½ BUTTONHEAD

2

VT25-28BH500

2.5" CLAPPER WASHER

2

X752

O-RING-118

2

VO-118

PLUG

2

X510

XF500-KIT

VALVE UPGRADE KIT

See

Section

5.6