©Copyright Task Force Tips LLC 2002-2020

6

LIX-030 September 4, 2020 Rev26

3.2 SPECIFICATIONS

Table 3.2

3.3 USE WITH SALT WATER

Use with salt water is permissible provided the equipment is thoroughly cleaned with fresh water after each use. The service life of the

equipment may be shortened due to the effects of corrosion, and is not covered under warranty.

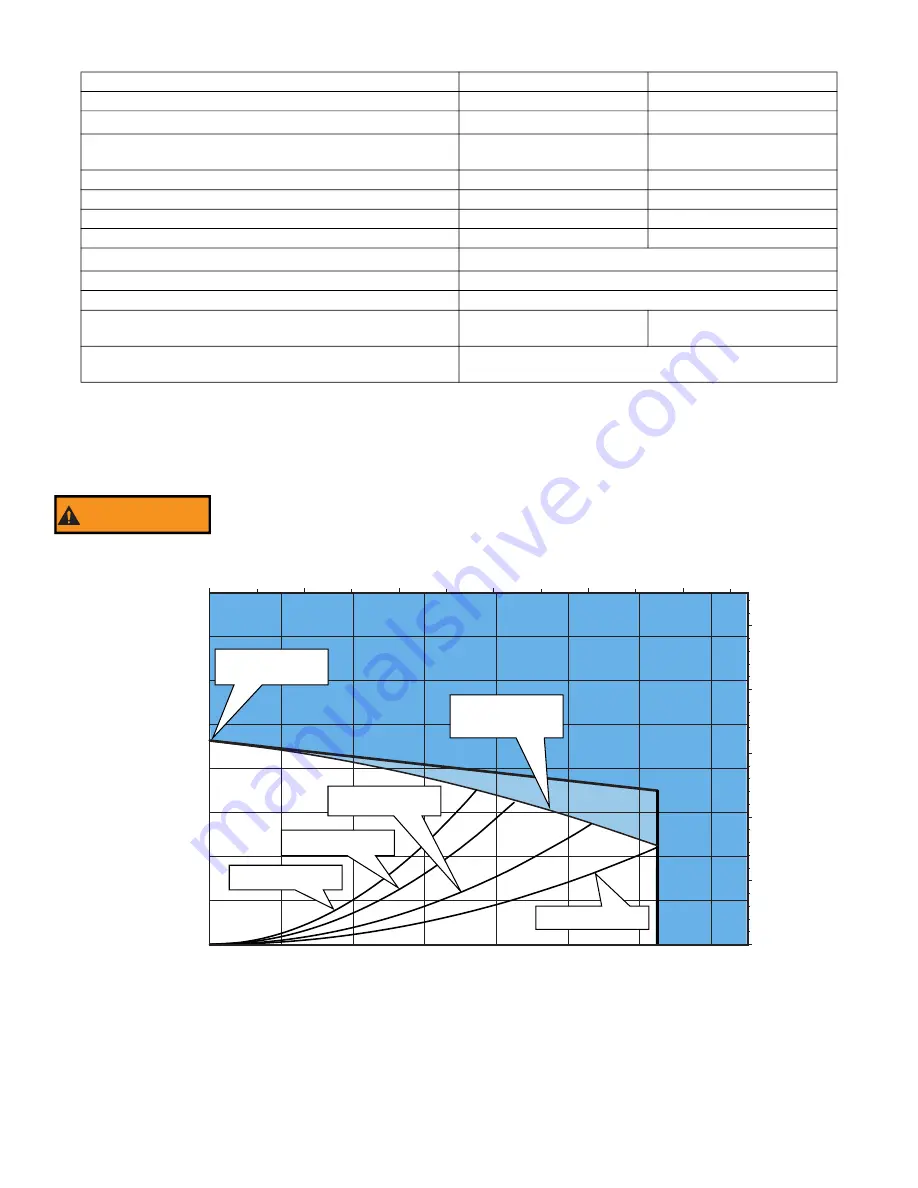

3.4 OPERATING ENVELOPE

Figure 3.4

CROSSFIRE Monitor

SAFE-TAK 1250 Base

Weight

17 lbs (6.7 kg)

24 lbs (10.9 kg)

Storage Volume

4060 in

3

(.066m

3

)

1620 in

3

(.027m

3

)

Dimensions

20 x 14-1/2 x 14 in

(508 x 368 x 355mm)

20 x 9 x 9 in

(508 x 228 x 228mm)

Height Above Truck Flange

12-1/2 in (320mm)

N/A

Height Above Truck Deck (min)

14 in (360mm)

N/A

Height Above Ground on Base

16-1/2 in (420mm)

N/A

Line of Reaction Force Above Ground

4 in (100mm)

N/A

Flow Area (min)

8.3 in

2

(5360mm

2

)

Operating Temperature of Fluid

33 to 120°F (1 to 50°C)

Storage Temperature Range

-40 to 150°F (-40 to 65°C)

Available Inlets

Single

Single and Double

2-1/2 in to 6 in

Materials Used

Aluminum 6000 series hard anodized MIL8625 class 3

type 2, stainless steel 300 series

WARNING

Damage or injury could result from operating the monitor beyond the safe operating envelope. Do

not operate the monitor outside the envelope in the following graph(s).

0

1000

2000

3000

4000

5000

0

5

10

15

20

25

0

50

100

150

200

250

300

350

400

0

200

400

600

800

1000

1200

1400

Flow (l/min)

Pressure (BAR)

Pressure (PSI)

Flow (GPM)

1 3/8" (35mm) Tip

2.0" (50mm) Tip

1 1/2" (38mm) Tip

1 3/4" (44mm) Tip

Maximum Monitor

Inlet Pressure

Maximum Nozzle

Inlet Pressure