©Copyright Task Force Tips LLC 2002-2020

12

LIX-030 September 4, 2020 Rev26

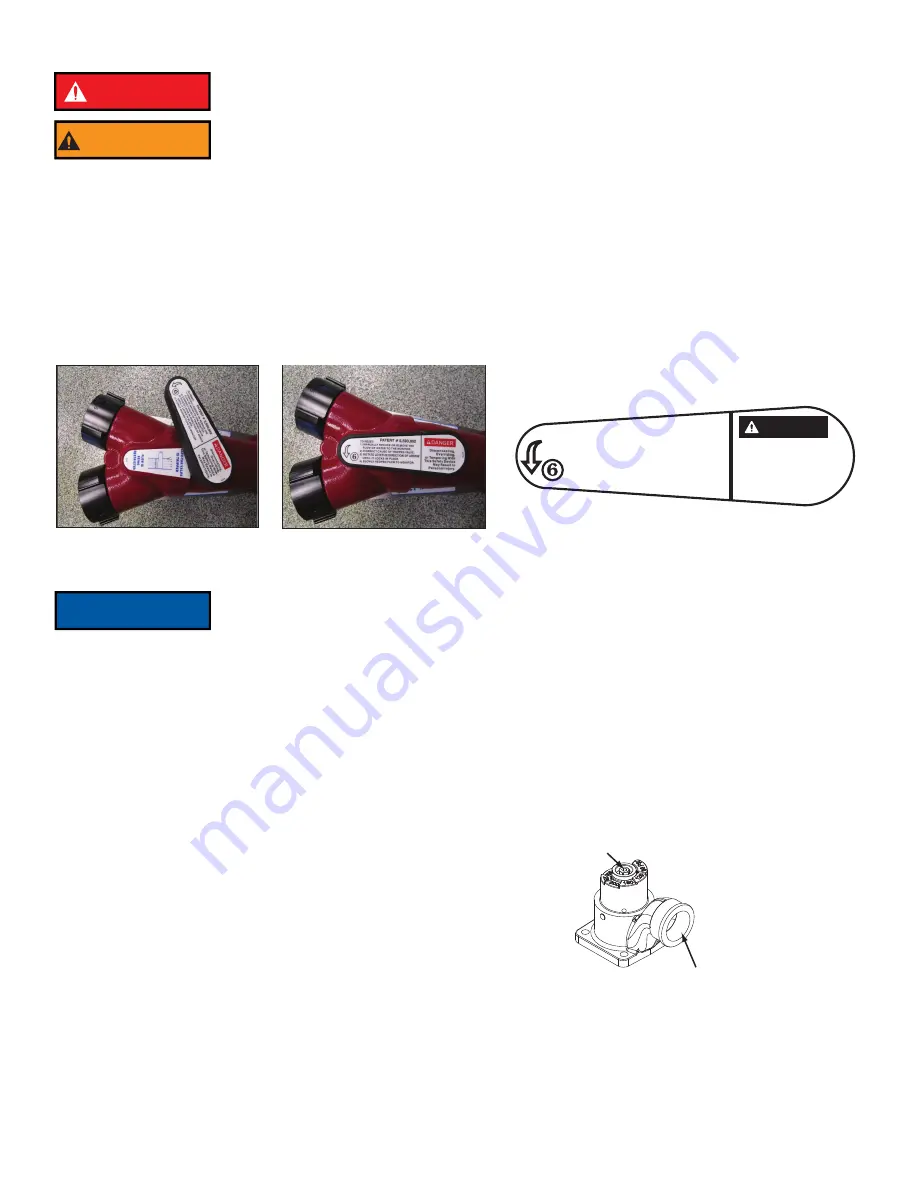

5.6 PORTABLE BASE SAFETY VALVE

The portable base safety valve reduces the flow area through the monitor by 90%, should the base lose contact with the ground for any

reason. In the reduced flow condition, the nozzle reaction force is less and reduces the risk of injury.

The safety valve is spring loaded in the closed position and must be manually set each time the monitor base is deployed or re-located.

To set the safety valve:

1. Rotate the valve handle counter-clockwise until it locks into position, with the handle pointing straight back.

If the safety valve trips:

1. Shut off the flow of water.

2. Determine and correct the cause of trip before resetting safety valve.

3. Rotate the valve handle counter-clockwise until it locks into position, with the handle pointing straight back.

4. Restart water flow.

Figure 5.6

5.7 HOSE CONNECTION

Make the hose connection(s) to the portable base and extend the hose(s) straight back from the portable base at least 10 feet (3

meters). If only one inlet of a double inlet base will be used, a clapper valve will automatically close off the other inlet. Use caution when

turning on the water supply to the monitor on the portable base. As the hose fills, it will become stiff and may cause the monitor and

portable base to slide or tip or both. Open the pumper valve to the monitor slowly.

5.8 PRESSURE RELIEF OPTION

The optional pressure relief valve on the single inlet portable base can be adjusted to open between 90 and 300 psi. The pressure relief

valve, TFT part A1809, is set at the factory to open at 150 psi. To change the relief pressure refer to the label on the bottom side of the

pressure relief valve. A pressure relief valve can be added to the single inlet portable base by removing the cover on the side of the

base. For additional information call 800-348-2686.

5.8.1 PRESSURE RELIEF VALVE SETTING

To set the relief valve pressure turn the adjusting screw on the relief valve

housing until the surface of the screw is even with the desired pressure. Do

not cap or plug discharge opening.

DANGER

Disconnecting, overriding, or tampering with this safety device may result in an out of control

monitor causing severe injury or death. Do not alter the safety valve in any way.

WARNING

While the safety valve reduces flow to the monitor, the remaining flow is still capable of causing

damage and/or injury. Exercise caution around monitor when valve is tripped or being reset. Always

be sure to anchor monitor.

NOTICE

The safety valve responds only to vertical movement of the monitor. To prevent sliding, the monitor

must be properly anchored, even with the safety valve option.

Safety Valve Tripped

(Flow Restricted)

Safety valve Open

(Full Flow Achieved)

D i s c o n n e c t i n g ,

O v e r r i d i n g ,

o r Ta m p e r i n g W i t h

T h i s

S

a f e t y D e v i c e

M a y R e s u l t I n

Pe r s o n a l I n j u r y.

1) MANUALLY REDUCE OR REMOVE THE

FLOW OF WATER TO THE MONITOR.

2) CORRECT CAU

S

E OF TRIPPED VALVE .

3) ROTATE LEVER IN DIRECTION OF ARROW

UNTIL IT LOCK

S

IN PLACE.

4)

S

LOWLY REOPEN FLOW TO MONITOR.

TO RE

S

ET:

X

L

070

PATENT # 5,593,092

DANGER

Portable Base Safety Reset Instruction Label

Adjusting

S

crew

R

elief Valve Discharge Opening

Figure 5.8.1